stereo.pete

Senior Member

- Joined

- Mar 2, 2011

- Messages

- 2,398

- Reaction score

- 366

Here's a honesuki that I am working on, which is made out of 5/32 O1 stock. It will be deba-ish in terms of thickness so we'll see how she does in testing. This knife will also be my first with a wa-handle. Any questions or concerns with the shape of the blade or the tang? I also hollow ground this knife as it will be strictly for protein prep, primarily deboning chickens, any issues? Also, any suggestions as to what hardness and why?

Thanks in advance for looking :wink:

My inspiration

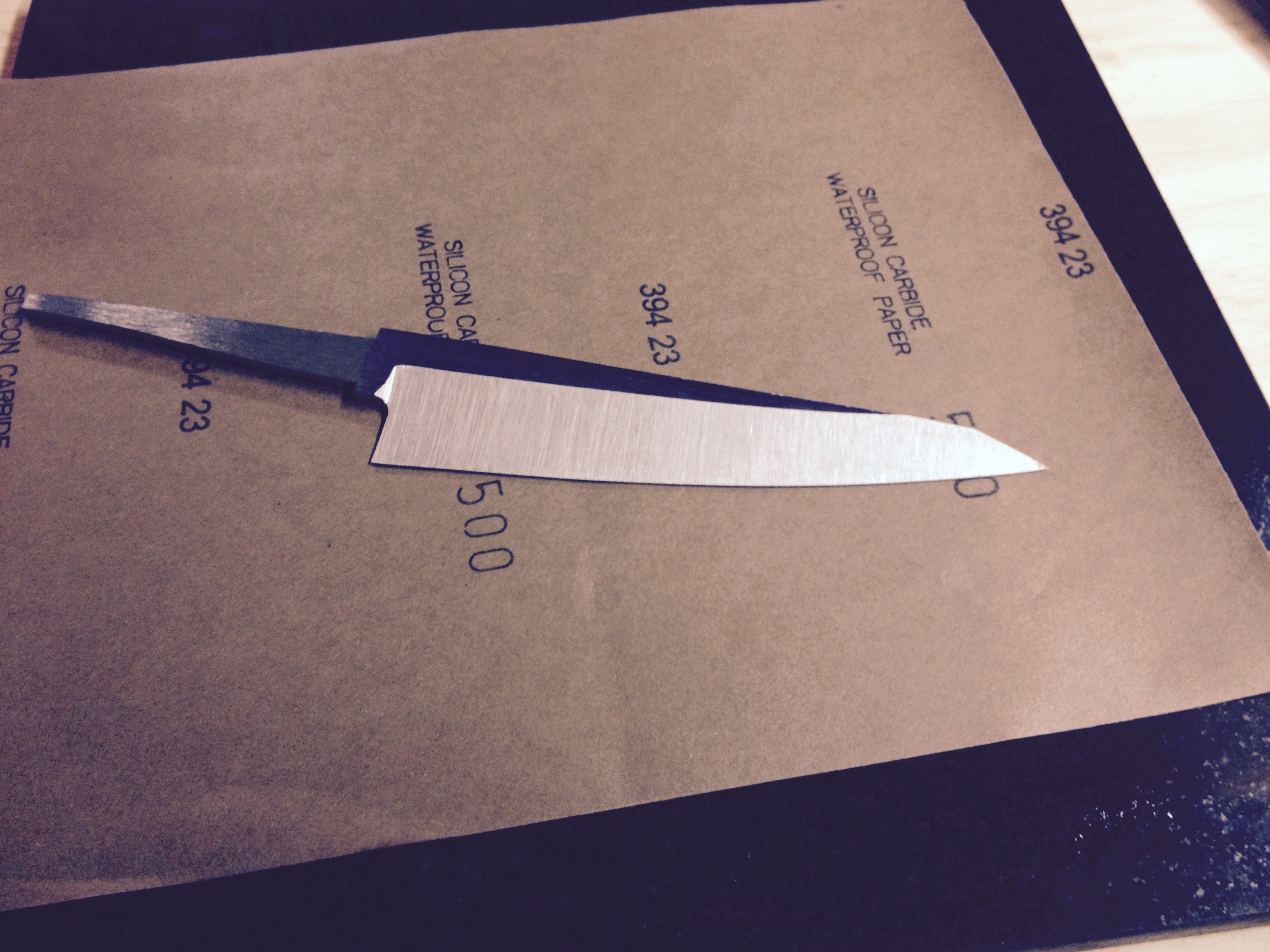

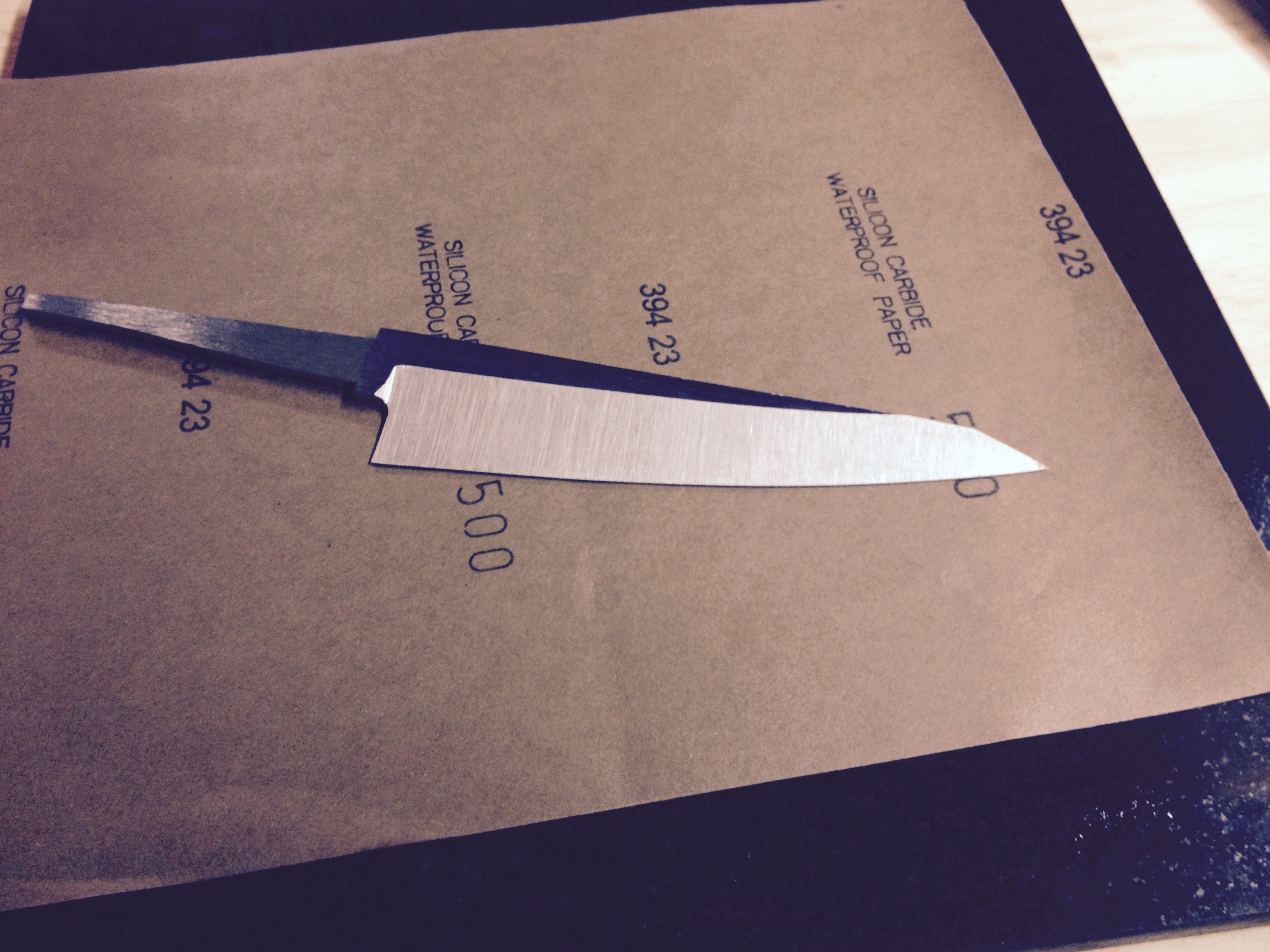

Pre-heat treatment grinding finished

Thanks in advance for looking :wink:

My inspiration

Pre-heat treatment grinding finished