Culverin

Well-Known Member

- Joined

- Sep 15, 2013

- Messages

- 70

- Reaction score

- 1

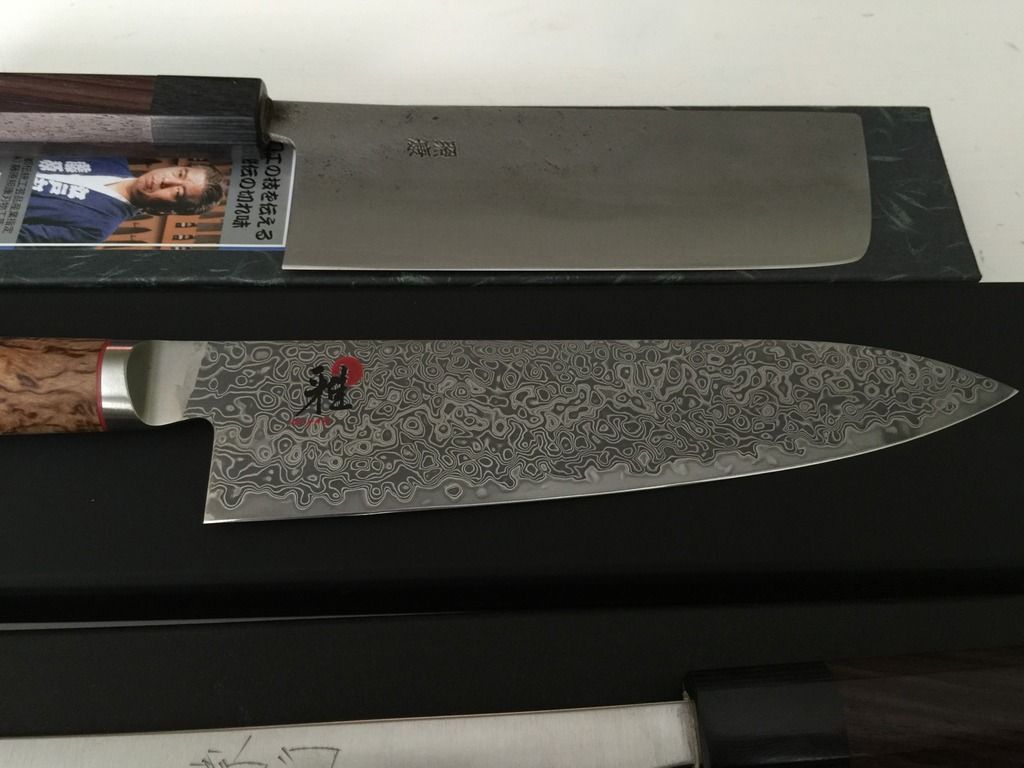

Was browsing through BST and saw Livlif's etched Miyabi.

Wow. Such an improvement over stock.

http://www.kitchenknifeforums.com/showthread.php/23288-Cool-Knives-For-Sale!-Fujiwara-Kotetsu-Miyabi

The muted damascus pattern was on the deciding factors against me picking up that Miyabi 600MCD I was asking about previously.

I didn't know this could be done.

I always assumed the dark colors on the Hattori KD and the Tanaka Ironwood blades were from the metals used.

That got me thinking, how come parts of the knife get dark, and other stay light?

Ran a search and came across Dave's 2 threads:

http://www.kitchenknifeforums.com/showthread.php/11803-Gallery-Hiromoto-AS-Full-Spa-Treatment

http://www.kitchenknifeforums.com/showthread.php/6474-Damascus-Knives-amp-Re-Etchng

From my recollection, the damascus patterns from claddings a secondary stainless with a higher nickel concentration?

So the nickel darkens?

And from the Hiromoto thread, it looks like the carbon steel darkens?

Can this be done with any blade to make it super dark?

Will this work on an Takamura Hana?

Wow. Such an improvement over stock.

http://www.kitchenknifeforums.com/showthread.php/23288-Cool-Knives-For-Sale!-Fujiwara-Kotetsu-Miyabi

The muted damascus pattern was on the deciding factors against me picking up that Miyabi 600MCD I was asking about previously.

I didn't know this could be done.

I always assumed the dark colors on the Hattori KD and the Tanaka Ironwood blades were from the metals used.

That got me thinking, how come parts of the knife get dark, and other stay light?

Ran a search and came across Dave's 2 threads:

http://www.kitchenknifeforums.com/showthread.php/11803-Gallery-Hiromoto-AS-Full-Spa-Treatment

http://www.kitchenknifeforums.com/showthread.php/6474-Damascus-Knives-amp-Re-Etchng

From my recollection, the damascus patterns from claddings a secondary stainless with a higher nickel concentration?

So the nickel darkens?

And from the Hiromoto thread, it looks like the carbon steel darkens?

Can this be done with any blade to make it super dark?

Will this work on an Takamura Hana?