Chuckles,

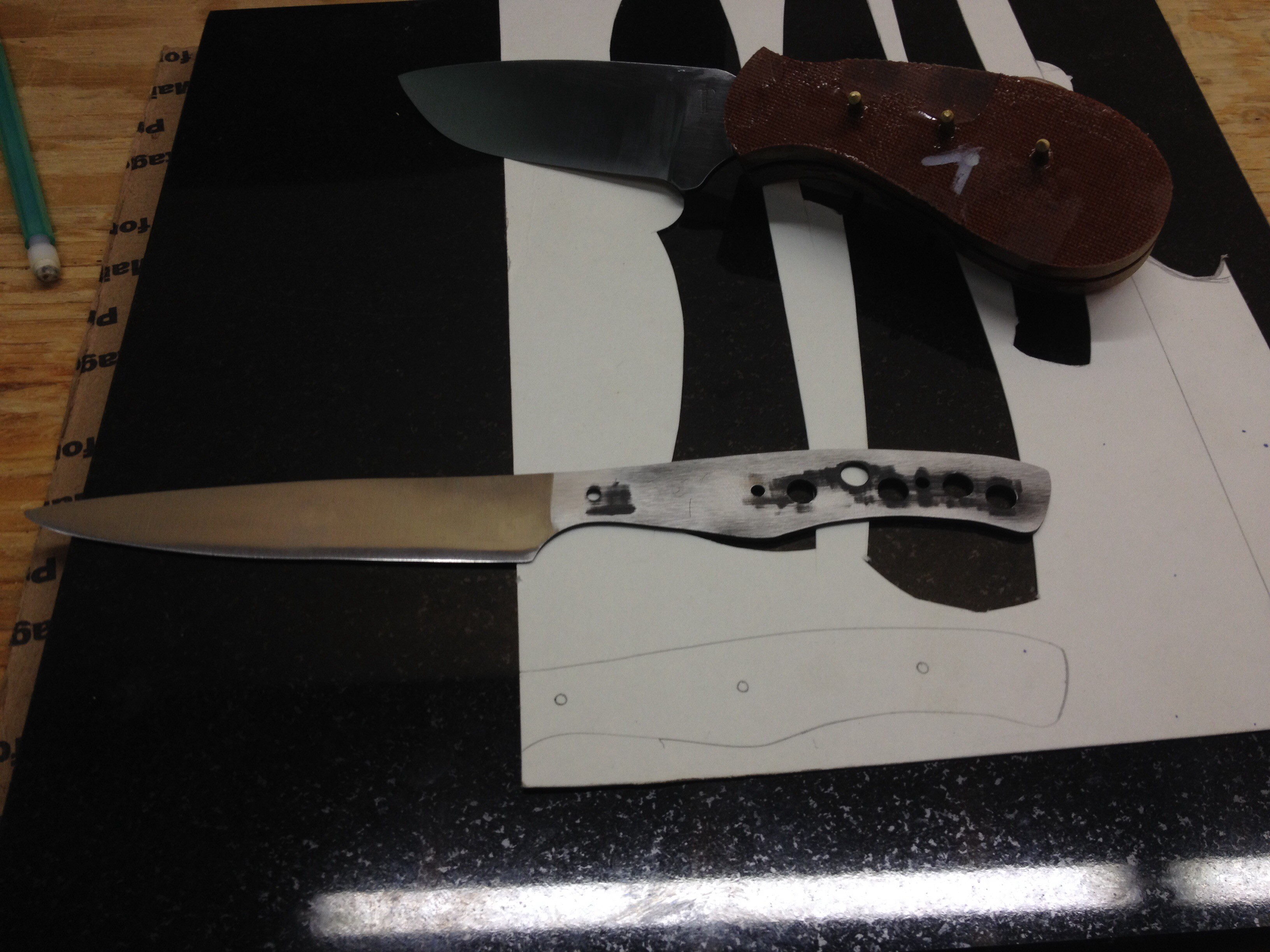

I did hand sand the blade prior to HT to remove any deep scratches from the 36 grit and 120 grit blaze belts. I learned this lesson when I made my first two knives as I was unable to remove scratches that had not been removed pre-HT.

Variable speed is definitely a game changer in terms of being able to control just how fast the belts hog off material, which is very helpful when learning the process. Also, once heat treated, being able to adjust the speed is crucial to getting thin grinds without ruining the temper, at least from what I understand.

It was easier in terms of being able to remove material incredibly quickly versus using hand files, which is what I used the for the first two knives. Cutting the steel, profiling and drilling would take me literally all day, now it takes 30 minutes including switching out tool arms for the grinder. The danger here is that I can do an amazing amount of damage very quickly if I am not paying attention.

The attachments for the grinder also provide the ability to make a much more precise flat grind or hollow grind. Overall I can do much more now than what is possible with files.