Burl Source

Weird Wood Pusher

- Joined

- Jun 13, 2011

- Messages

- 4,340

- Reaction score

- 7

Below I show the method I like best for finishing stabilized woods. This also works well for most natural hardwoods.

I took a lot of shortcuts so if you do things correctly your results will look much better than the photos below.

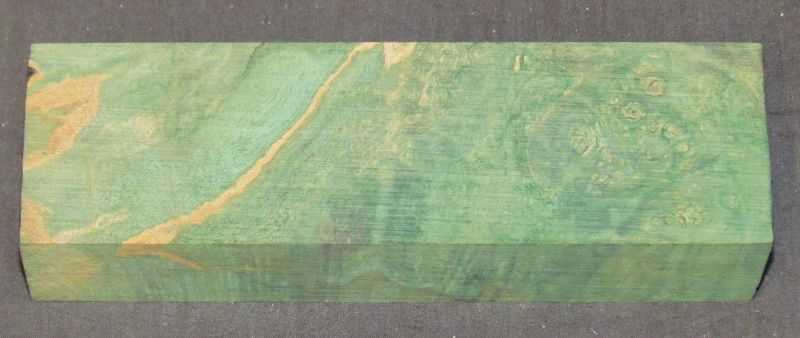

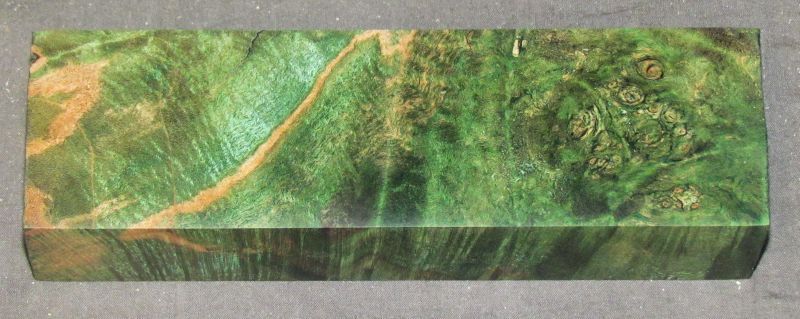

This is a reject block of maple burl that was dyed and stabilized by K&G. Sanded to 80 grit.

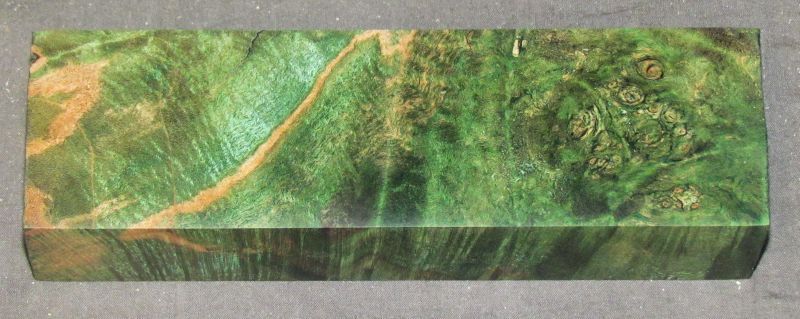

Sanded to 400 grit

Sanded to 600 grit. You can see that 600 grit is when the wood starts looking good. The finer you go from here the more defined the grain and figure become. I stopped at 600 grit because that was the finest sandpaper I had on hand. Best results come at 1000+ grit.

Using an oil blend like Danish Oil or Tung oil I wipe on a light coat. The reason I prefer an oil blend over something like linseed oil is because the blend tends to fill small pores especially with multiple coats.

After 15 or 20 minutes I wipe down the wood with a dry cloth. I let that sit and dry for a couple hours and then apply another coat. Repeat until everything looks good to you.

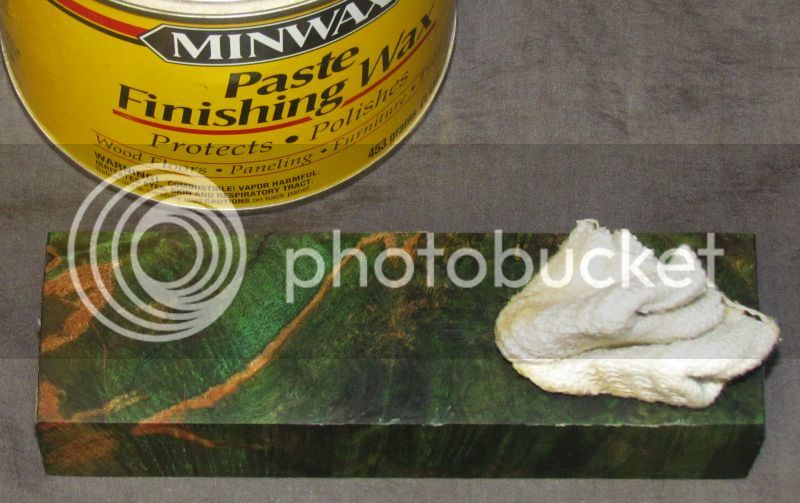

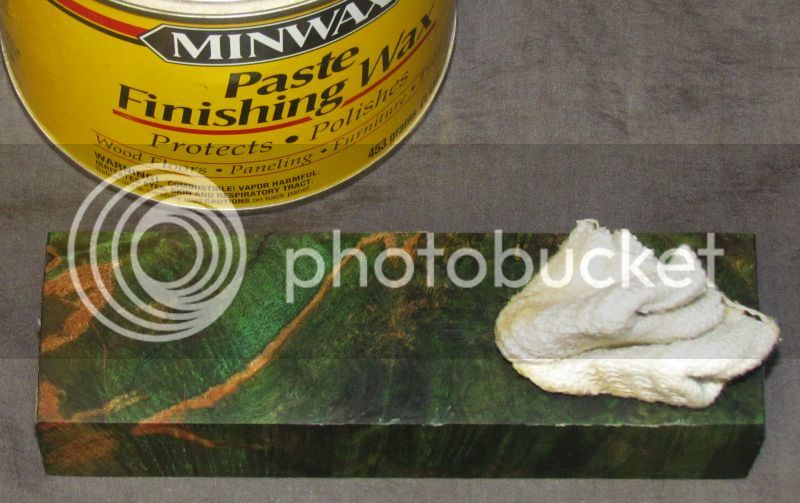

After letting the handle dry overnight I apply a generous coat of paste wax.

Then about an hour later I hand buff with a soft cloth. Like polishing a pair of shoes.

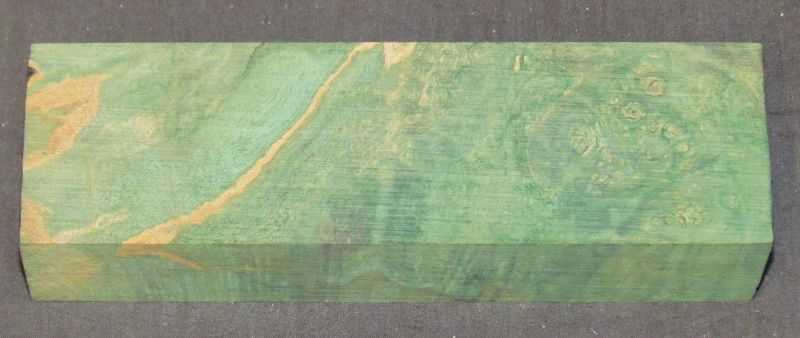

These photos show the block sanded to 600 grit and only one coat of Danish Oil. If you sand your handle to 1000+ grit and apply 3 or 4 coats of oil your results will be much better.

I took a lot of shortcuts so if you do things correctly your results will look much better than the photos below.

This is a reject block of maple burl that was dyed and stabilized by K&G. Sanded to 80 grit.

Sanded to 400 grit

Sanded to 600 grit. You can see that 600 grit is when the wood starts looking good. The finer you go from here the more defined the grain and figure become. I stopped at 600 grit because that was the finest sandpaper I had on hand. Best results come at 1000+ grit.

Using an oil blend like Danish Oil or Tung oil I wipe on a light coat. The reason I prefer an oil blend over something like linseed oil is because the blend tends to fill small pores especially with multiple coats.

After 15 or 20 minutes I wipe down the wood with a dry cloth. I let that sit and dry for a couple hours and then apply another coat. Repeat until everything looks good to you.

After letting the handle dry overnight I apply a generous coat of paste wax.

Then about an hour later I hand buff with a soft cloth. Like polishing a pair of shoes.

These photos show the block sanded to 600 grit and only one coat of Danish Oil. If you sand your handle to 1000+ grit and apply 3 or 4 coats of oil your results will be much better.