Seth0941

Active Member

- Joined

- Mar 7, 2015

- Messages

- 29

- Reaction score

- 0

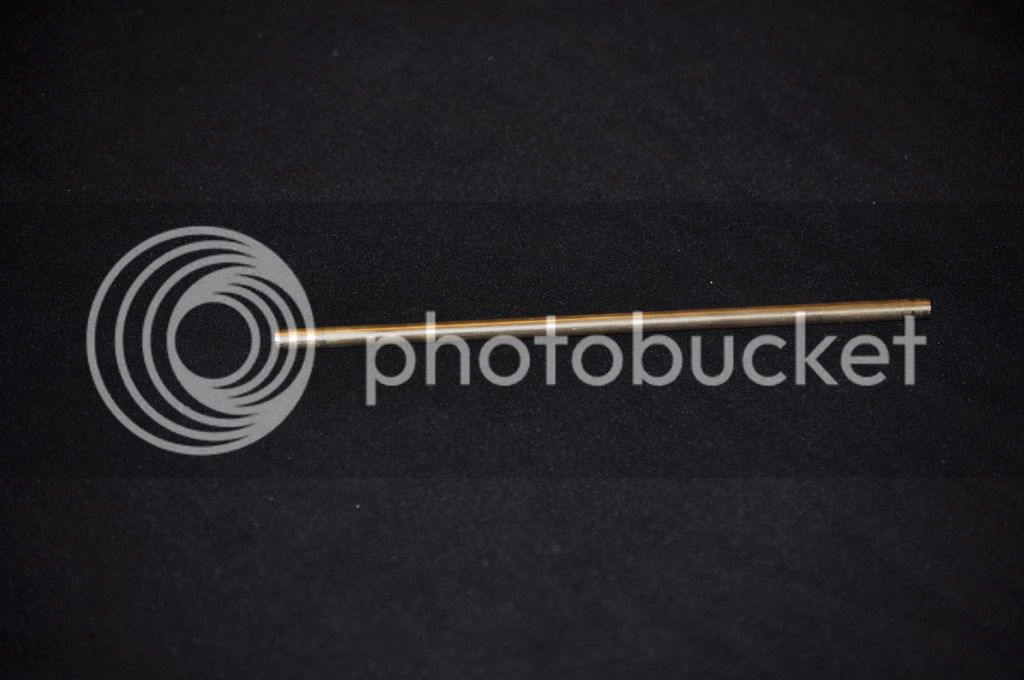

Okay, so I just got a "blank" off of the "bay" to practice making handles on. It was cheap and kinda cool looking (to me anyway) and I will probably give it away when I am done. I also ordered some scales too (see photos below). Anyone have any advice? I am going to use the push together style rivets (mostly because I have about 20 sets sitting here).