Disclaimer - this will be a long one, so let me start with a photo

I have just received from Andy Billipp my brand new damascus gyuto. I am completely overwhelmed with the first impressions. It was clear that sooner than later I would make a review, but I have decided to divide it in two parts. The first part will be basically my first impressions and photos of brand new, yet to be used, knife. Second part will come later after I have some hands-on experience and will also include some thoughts on how does it compare to other knives that I have at hand at the moment.

Introduction:

I have learned about Andy's work via KKF and got immediately attracted by the way Andy finishes his knives - combination of rustic look and amazing handle together with very interesting blade profiles. It took me a few months to get there, but eventually I got on Andy's waiting list by the mid summer 2014. Quoted waiting time was about 6 months, what turned to be 7 months - so rather on spot. While the waiting list at the time was short, Andy became a father sometimes in August and together with high farming season it was not until late Autumn that the project could get started. Until that time I was so 'worked up' that I decided to go with the damascus version.

About Andy:

I asked Andy he got to making kitchen knives and was surprised by the answer. While he did have life-long interest in knives, it was finally his wife (who studied Scandinavian woodworking and has her own shop) to go ahead and give it a try. The really interesting part is that he did not apprentice with anyone (though he admitted that that's would have been the way to go), but just used the information available online and use the trial-and-error method (lot't of error according to Andy, even today). The choice of kitchen knives was made base on what kind of knives he uses most (Andy calls his homelife 'food centred').

Knife design:

Contrary to other makers, Andy does not really like to deviate from what he considers works well and what he has experience with when it comes to blade material, heat-treat, blade geometry or grind. The reason is simple - he got to certain design and process that he finds working well (though he is open to new/custom projects - our first discussion was about honesuki knives - something he has not done yet). I new that beforehand and indeed I did not have intentions to dictate Andy how the blade should be ground, how thick it should be at the spine and so on. I have basically specified (roughy) the blade length and width and I have him my preferences on the blade profile. Concerning the handle he had some materials to choose from. I also had option to provide my own wood, but he had some really lovely blocks, so I picked one of those.

Materials and dimensions:

As mentioned the core cutting steel is 52100. Andy hardens the steel to about HRC61. The interesting part is the damascus cladding. It is made from 1084 and 15n20 what means that it also hardens during the heat treatment as these steels react somewhat similarly as the core steel, what according to Andy gives less probability of warping or delimitation. To avoid the knife being too hard and potentially fragile - the spine and bolster area are softened to 'spring hardness'. The result is still a rather stiff knife.

This knife dimensions are the following:

weight: 268g (yep!)

heel-to-tip: 255 mm

height at the heel: 51 mm

spine at the bolster: 9.0 mm

spine at the heel: 7.0 mm

spine at the "B": 3.0 mm

spine 1/2 towards the tip: 2.2 mm

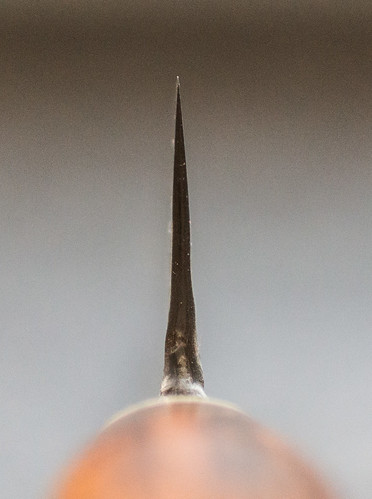

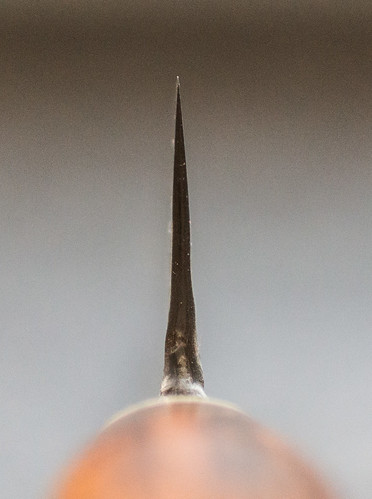

spine 1cm from the tip: 0.7mm

handle length: 130 mm

So as you can see - this knife is definitely on the workhorse side and with weight of nearly 270g it is very comparable to a Kato Workhorse. Prior receiving the knife I was a bit worried that because of the thick neck and ironwood handle the knife could feel butt-heavy, but that is not the case. The centre of mass is about 1 cm from the heel towards the tip - or where you put your index finger with a pinch grip. This makes the knife feel very nimble. Compared to Kato which has centre of mass 2-3 cm further towards the tip (which makes it a great chopper and accounts for that 'separate that food' feel. The position of the centre of mass makes the knife feel lighter that it is (Kato does feel heavier in hand)

Blade finish:

Hard to miss this point, really The blade has really rustic-looking hand forged finish. The random damascus pattern is very lively and blends wonderfully with that 3D forged finish.

Profile and geometry:

In spite of being rather beefy, the blade is ground very thin behind the edge - a quick thumbnail test confirms that. The knife arrived shaving sharp so I have no reason to take it to stone right away. That will be, after all, part of the next review.

If you look at the choil shot you can see not only the knife being thin behind the edge, but also how it gets thicker towards the spine. Given the thick neck of the knife (which only tapers to 'normal' spine at around the letter 'B' the first 1cm or so from the heel the knife gets thicker getting away from the edge a lilt faster than the rest of the blade, so that choil shot should not be 'over-interpreted', so to speak.

I was very surprised when I measured the blade length for the first time - for some reason I would have guessed less than 240mm - maybe because of rather long handle. The knife just does not feel this large/long in your hand.

When you look at the blade profile you can see, that the knife has rather long flat spot - about 10cm. At the same time - the handle (and spine) are not parallel to this flat part, but have a slight angle relative to it. This allows for the blade to slowly decrease the blade height towards the tip without too much belly or without the the blade being a 'drop point'. I am not going to claim any superiority of that design (not before actually getting the knife a proper workout), but I do like the the way it looks. The blade seems to have second flat spot (though not completely flat) towards the tip.

For comparison - profile of a Kato Workhorse

Handle:

The handle is lovely - fit & finish is perfect and I would not hesitate to compare it to the level of that of the rosewood handle Dave did for us recently (which is magnificent). In particular the fit of the brass bolster to the hand forged neck of the knife is perfect what just magnifies the difference between the perfectly finished handle and the hand forged finish of the blade. It sits very well in hand and feels best with pinch grip. It is also long enough - I can hardly imagine that someone could find it too small or short.

Choil, spine & bolster:

The choil (as well as the spine) are semi-rounded and very comfortable. The rounding was mostly made with hammer, so you do not get shiny polished area that would not fit so nicely with the finish of the blade.

Not to forget the sheath - it is a simple, but elegant one made from a very thick leather. The knife fits snugly and actually some force is needed to push the last 1-2 cm of the draw, so the sheath sits securely on the blade and does not require any additional attachment system.

OK - that is it for now. In the mean time the knife has made it first cuts, but that is to be reported in the second part.

I have just received from Andy Billipp my brand new damascus gyuto. I am completely overwhelmed with the first impressions. It was clear that sooner than later I would make a review, but I have decided to divide it in two parts. The first part will be basically my first impressions and photos of brand new, yet to be used, knife. Second part will come later after I have some hands-on experience and will also include some thoughts on how does it compare to other knives that I have at hand at the moment.

Introduction:

I have learned about Andy's work via KKF and got immediately attracted by the way Andy finishes his knives - combination of rustic look and amazing handle together with very interesting blade profiles. It took me a few months to get there, but eventually I got on Andy's waiting list by the mid summer 2014. Quoted waiting time was about 6 months, what turned to be 7 months - so rather on spot. While the waiting list at the time was short, Andy became a father sometimes in August and together with high farming season it was not until late Autumn that the project could get started. Until that time I was so 'worked up' that I decided to go with the damascus version.

About Andy:

I asked Andy he got to making kitchen knives and was surprised by the answer. While he did have life-long interest in knives, it was finally his wife (who studied Scandinavian woodworking and has her own shop) to go ahead and give it a try. The really interesting part is that he did not apprentice with anyone (though he admitted that that's would have been the way to go), but just used the information available online and use the trial-and-error method (lot't of error according to Andy, even today). The choice of kitchen knives was made base on what kind of knives he uses most (Andy calls his homelife 'food centred').

Knife design:

Contrary to other makers, Andy does not really like to deviate from what he considers works well and what he has experience with when it comes to blade material, heat-treat, blade geometry or grind. The reason is simple - he got to certain design and process that he finds working well (though he is open to new/custom projects - our first discussion was about honesuki knives - something he has not done yet). I new that beforehand and indeed I did not have intentions to dictate Andy how the blade should be ground, how thick it should be at the spine and so on. I have basically specified (roughy) the blade length and width and I have him my preferences on the blade profile. Concerning the handle he had some materials to choose from. I also had option to provide my own wood, but he had some really lovely blocks, so I picked one of those.

Materials and dimensions:

As mentioned the core cutting steel is 52100. Andy hardens the steel to about HRC61. The interesting part is the damascus cladding. It is made from 1084 and 15n20 what means that it also hardens during the heat treatment as these steels react somewhat similarly as the core steel, what according to Andy gives less probability of warping or delimitation. To avoid the knife being too hard and potentially fragile - the spine and bolster area are softened to 'spring hardness'. The result is still a rather stiff knife.

This knife dimensions are the following:

weight: 268g (yep!)

heel-to-tip: 255 mm

height at the heel: 51 mm

spine at the bolster: 9.0 mm

spine at the heel: 7.0 mm

spine at the "B": 3.0 mm

spine 1/2 towards the tip: 2.2 mm

spine 1cm from the tip: 0.7mm

handle length: 130 mm

So as you can see - this knife is definitely on the workhorse side and with weight of nearly 270g it is very comparable to a Kato Workhorse. Prior receiving the knife I was a bit worried that because of the thick neck and ironwood handle the knife could feel butt-heavy, but that is not the case. The centre of mass is about 1 cm from the heel towards the tip - or where you put your index finger with a pinch grip. This makes the knife feel very nimble. Compared to Kato which has centre of mass 2-3 cm further towards the tip (which makes it a great chopper and accounts for that 'separate that food' feel. The position of the centre of mass makes the knife feel lighter that it is (Kato does feel heavier in hand)

Blade finish:

Hard to miss this point, really The blade has really rustic-looking hand forged finish. The random damascus pattern is very lively and blends wonderfully with that 3D forged finish.

Profile and geometry:

In spite of being rather beefy, the blade is ground very thin behind the edge - a quick thumbnail test confirms that. The knife arrived shaving sharp so I have no reason to take it to stone right away. That will be, after all, part of the next review.

If you look at the choil shot you can see not only the knife being thin behind the edge, but also how it gets thicker towards the spine. Given the thick neck of the knife (which only tapers to 'normal' spine at around the letter 'B' the first 1cm or so from the heel the knife gets thicker getting away from the edge a lilt faster than the rest of the blade, so that choil shot should not be 'over-interpreted', so to speak.

I was very surprised when I measured the blade length for the first time - for some reason I would have guessed less than 240mm - maybe because of rather long handle. The knife just does not feel this large/long in your hand.

When you look at the blade profile you can see, that the knife has rather long flat spot - about 10cm. At the same time - the handle (and spine) are not parallel to this flat part, but have a slight angle relative to it. This allows for the blade to slowly decrease the blade height towards the tip without too much belly or without the the blade being a 'drop point'. I am not going to claim any superiority of that design (not before actually getting the knife a proper workout), but I do like the the way it looks. The blade seems to have second flat spot (though not completely flat) towards the tip.

For comparison - profile of a Kato Workhorse

Handle:

The handle is lovely - fit & finish is perfect and I would not hesitate to compare it to the level of that of the rosewood handle Dave did for us recently (which is magnificent). In particular the fit of the brass bolster to the hand forged neck of the knife is perfect what just magnifies the difference between the perfectly finished handle and the hand forged finish of the blade. It sits very well in hand and feels best with pinch grip. It is also long enough - I can hardly imagine that someone could find it too small or short.

Choil, spine & bolster:

The choil (as well as the spine) are semi-rounded and very comfortable. The rounding was mostly made with hammer, so you do not get shiny polished area that would not fit so nicely with the finish of the blade.

Not to forget the sheath - it is a simple, but elegant one made from a very thick leather. The knife fits snugly and actually some force is needed to push the last 1-2 cm of the draw, so the sheath sits securely on the blade and does not require any additional attachment system.

OK - that is it for now. In the mean time the knife has made it first cuts, but that is to be reported in the second part.