- Joined

- Jan 13, 2013

- Messages

- 1,510

- Reaction score

- 8

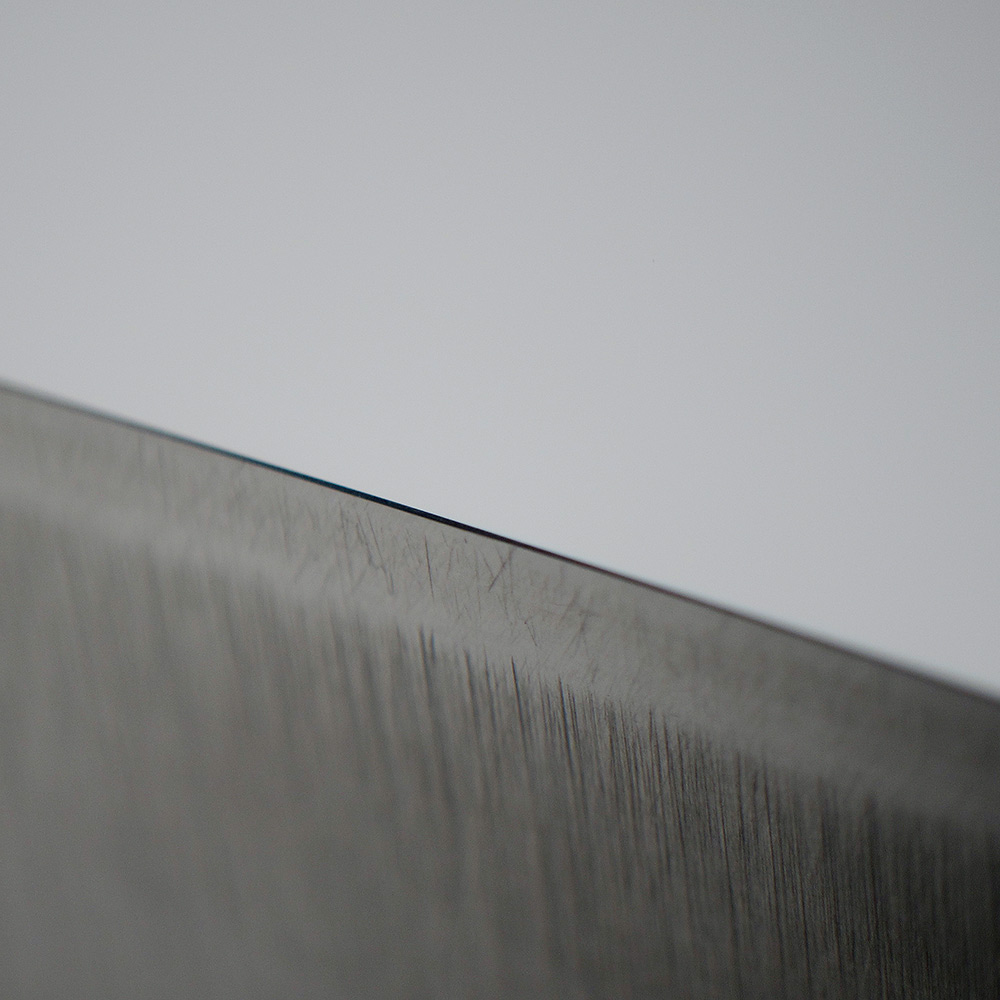

So I have decided to take my carbonext down to a bit more then 16 degrees while maintaining the 60/40 asymmetry, i.e roughly 10/7 I guess. I have seen some people say this is pretty close to the limit for a carbonext and in fact may be pushing it a wee bit. So, of course being a big fan of microbevels on my softer german and american made knives because that allowed me to bring them down to 15 degrees which is pretty much their limit, I was thinking I would put a microbevel on my thinned carbonext.

So my question is: do microbevels work as well on asymmetric knives as they do on symmetric knives?? Logically I don't see why they wouldn't but all the discussions of microbevels I have read was about using them on symmetric knives..

TIA

So my question is: do microbevels work as well on asymmetric knives as they do on symmetric knives?? Logically I don't see why they wouldn't but all the discussions of microbevels I have read was about using them on symmetric knives..

TIA