- Joined

- Mar 18, 2013

- Messages

- 435

- Reaction score

- 57

Here is the other knife she picked up, again for half-a-buck. Can you identify the markings?

( Bigger photos in the gallery here: http://geneh.smugmug.com/Other/Kitchen-Knife/31796417_Q8zQxQ )

(I am helping a coworker who supplements her income reselling antiques and other stuff. On my suggestion she started watching for carbon knifes and landed this unknown knife at a garage sale. I want to clean it up and rehandle it so she can net the most from selling it. So my question is how much should I clean it up with find steel wool and sharpen it, or pretty much leave it alone? What might sell higher? The edge is actually nice, not dished from use / sharpening, but this blade does have a bend in it. It's very thin, light and flexible. Attached are pictures. She would really appreciate anything we can do for her.

Bend in Blade:

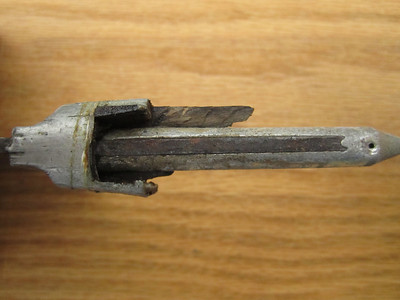

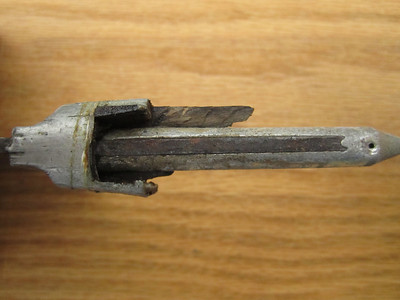

Handle pulled off (ugh, the SMELL!) Showing the bolster and tang.

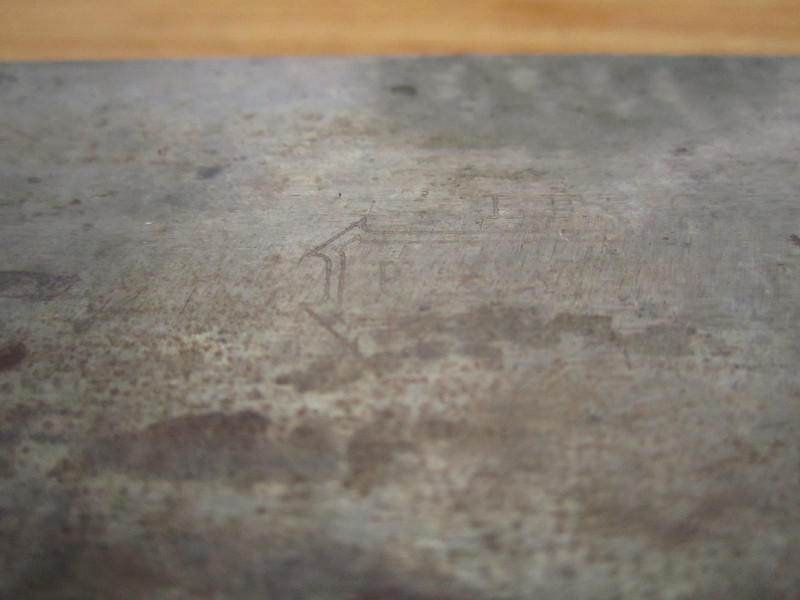

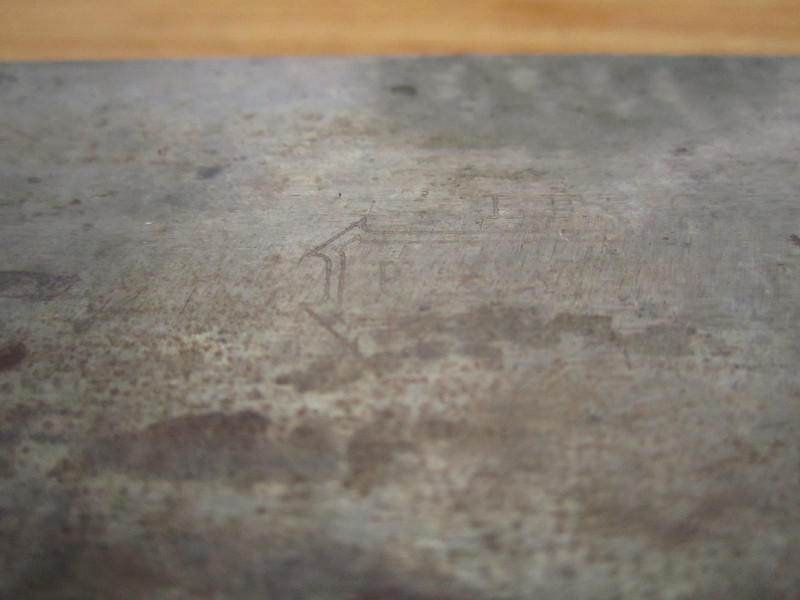

Markings:

( Bigger photos in the gallery here: http://geneh.smugmug.com/Other/Kitchen-Knife/31796417_Q8zQxQ )

(I am helping a coworker who supplements her income reselling antiques and other stuff. On my suggestion she started watching for carbon knifes and landed this unknown knife at a garage sale. I want to clean it up and rehandle it so she can net the most from selling it. So my question is how much should I clean it up with find steel wool and sharpen it, or pretty much leave it alone? What might sell higher? The edge is actually nice, not dished from use / sharpening, but this blade does have a bend in it. It's very thin, light and flexible. Attached are pictures. She would really appreciate anything we can do for her.

Bend in Blade:

Handle pulled off (ugh, the SMELL!) Showing the bolster and tang.

Markings: