Does anyone have any good tips on making a traditional Japanese handle? I've tried a few methods but I haven't managed a proper traditional handle yet. I keep changing the handles on my knives one by one and getting better but I'm still not happy.

I'd like to make a wooden handle with an oval tenon and then attatching a hot horn ferrule (mortise) over it, the way it is on many Japanese knives (or at least how I'm used to seeing them).

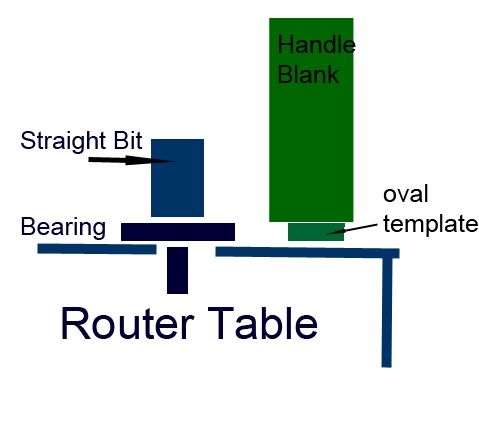

The trick question is how do you make a smooth oval tenon? So far I've made them by hand with a knife. And then drilled a round hole through a ferrule and heated it till soft and pressed on. But it's fairly difficult and doesn't end up pretty.

I might be ok with using a bit of glue to make the seal permanent but using a dowel isn't my favorite idea. It's very easy to use a lathe and make the tenon round and press on a round ferrule. But that looks wrong then the tang is fairly thin and high. You end up with a really thin ferrule or the tang slot goes right into the horn.

If there was a good method of making an oval tenon and a matching oval hole it would be great!

http://fxcuisine.com/default.asp?language=2&Display=241&resolution=low&page=2

Thanks guys!

I'd like to make a wooden handle with an oval tenon and then attatching a hot horn ferrule (mortise) over it, the way it is on many Japanese knives (or at least how I'm used to seeing them).

The trick question is how do you make a smooth oval tenon? So far I've made them by hand with a knife. And then drilled a round hole through a ferrule and heated it till soft and pressed on. But it's fairly difficult and doesn't end up pretty.

I might be ok with using a bit of glue to make the seal permanent but using a dowel isn't my favorite idea. It's very easy to use a lathe and make the tenon round and press on a round ferrule. But that looks wrong then the tang is fairly thin and high. You end up with a really thin ferrule or the tang slot goes right into the horn.

If there was a good method of making an oval tenon and a matching oval hole it would be great!

http://fxcuisine.com/default.asp?language=2&Display=241&resolution=low&page=2

Thanks guys!