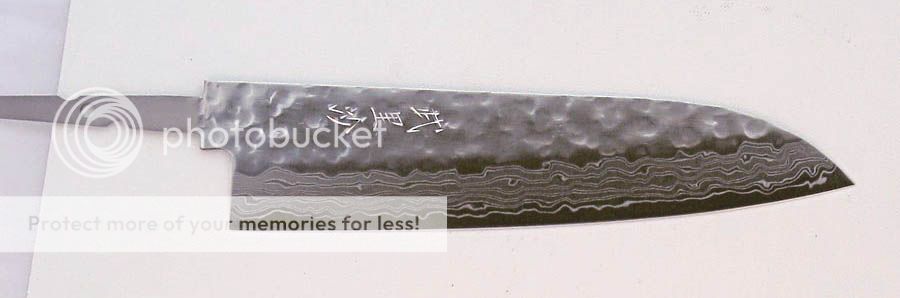

Is there anybody who knows this knife blank?

Its sold by Brisa (https://www.brisa.fi/portal/index.p...Mod=product_info&cPath=94_51&products_id=3070 ). I also found it in two other webshops, but everywhere it is nameless.

Its sold by Brisa (https://www.brisa.fi/portal/index.p...Mod=product_info&cPath=94_51&products_id=3070 ). I also found it in two other webshops, but everywhere it is nameless.