WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Thought this one would make an interesting WIP.

I am quite an obsessive about san mai, I have loved it from the very start of my bladesmithing journey. I heat treated and ground san mai before I ever did anything in mono steel In many ways its really good training for how to properly forge taper and grind a blade. As it reveals all shortcomings. I have been really enjoying focusing on some stainless clad san mai recently in plain clad and soft stainless damascus.

In many ways its really good training for how to properly forge taper and grind a blade. As it reveals all shortcomings. I have been really enjoying focusing on some stainless clad san mai recently in plain clad and soft stainless damascus.

So now for a ladder pattern, no room for error what so ever when done in soft clad san mai. Obviously if the core moves too far off centre, you wont have an edge material in places. Or too little balance of cladding or overgrinding, will lead the pattern to get washed too far up the blade, you will have a carbon blade with blobs of stainless.

Hoping for the perfect balance I forged my san mai billet as close to size as I dared before cutting my ladder by hand, as I have no Mill. This when briefly forged down gave me a blade blank tapering from about 4mm to 2mm with a pretty tight even ladder, considering it was hand cut. Everything had to be kept very clean of scale at each process as with forging close to dimensions a few hidden lumps of scale or nasties hammered in could spoil the day.

The starting blank, Heat treated and triple tempered already. .... Possible handle materials...

First step to grinding very much speeded up on new beast of a grinder...

And profile tweaked..

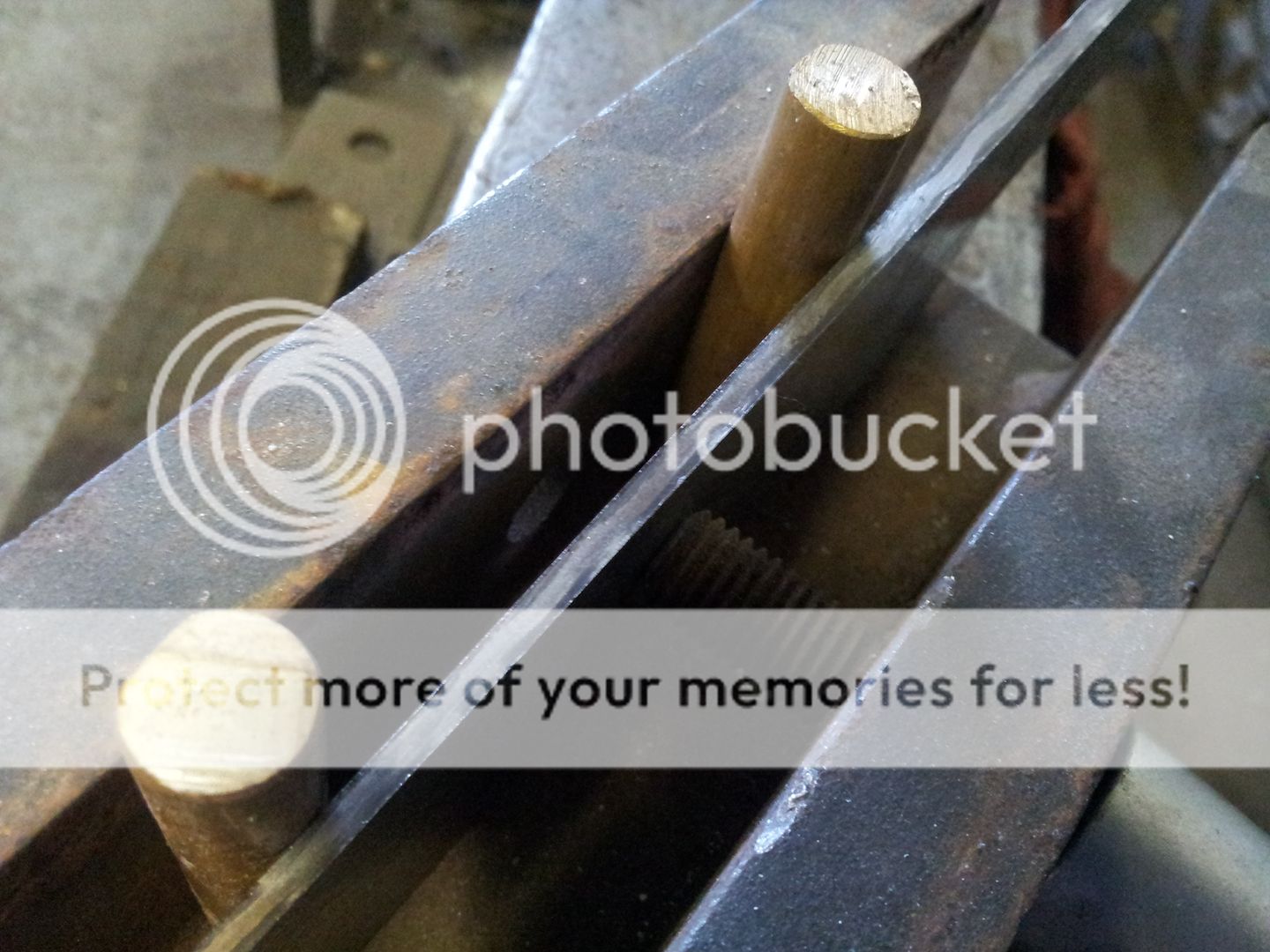

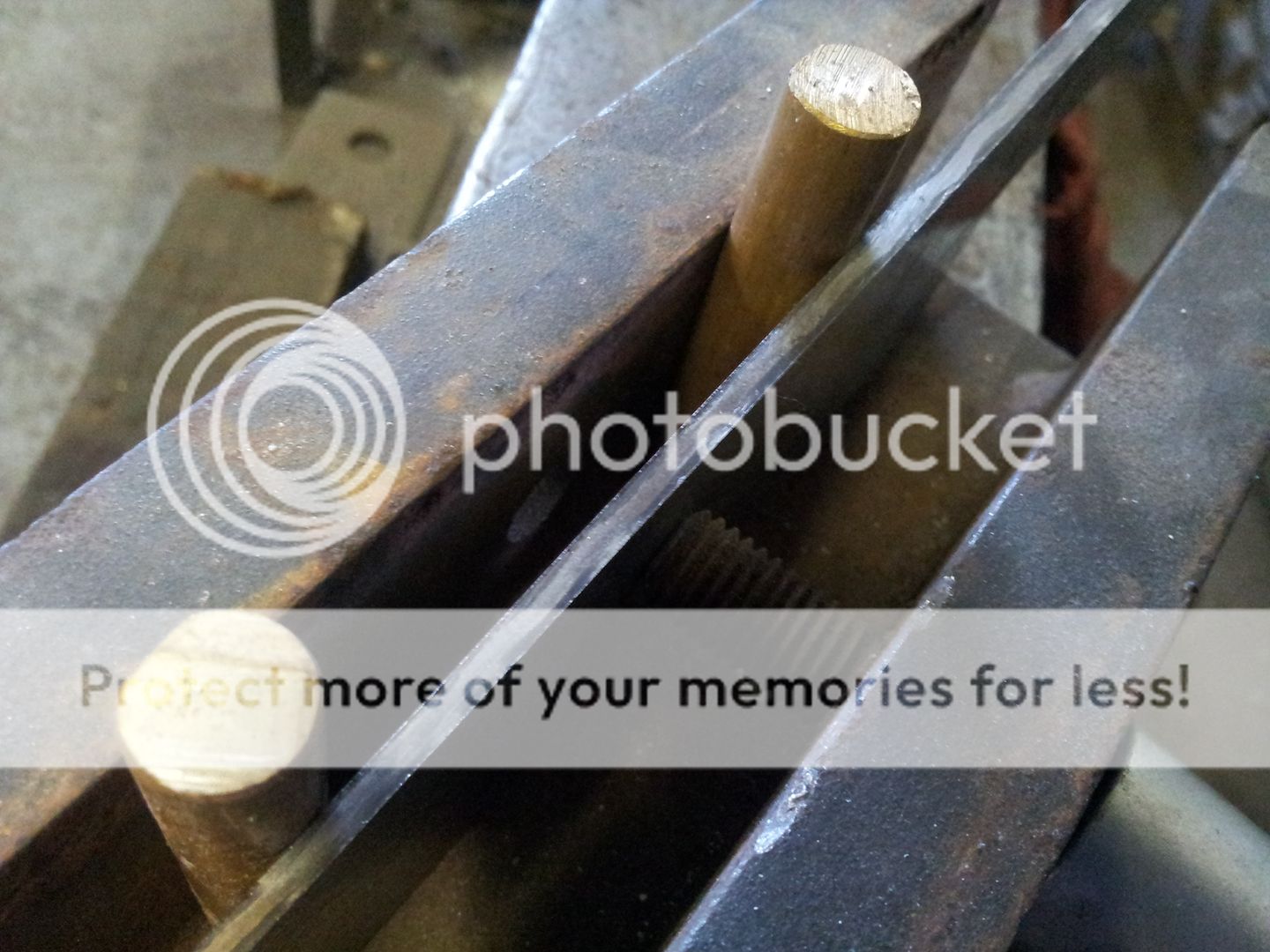

Here is the ladder before grinding the bevels.

A pretty tight ladder, there was room to cut it a bit tighter still, as there were flats inbetween....I want a Mill

Check the even wiggle on the core indicating how the ladder pattern has moved the layers on forging down.

This blank seemed rather more prone to warp than usual, likely as the core is wiggling around. Some careful corrections before grinding.

Now watch carefully, as we grind....hoping the core will hit the centre line all along the edge. Given that the forging stage is done perfectly, grinding is simply like joining the dots.

I check regularly as the grind gets thiner at the edge and rises up the blade.

Plenty of core...

Pretty close now on the double bevels, soon time to blend and convex... Mulling over handle... maybe too garish?

I am quite an obsessive about san mai, I have loved it from the very start of my bladesmithing journey. I heat treated and ground san mai before I ever did anything in mono steel

So now for a ladder pattern, no room for error what so ever when done in soft clad san mai. Obviously if the core moves too far off centre, you wont have an edge material in places. Or too little balance of cladding or overgrinding, will lead the pattern to get washed too far up the blade, you will have a carbon blade with blobs of stainless.

Hoping for the perfect balance I forged my san mai billet as close to size as I dared before cutting my ladder by hand, as I have no Mill. This when briefly forged down gave me a blade blank tapering from about 4mm to 2mm with a pretty tight even ladder, considering it was hand cut. Everything had to be kept very clean of scale at each process as with forging close to dimensions a few hidden lumps of scale or nasties hammered in could spoil the day.

The starting blank, Heat treated and triple tempered already. .... Possible handle materials...

First step to grinding very much speeded up on new beast of a grinder...

And profile tweaked..

Here is the ladder before grinding the bevels.

A pretty tight ladder, there was room to cut it a bit tighter still, as there were flats inbetween....I want a Mill

Check the even wiggle on the core indicating how the ladder pattern has moved the layers on forging down.

This blank seemed rather more prone to warp than usual, likely as the core is wiggling around. Some careful corrections before grinding.

Now watch carefully, as we grind....hoping the core will hit the centre line all along the edge. Given that the forging stage is done perfectly, grinding is simply like joining the dots.

I check regularly as the grind gets thiner at the edge and rises up the blade.

Plenty of core...

Pretty close now on the double bevels, soon time to blend and convex... Mulling over handle... maybe too garish?