I'm kind of new to the world of Japanese knives, and thought I could help out some other new users with this thread.

First, a little backstory. I researched the daylights out of knives and finally decided to call Japanese Knife Imports for advice. Budget was not a big problem for me, anything within reason seemed affordable. After speaking to me a little, Jon told me I wasn't experienced enough to buy a high end knife, and steered me towards an Uraku 240 gyuto. I got the knife, it was okay but it wasn't brilliant. Didn't handle carrots and root vegetables terribly well. I bought a Takamura Migaki 210 as a point of comparison, that was much more what I had in mind but I'm not particularly enamored with that knife as an all a rounder. It seems a bit small and fragile to me. Good for dicing onions, though.

I also spent more for stones than I did for any one knife (actually, I may have spent more than for any two knives!). I bought a Gesshin 400, 2000, 6000 set up and had an old king 240/1000 combo. I also just bought a diamond flattening plate. In retrospect, spending the money on a complete set of stones early on was the smartest move I have made.

I finally decided that I'd try to thin the Uraku to see if I could get it to the point I wanted it. I've looked at a bunch of threads and videos about thinning but I was still pretty confused about the process. All you ever tend to see is what the finished product looks like. When I looked at my blade, I didn't know where I should take the steel away from.

So I took a picture of the choil and sent it in an email to Jon and asked him what to do. I've looked at these choil shots all along, and never realized what a powerful tool they could be to understand the geometry of your knife. I highly recommend getting a little spring clamp and shooting right down the handle to see what the cross sectional geometry of your knife really is.

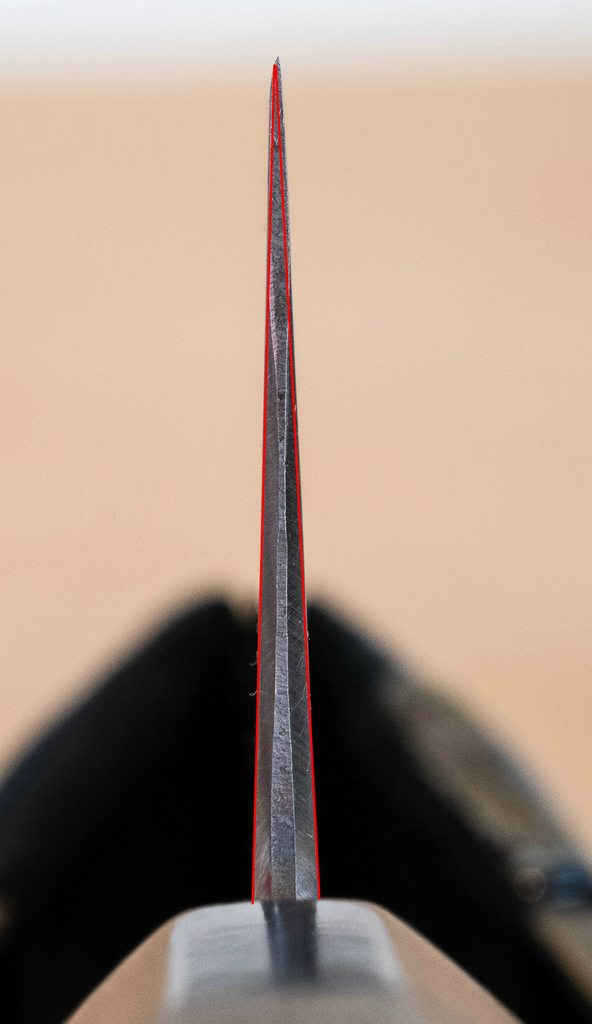

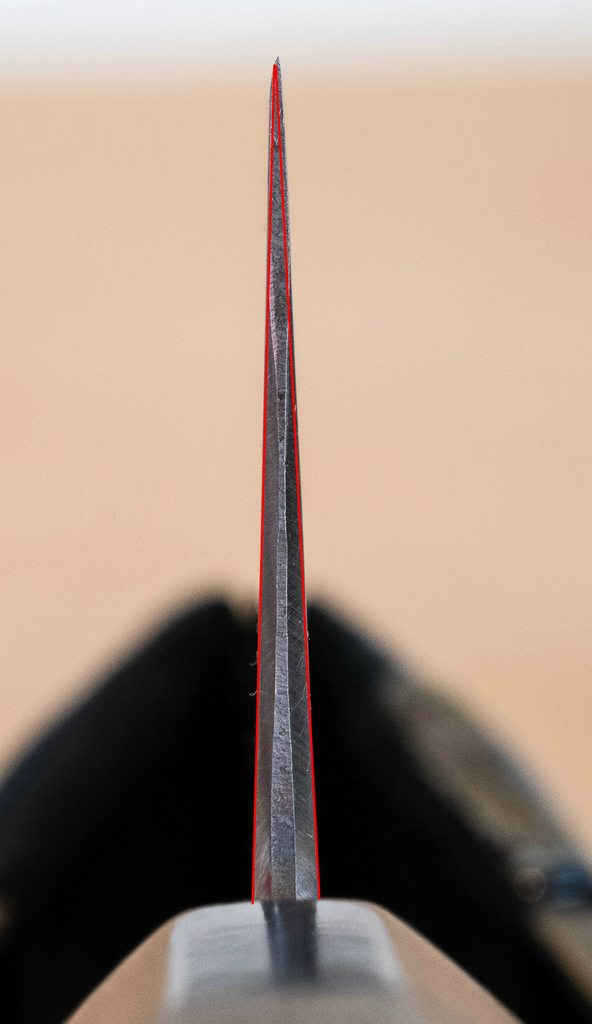

Original:

Jon talked to me on the phone for a bit and said he'd mark up my image to show me what I was aiming for. He told me to start on the King 240 and then go to the 400. Here's his markup:

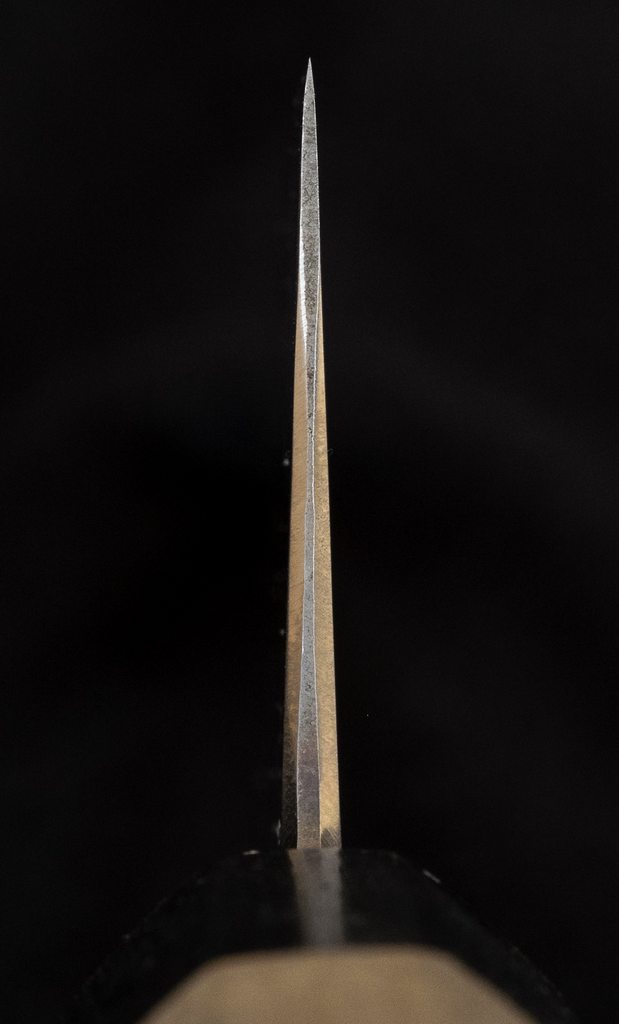

I read over and over that it's easier to take steel off a blade than to put it back on so I thought I'd do this in a couple of phases. Here's phase one, which was a lot better but still not brilliant:

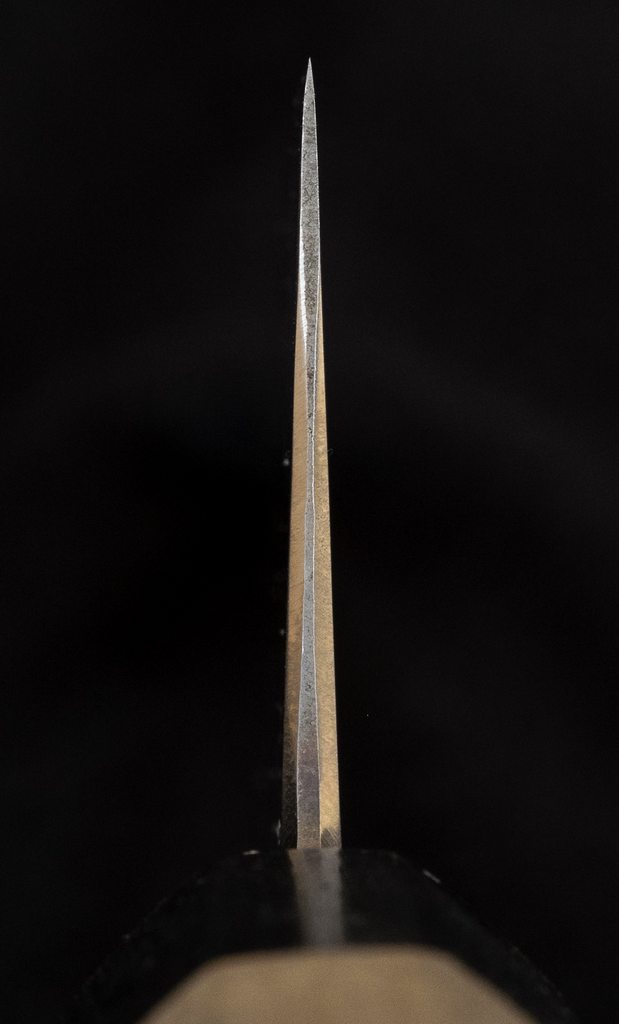

Mailed it off to Jon, he said he'd keep going. Here's phase two:

Eureka! This thing started flying through food. I got so excited after I cut one carrot, I put a leash on the dog, walked down to the greengrocer and bought a bag of vegetables. (I also upped my photo game for this one!).

I'm not sure if I'm done or if there's a phase three around the corner, but this has been a really fun and informative process, and I feel I now have a knife that I have control over, both on the board and on the stones as a result.

Anyway, my take-away from all this is pretty simple:

1-Start with a starter knife. Good advice, repeated often, I'm glad I followed it. I would have learned NOTHING if my first knife was a Gesshin Ginga or the Takamura.

2-Spend money on stones over knives. A decent knife with great geometry and a good edge is a really good cutter. An expensive knife that gets dull is a dull knife.

3-Figure out a way to visualize your edge. I found the process of taking photos invaluable to understand what I'm doing.

4-A vendor who can help is worth whatever the difference in initial cost might be.

Hope you find this helpful

Rick

First, a little backstory. I researched the daylights out of knives and finally decided to call Japanese Knife Imports for advice. Budget was not a big problem for me, anything within reason seemed affordable. After speaking to me a little, Jon told me I wasn't experienced enough to buy a high end knife, and steered me towards an Uraku 240 gyuto. I got the knife, it was okay but it wasn't brilliant. Didn't handle carrots and root vegetables terribly well. I bought a Takamura Migaki 210 as a point of comparison, that was much more what I had in mind but I'm not particularly enamored with that knife as an all a rounder. It seems a bit small and fragile to me. Good for dicing onions, though.

I also spent more for stones than I did for any one knife (actually, I may have spent more than for any two knives!). I bought a Gesshin 400, 2000, 6000 set up and had an old king 240/1000 combo. I also just bought a diamond flattening plate. In retrospect, spending the money on a complete set of stones early on was the smartest move I have made.

I finally decided that I'd try to thin the Uraku to see if I could get it to the point I wanted it. I've looked at a bunch of threads and videos about thinning but I was still pretty confused about the process. All you ever tend to see is what the finished product looks like. When I looked at my blade, I didn't know where I should take the steel away from.

So I took a picture of the choil and sent it in an email to Jon and asked him what to do. I've looked at these choil shots all along, and never realized what a powerful tool they could be to understand the geometry of your knife. I highly recommend getting a little spring clamp and shooting right down the handle to see what the cross sectional geometry of your knife really is.

Original:

Jon talked to me on the phone for a bit and said he'd mark up my image to show me what I was aiming for. He told me to start on the King 240 and then go to the 400. Here's his markup:

I read over and over that it's easier to take steel off a blade than to put it back on so I thought I'd do this in a couple of phases. Here's phase one, which was a lot better but still not brilliant:

Mailed it off to Jon, he said he'd keep going. Here's phase two:

Eureka! This thing started flying through food. I got so excited after I cut one carrot, I put a leash on the dog, walked down to the greengrocer and bought a bag of vegetables. (I also upped my photo game for this one!).

I'm not sure if I'm done or if there's a phase three around the corner, but this has been a really fun and informative process, and I feel I now have a knife that I have control over, both on the board and on the stones as a result.

Anyway, my take-away from all this is pretty simple:

1-Start with a starter knife. Good advice, repeated often, I'm glad I followed it. I would have learned NOTHING if my first knife was a Gesshin Ginga or the Takamura.

2-Spend money on stones over knives. A decent knife with great geometry and a good edge is a really good cutter. An expensive knife that gets dull is a dull knife.

3-Figure out a way to visualize your edge. I found the process of taking photos invaluable to understand what I'm doing.

4-A vendor who can help is worth whatever the difference in initial cost might be.

Hope you find this helpful

Rick