stereo.pete

Senior Member

- Joined

- Mar 2, 2011

- Messages

- 2,398

- Reaction score

- 366

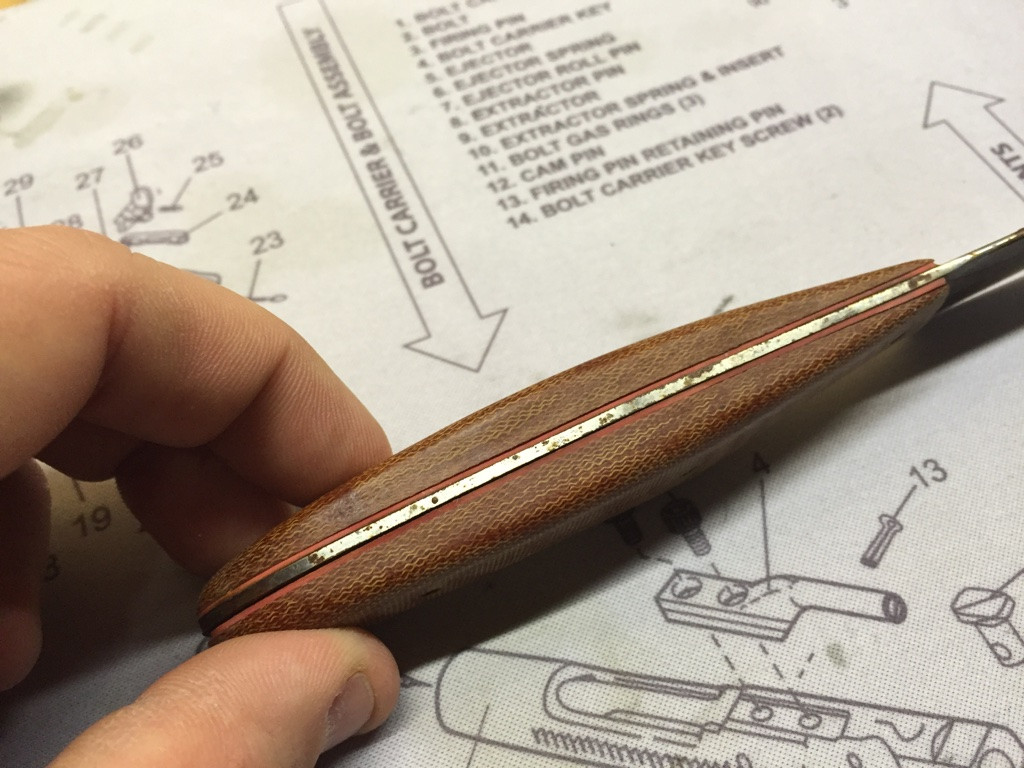

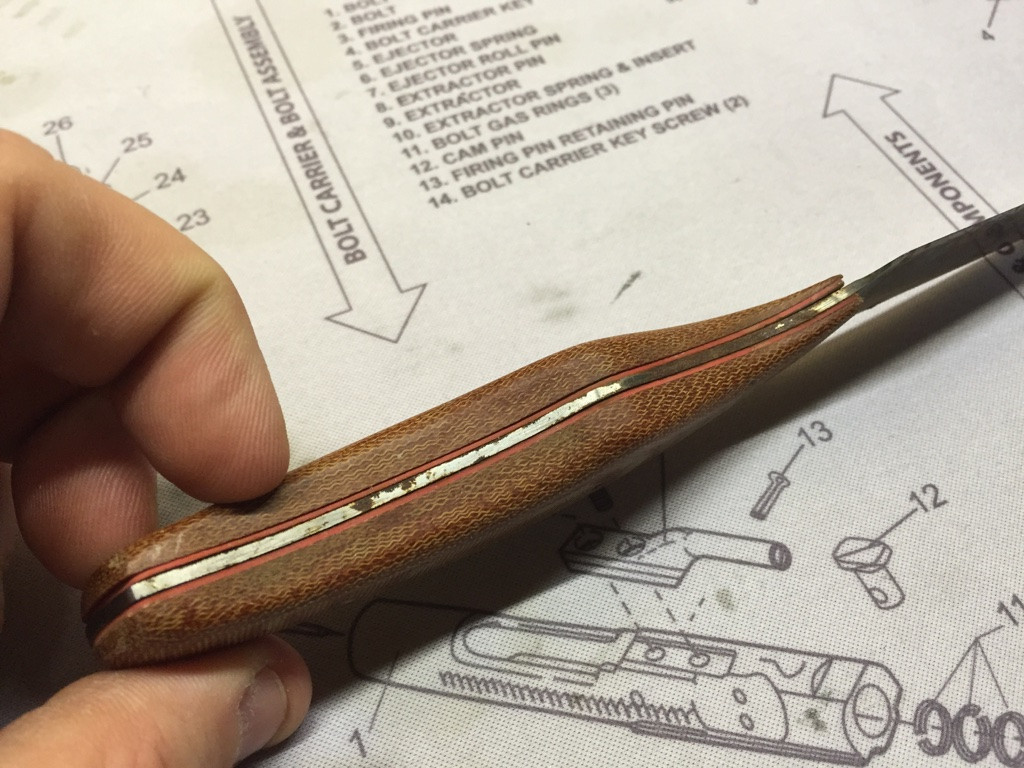

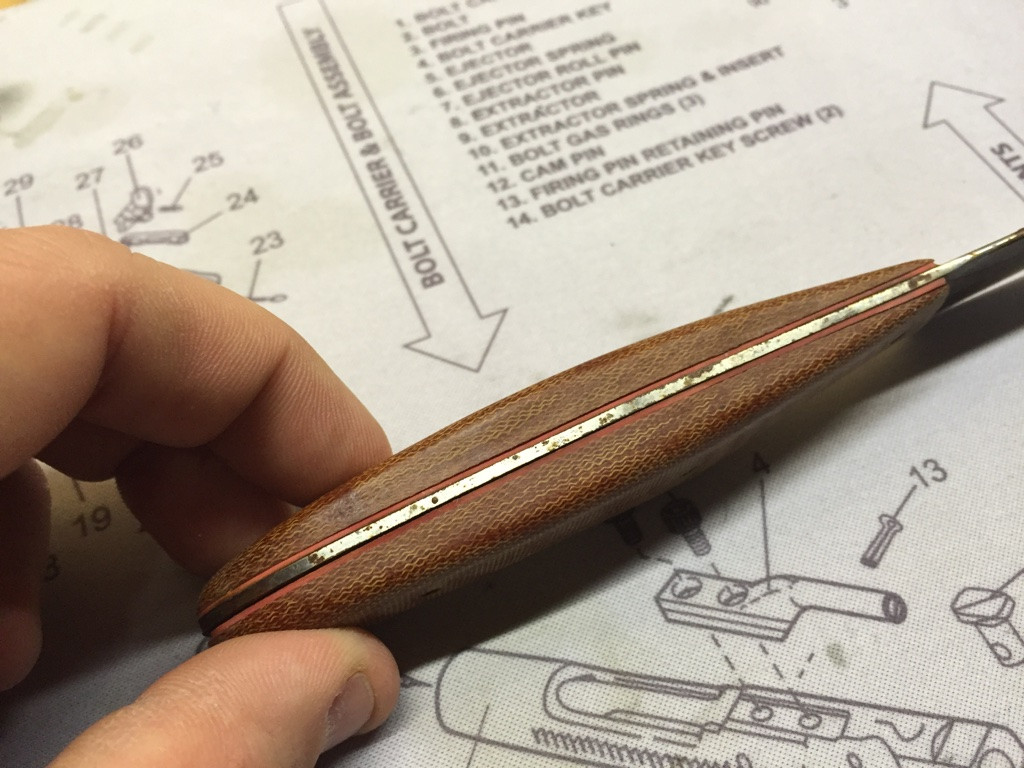

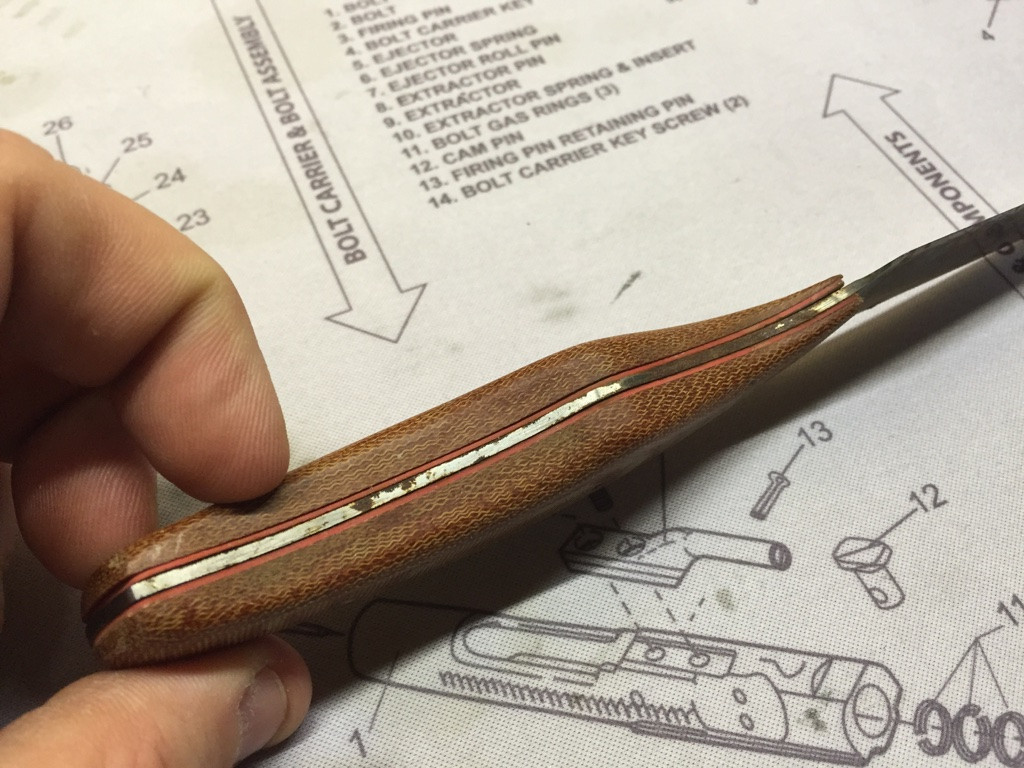

Well, I made this knife for my FIL for Christmas last year and he's enjoyed it quite a bit. In fact it's become his go to kitchen knife, but I knew it was only a matter of time before my MIL got her hands on it and did something goofy. Sure enough, about three weeks ago she thought she would be nice, and toss it in the dish washer. Well, let's just say O1 and paper liners do not react well to the chaotic environment held within a dish washer. The micarta had little to no damage except for some scratches.

Here she is after I removed the handle, I will post refinishing pics as I make progress. My goal is to have her ready again for service by Christmas.

Here she is after I removed the handle, I will post refinishing pics as I make progress. My goal is to have her ready again for service by Christmas.