WillC

Senior Member

- Joined

- Jul 9, 2011

- Messages

- 2,142

- Reaction score

- 2

Ah well yes, I may have liberated a tiny smidge of iron from the cliffs whilst on holiday. But in my defence I'm pretty sure the laws relating to keeping things on coastal areas relate to items washed up, not tossed off the cliff, and I don't think in the grand scheme of things anyone will miss this smidge amongst literally tons of pre WW1 french artillery barrels tossed into the sea after Germany's occupation of the small rock off the french coastline.

Iron is deeply fascinating material and with some knowledge of working various grades of this material from the good bad to the downright Ugly I have gained a proper appreciation of the joy of wrought iron at its very best grade. The finest grades are rolled welded and rerolled many times over to achieve a very fine structural grade. I fully expect it to reveal the finest strands and "clouds" upon polish and light etch.

A kind of misinterpretation (or catch 22, depending on which way you look at it), of iron in cutlery, is that it will rust, reality and practice is the opposite to this. It is remarkably resistant to rust, iron has a huge list of trace elements which allow the material to form a protective coating or patina slowing further corrosion to an incredibly slow rate even in the harshest environments, for example exposed to both salt and oxygen. The finest and most refined grades of iron was known as "black iron" Rolled and rerolled many times it must have been hugely inefficient to produce and used structurally on ship hulls, artillery, bridges, it earned the nick name due to the apparent black skin formed from content chemical exposure, seemingly protecting itself from oxidation. I suppose this is where the annoyance comes in cutlery, as it will patina, it must patina by its very nature, this can of course be an annoyance to those who have lovingly brought out the beautiful natural clouds in the fine stands by polishing with natural stones. Of course all the time you use the material it will be working against you with acids in foods and oxygen to form a protective layer once more. Its up to the user how to work with this anomaly, perhaps it works best on traditional wide bevel knives, where you maintain the wide bevel and enjoy the clouds and activity between iron and core, allowing the rest of the knife to form patina. And if you enjoy polishing too much, well it could be perfect for you in that respect.

Either way you can be safe in the knowledge that if you should happen to misplace your knife by the seaside for a hundred years or so, your iron cladding will be there long after the steel core has corroded and retreated into its iron jacket.

Good iron is of course a makers dream, having welding temperatures lower than mild steel, allowing wonderful clean open welding with minimal carbon loss of the core material.

So there it is enough nonsense from.........to the iron...

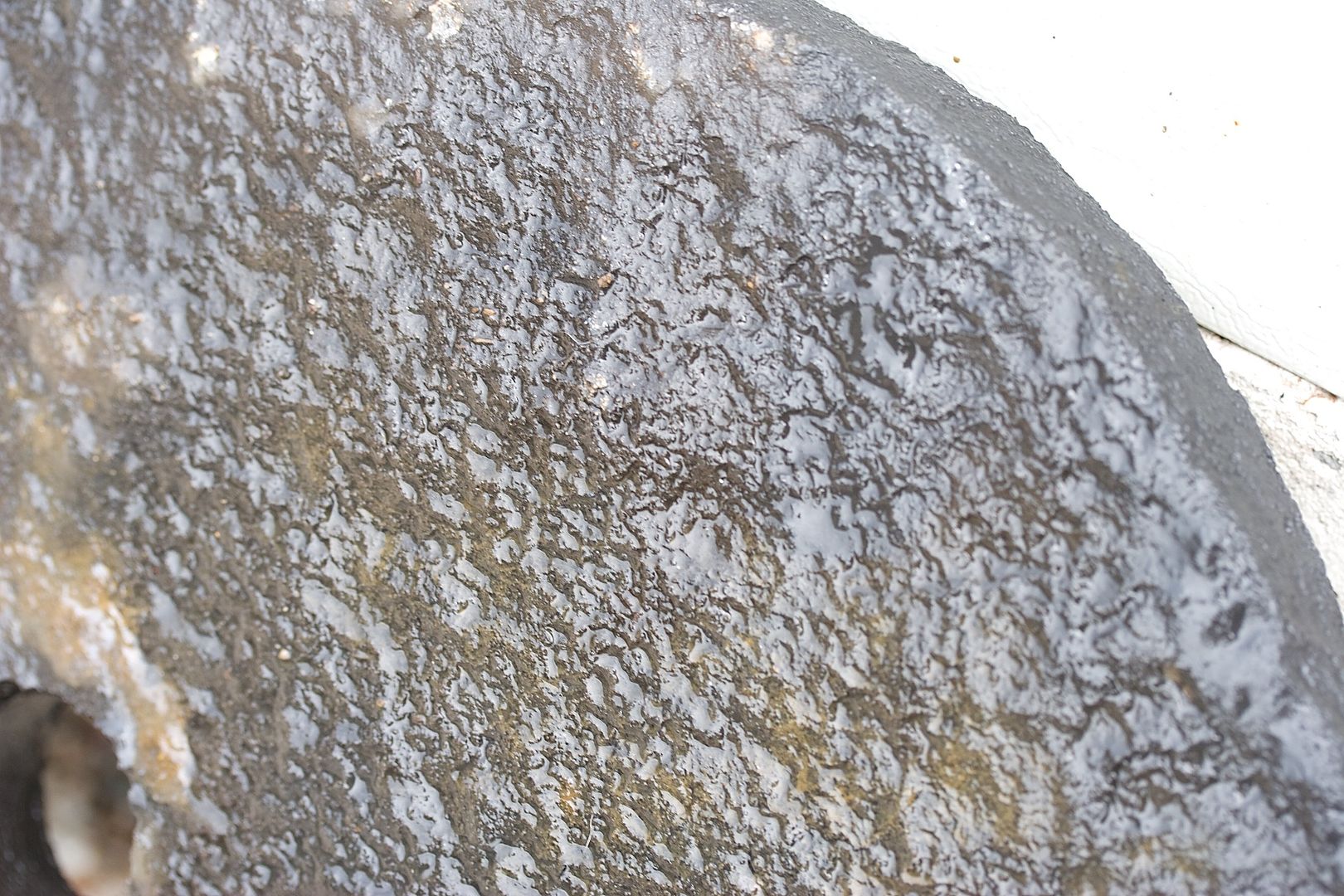

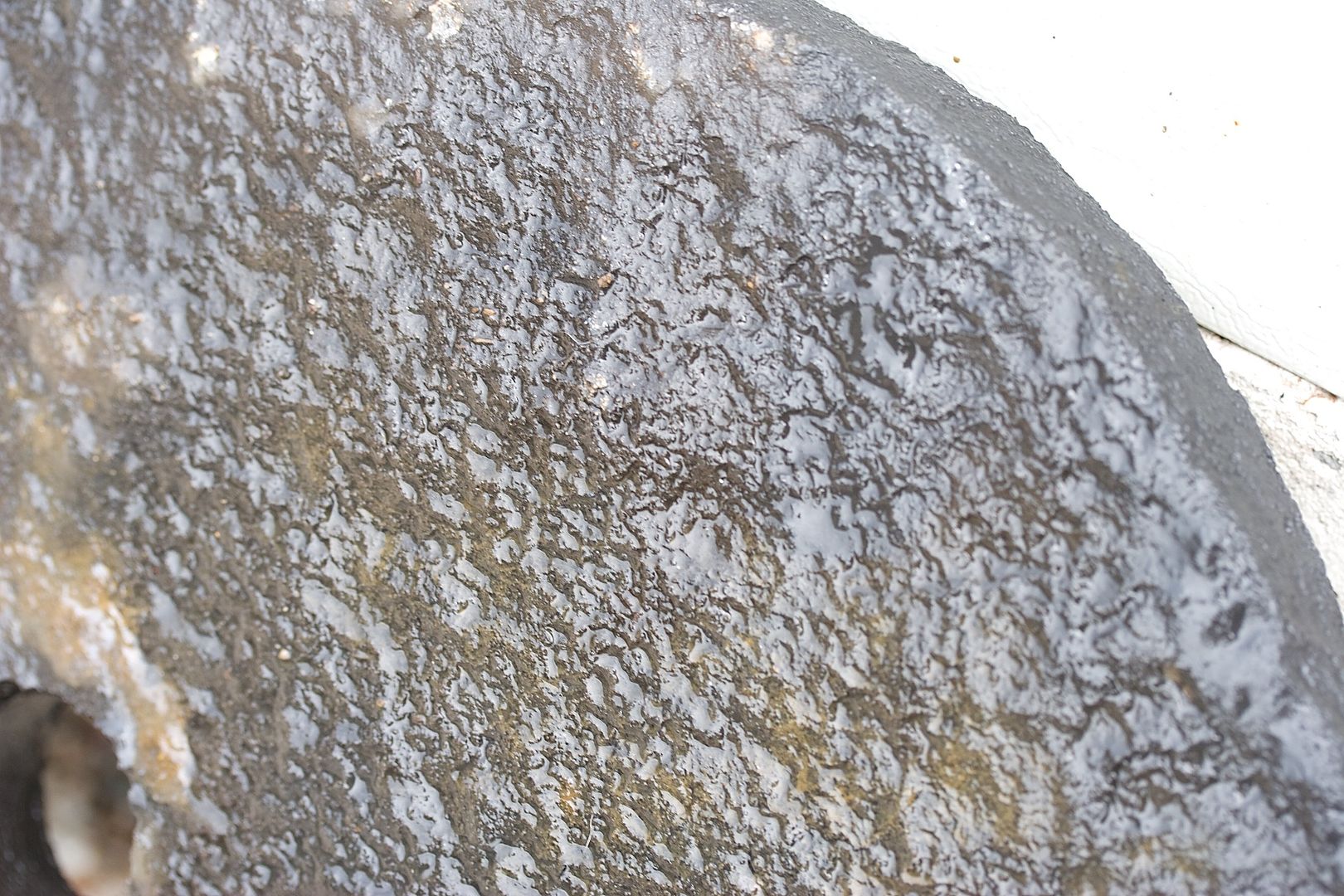

Here is the ickle piece I rescued and it came home with me on the back of my Motorcycle.

At this point I have pickled the piece in Hydrochloric overnight, which other than removing the barnacles appears to have had very little effect on the iron, other than making it go very black!

You can still see a misplaced pilot hole, testament to how little this material has corroded since enlisting in the French artillery prior to WW1.

Just under a 20lb chunk.

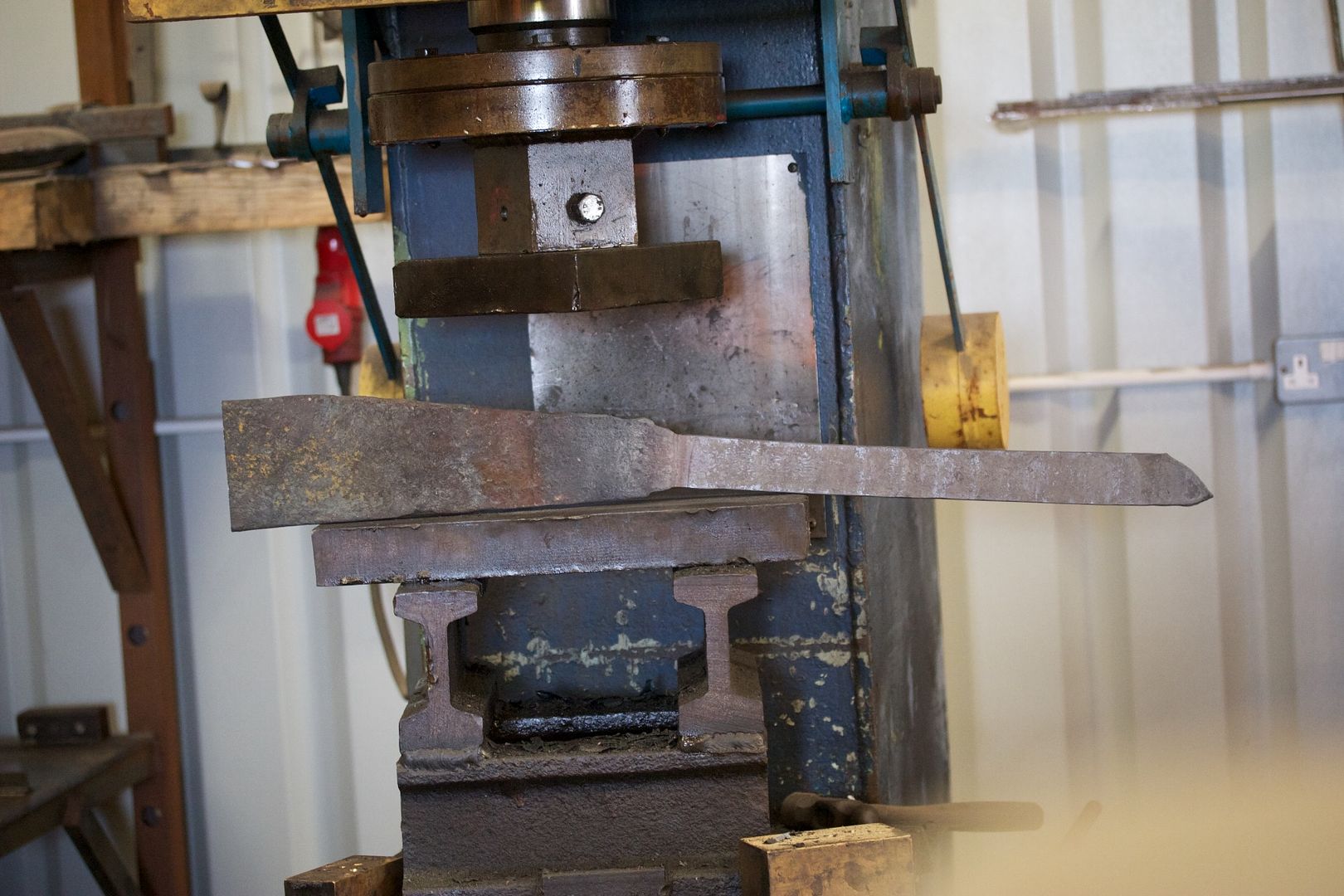

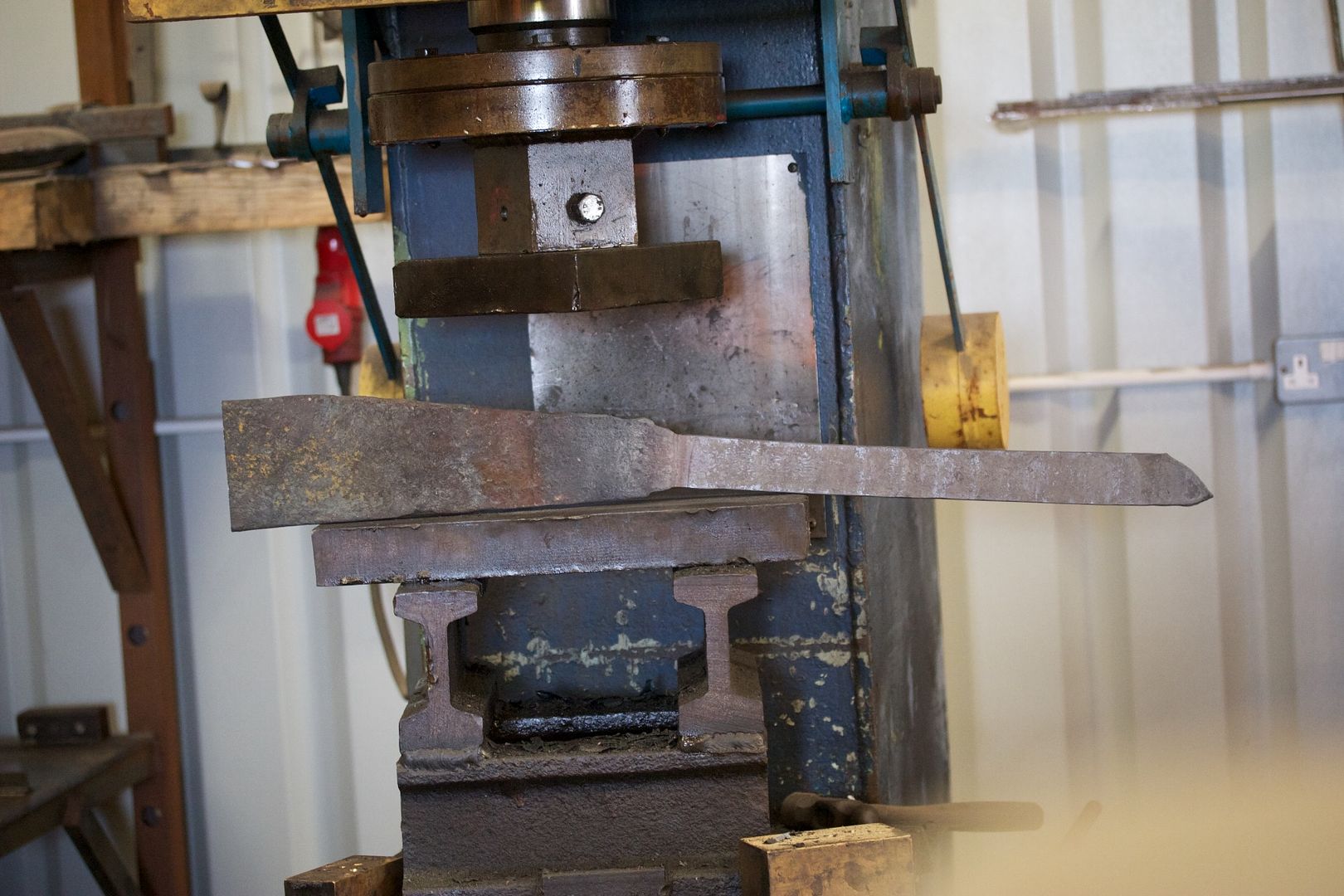

Plan is to straighten the material to keep the grain naturally aligned, and forge into a couple of bars, one from the section without holes for blade stock and then reweld the piece with holes and forge into a chunkier bar for some bolster stock.

So after a couple of hours forging I have some great stock for san mai and single bevel work, and what a pleasure it is to work this amazing stuff:big grin:

Thanks all, hope you enjoy my little article and like me look forward to seeing the work it inspires.

Iron is deeply fascinating material and with some knowledge of working various grades of this material from the good bad to the downright Ugly I have gained a proper appreciation of the joy of wrought iron at its very best grade. The finest grades are rolled welded and rerolled many times over to achieve a very fine structural grade. I fully expect it to reveal the finest strands and "clouds" upon polish and light etch.

A kind of misinterpretation (or catch 22, depending on which way you look at it), of iron in cutlery, is that it will rust, reality and practice is the opposite to this. It is remarkably resistant to rust, iron has a huge list of trace elements which allow the material to form a protective coating or patina slowing further corrosion to an incredibly slow rate even in the harshest environments, for example exposed to both salt and oxygen. The finest and most refined grades of iron was known as "black iron" Rolled and rerolled many times it must have been hugely inefficient to produce and used structurally on ship hulls, artillery, bridges, it earned the nick name due to the apparent black skin formed from content chemical exposure, seemingly protecting itself from oxidation. I suppose this is where the annoyance comes in cutlery, as it will patina, it must patina by its very nature, this can of course be an annoyance to those who have lovingly brought out the beautiful natural clouds in the fine stands by polishing with natural stones. Of course all the time you use the material it will be working against you with acids in foods and oxygen to form a protective layer once more. Its up to the user how to work with this anomaly, perhaps it works best on traditional wide bevel knives, where you maintain the wide bevel and enjoy the clouds and activity between iron and core, allowing the rest of the knife to form patina. And if you enjoy polishing too much, well it could be perfect for you in that respect.

Either way you can be safe in the knowledge that if you should happen to misplace your knife by the seaside for a hundred years or so, your iron cladding will be there long after the steel core has corroded and retreated into its iron jacket.

Good iron is of course a makers dream, having welding temperatures lower than mild steel, allowing wonderful clean open welding with minimal carbon loss of the core material.

So there it is enough nonsense from.........to the iron...

Here is the ickle piece I rescued and it came home with me on the back of my Motorcycle.

At this point I have pickled the piece in Hydrochloric overnight, which other than removing the barnacles appears to have had very little effect on the iron, other than making it go very black!

You can still see a misplaced pilot hole, testament to how little this material has corroded since enlisting in the French artillery prior to WW1.

Just under a 20lb chunk.

Plan is to straighten the material to keep the grain naturally aligned, and forge into a couple of bars, one from the section without holes for blade stock and then reweld the piece with holes and forge into a chunkier bar for some bolster stock.

So after a couple of hours forging I have some great stock for san mai and single bevel work, and what a pleasure it is to work this amazing stuff:big grin:

Thanks all, hope you enjoy my little article and like me look forward to seeing the work it inspires.