Burl Source

Weird Wood Pusher

- Joined

- Jun 13, 2011

- Messages

- 4,340

- Reaction score

- 7

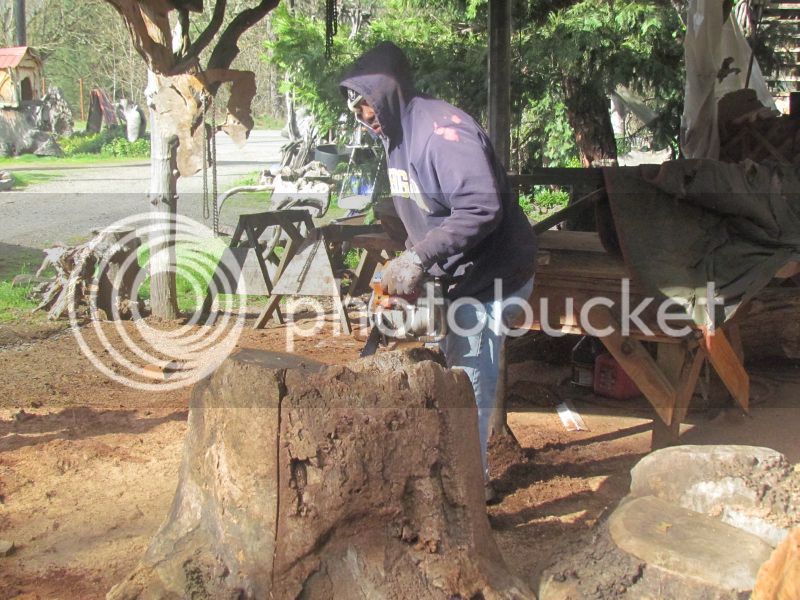

Yesterday was spent driving into the mountains to see a guy who has some really good walnut. Most of the walnut this guy has is veneer grade burls and high end gun stock material. While we were talking yesterday one of his gun stock blanks sold on line for $2500. This is the wood I got from him this trip. When finances allow I plan to get a lot more from him. You can't tell from the photos but this is some very good, old walnut.

I am excited about this big stump. It will have a sort of figure called shimmer by the gun stock makers. Quarter sawn it should show fiddleback figure.

We will start cutting these up pretty soon and I will take more photos.

I am excited about this big stump. It will have a sort of figure called shimmer by the gun stock makers. Quarter sawn it should show fiddleback figure.

We will start cutting these up pretty soon and I will take more photos.