WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

I have been very focused on my Damascus and san mai work for sometime and regularly get inquires about mono steel knives. So with a considered approach I mean to make a few every now and then which will be for direct sale as and when they are produced via my mailing list and website.

In a current mono steel I want to offer a similar grind weight and geometry that I have come to offer in my custom damascus work so will be making some from thicker 4mm stock as well as some lighter in 3mm as the original Utility line were.

The 4mm will be pitched as a higher grade product, giving you the benefit of my current geometry, heavier knife, thin geometry, the same finish and attention to detail will be given to the 3mm knives, you will just have a lighter knife, well mid weight, I would say close to 4mm is mid as well, anything over that being heavy. Handles will be made from what I have and can attain at a mid/reasonable price and from bits and pieces I have. So rarely two will be the same handle mixture, will only be using stabilised or very stable natural stock. I stress that these will all be completely hand made in shop and in no way mid-tech.

I will post pictures here as they get finished and detail geometry shots so you can see what Im talking about.

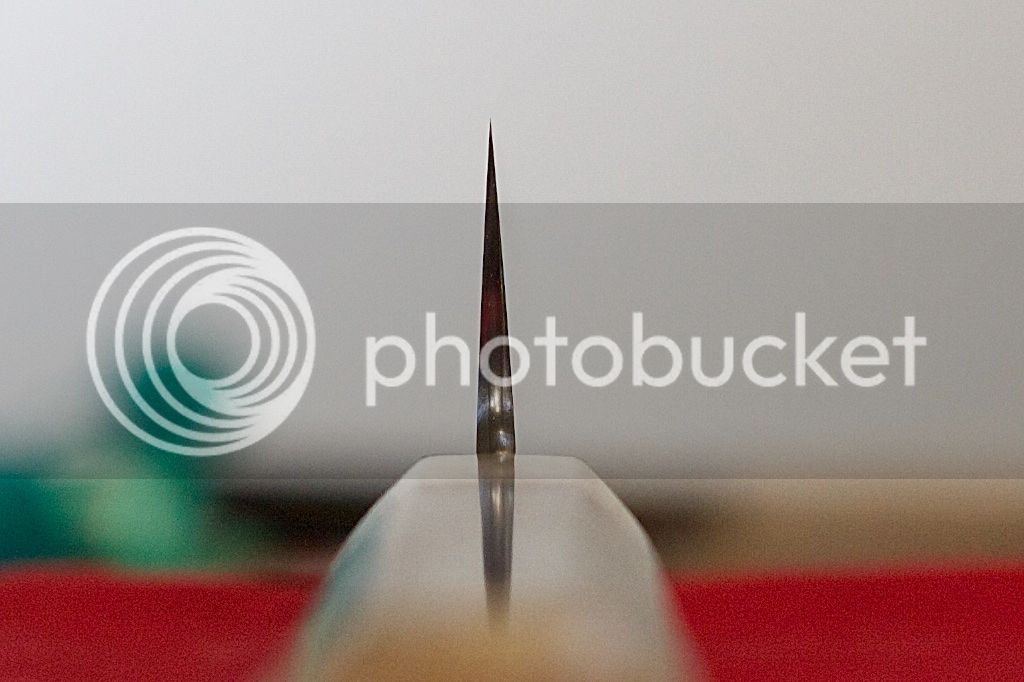

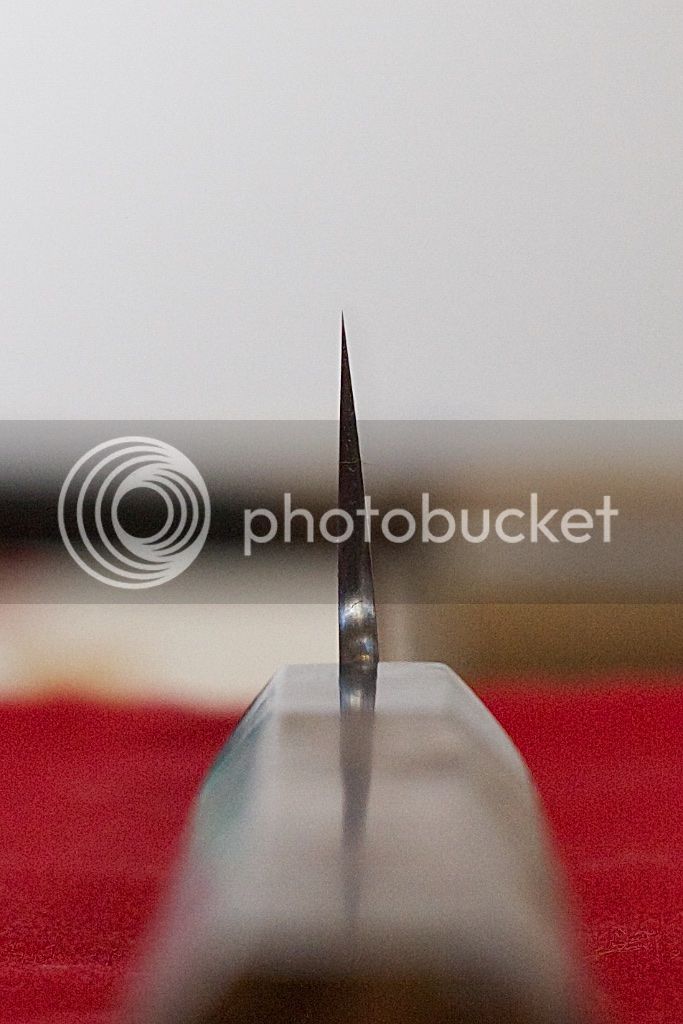

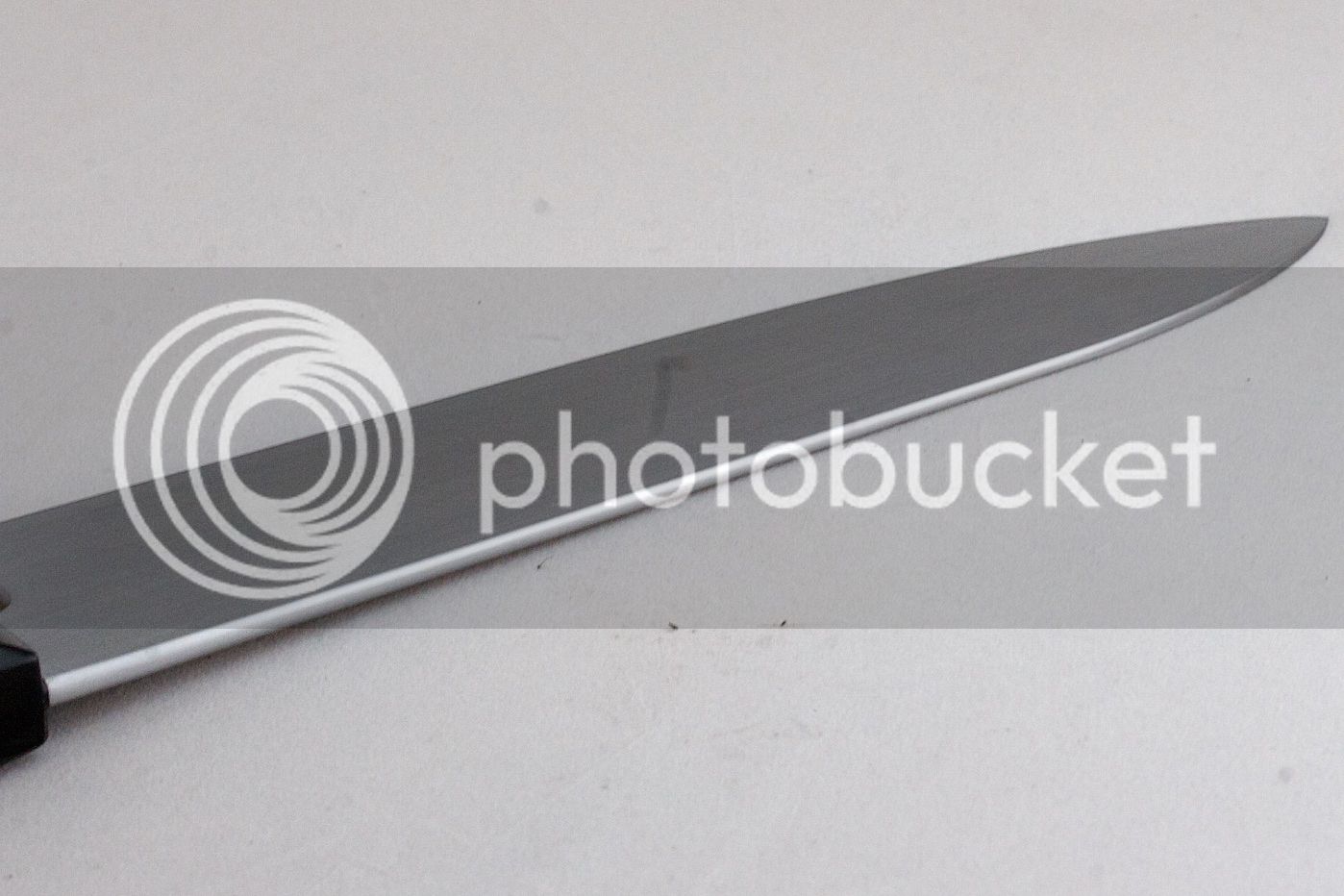

Here is the first in 4mm carbon 01. Will be about 3.8mm at the heel, very pleased the way it feels, and cuts like a custom.

It is a 230mm Gyuto, 52mm Height.

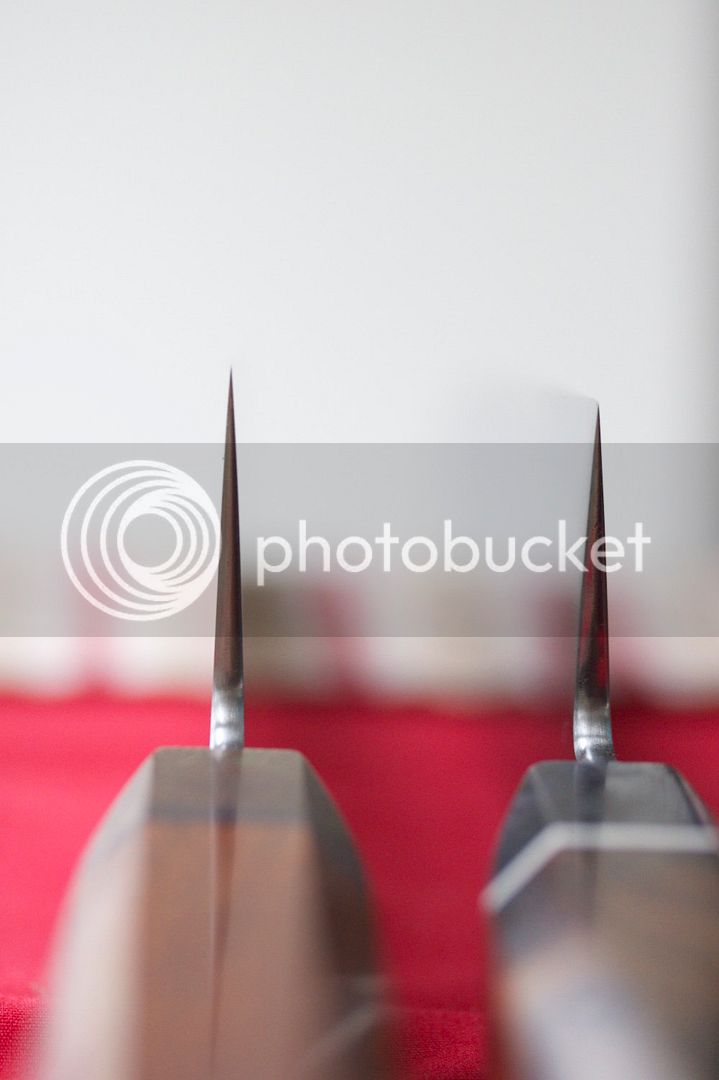

Lets get straight to the geometry, excuse the fluff on the blade, Macro lens is very unforgiving

I have price points in mind for both the 3mm and 4mm offerings and will publish a couple for sale soon via my mailing then place them for sale on my website.

Would love to know what you think of this,

Cheers

Will

In a current mono steel I want to offer a similar grind weight and geometry that I have come to offer in my custom damascus work so will be making some from thicker 4mm stock as well as some lighter in 3mm as the original Utility line were.

The 4mm will be pitched as a higher grade product, giving you the benefit of my current geometry, heavier knife, thin geometry, the same finish and attention to detail will be given to the 3mm knives, you will just have a lighter knife, well mid weight, I would say close to 4mm is mid as well, anything over that being heavy. Handles will be made from what I have and can attain at a mid/reasonable price and from bits and pieces I have. So rarely two will be the same handle mixture, will only be using stabilised or very stable natural stock. I stress that these will all be completely hand made in shop and in no way mid-tech.

I will post pictures here as they get finished and detail geometry shots so you can see what Im talking about.

Here is the first in 4mm carbon 01. Will be about 3.8mm at the heel, very pleased the way it feels, and cuts like a custom.

It is a 230mm Gyuto, 52mm Height.

Lets get straight to the geometry, excuse the fluff on the blade, Macro lens is very unforgiving

I have price points in mind for both the 3mm and 4mm offerings and will publish a couple for sale soon via my mailing then place them for sale on my website.

Would love to know what you think of this,

Cheers

Will