stereo.pete

Senior Member

- Joined

- Mar 2, 2011

- Messages

- 2,398

- Reaction score

- 366

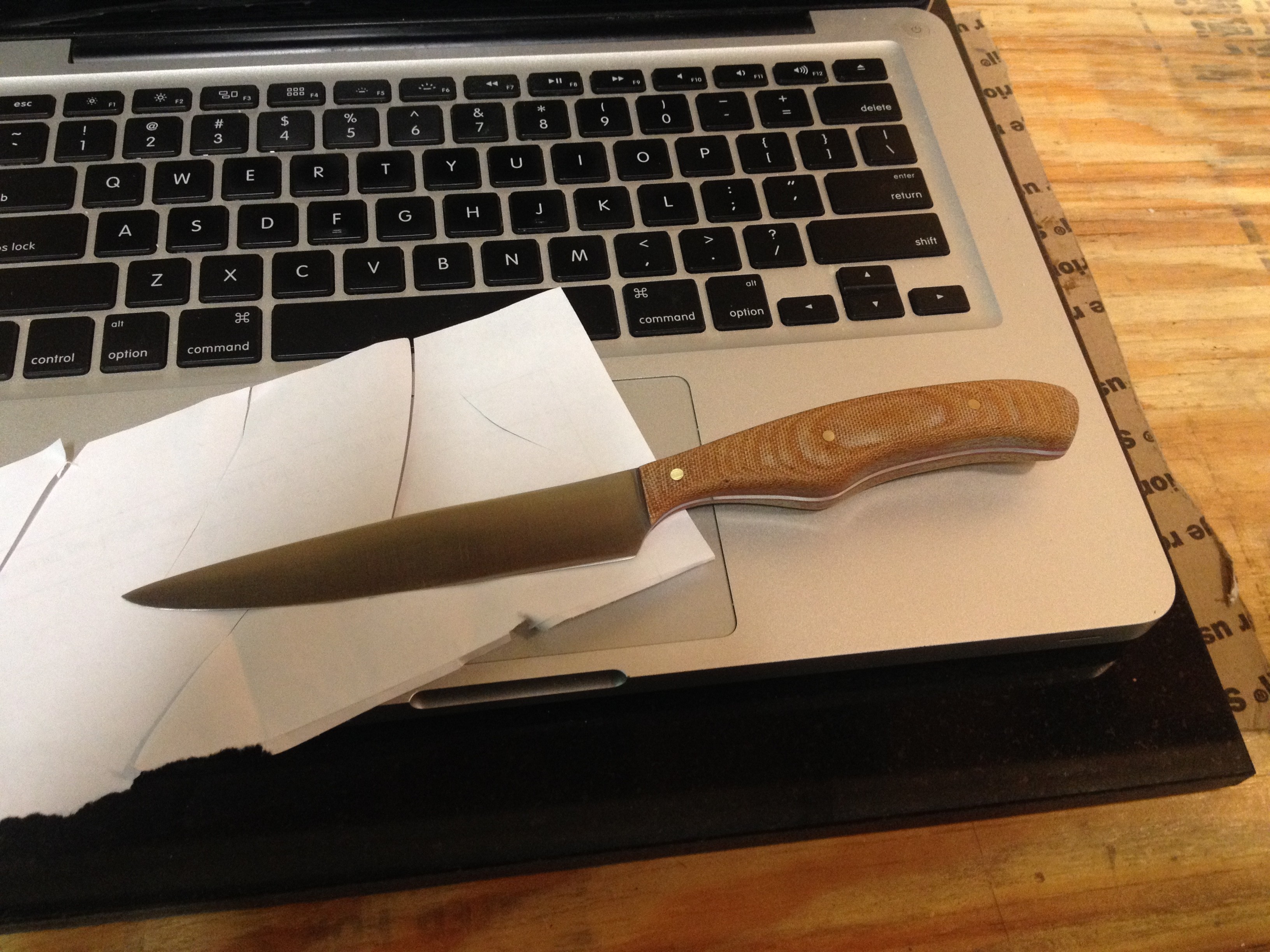

Here's the handle I just finished shaping/sanding on a new petty/pairing knife I am working on.

Thanks guys looking guys and Dave, thanks for the heads up about G10 as a liner material. Does anyone know what Bob Loveless used for his famous red liners on his knives?

Enter your email address to join: