Kippington

A small green parrot

I think some of you guys might find this interesting.

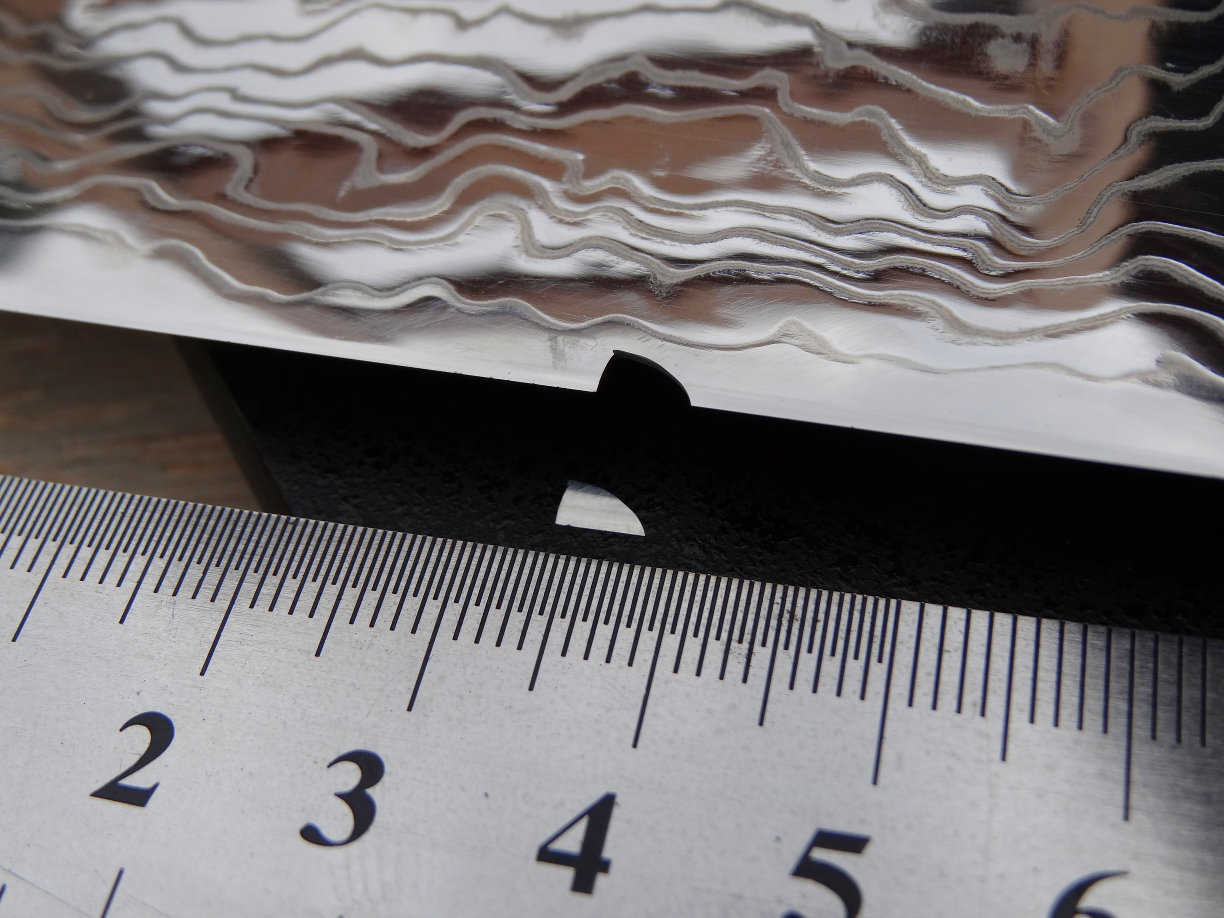

So at work yesterday I was cutting a big wedge of Parmesan cheese in half when I hear a *tink* sound, aaaannnnddddd...

(mildly interesting note: you can see micro and macro chipping in this image)

Ohhhh man

The initial damage to it actually goes a few months back - I received the knife on my birthday and consequently cracked in the blade on the first day due to playing with my new toy while drunk (I'm sure I am not the only person that does that sort of thing on this forum haha!)

The initial damage to the knife was the part of the chip that goes straight up, the curved part of the chip-out is where the lateral force pulled a good chunk out a few months later.

The knife is a Sukenari ZDP-189 Wa Gyuto 270mm at 66-67 HRC. The high hardness of this steel is gonna piss me off now that I gotta take a rather large bit of metal off the knife to remove the chip. I'll try to document my repair progress and post it here if anyone is interested.

Also, before I start repairs, I would happily oblige if anyone has a request for me to test the knife against something they think could potentially damage the edge. I have two of these ZDP-189 knives and they perform very well, so I'd be more then happy to run tests on the edge for you guys so that this thread doesn't give the wrong impression that the steel is too chippy or brittle.

Let me know!

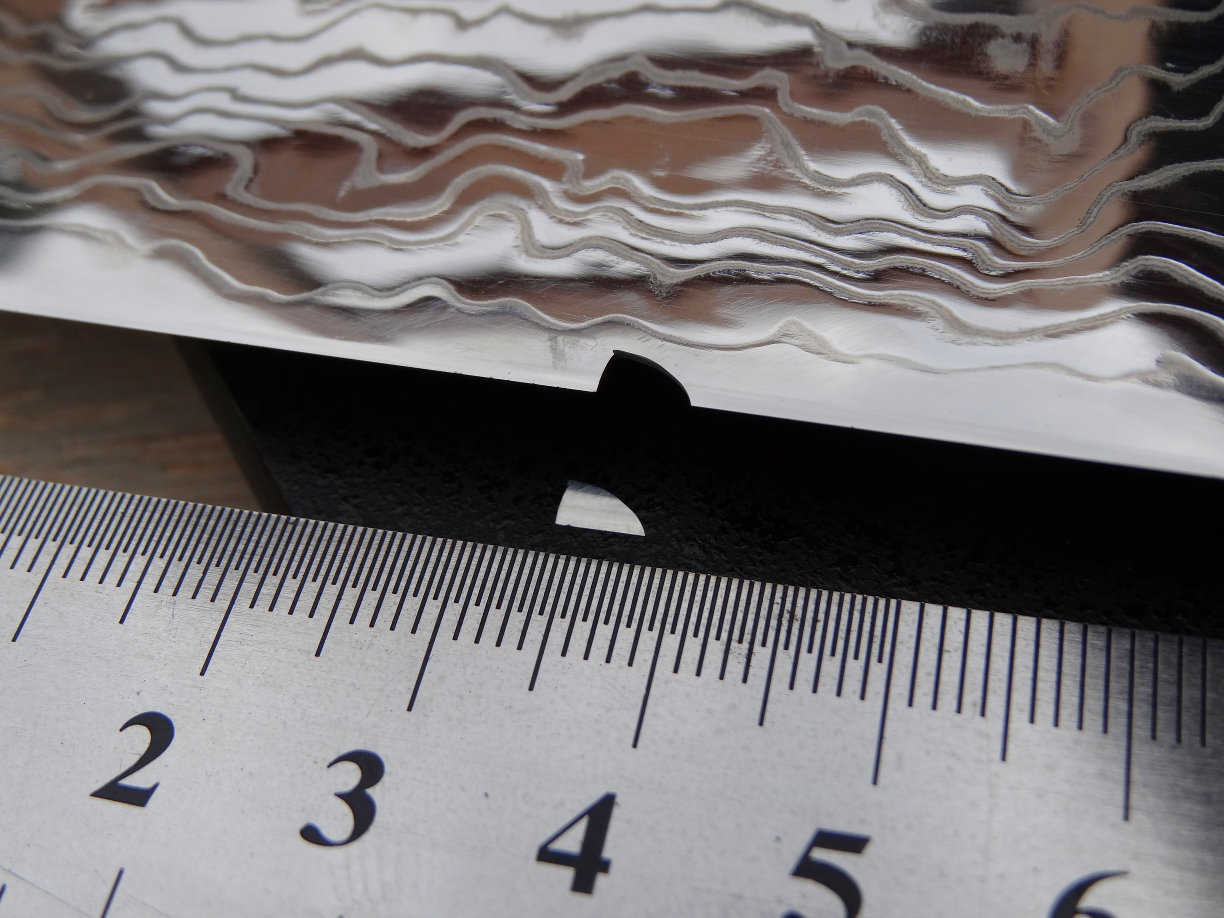

So at work yesterday I was cutting a big wedge of Parmesan cheese in half when I hear a *tink* sound, aaaannnnddddd...

(mildly interesting note: you can see micro and macro chipping in this image)

Ohhhh man

The initial damage to it actually goes a few months back - I received the knife on my birthday and consequently cracked in the blade on the first day due to playing with my new toy while drunk (I'm sure I am not the only person that does that sort of thing on this forum haha!)

The initial damage to the knife was the part of the chip that goes straight up, the curved part of the chip-out is where the lateral force pulled a good chunk out a few months later.

The knife is a Sukenari ZDP-189 Wa Gyuto 270mm at 66-67 HRC. The high hardness of this steel is gonna piss me off now that I gotta take a rather large bit of metal off the knife to remove the chip. I'll try to document my repair progress and post it here if anyone is interested.

Also, before I start repairs, I would happily oblige if anyone has a request for me to test the knife against something they think could potentially damage the edge. I have two of these ZDP-189 knives and they perform very well, so I'd be more then happy to run tests on the edge for you guys so that this thread doesn't give the wrong impression that the steel is too chippy or brittle.

Let me know!