Hi,

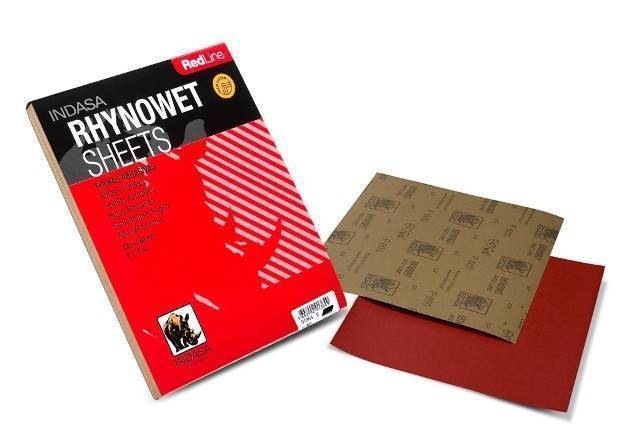

I have just spend 2 hours using sanding paper (on small wooden block as support) my first kitchen blade (monosteel O1 at 61 HRC). The blade was previously thinned (after HT) on Atoma 140 and scratches taken out with Bester 220. After little experimenting I proceeded with sanding paper in 120, 180, 240 grit (changing direction with every grit). It did not go fast, but I could see when all the previous scratches were removed. So far so good.

The problem was when I flipped the knife to sand the other side. I have used a piece of wood (which roughly shaped to follow the profile of the blade). While sanding - the loose grit from the sanding paper together with the WD40 I used as lubricant crawled under the blade, got between blade and the wood - and caused scratches (something I suspected could happen, but now I got experimental proof).

Q: What would be the best approach to avoid this happening again in the future?

thank you

I have just spend 2 hours using sanding paper (on small wooden block as support) my first kitchen blade (monosteel O1 at 61 HRC). The blade was previously thinned (after HT) on Atoma 140 and scratches taken out with Bester 220. After little experimenting I proceeded with sanding paper in 120, 180, 240 grit (changing direction with every grit). It did not go fast, but I could see when all the previous scratches were removed. So far so good.

The problem was when I flipped the knife to sand the other side. I have used a piece of wood (which roughly shaped to follow the profile of the blade). While sanding - the loose grit from the sanding paper together with the WD40 I used as lubricant crawled under the blade, got between blade and the wood - and caused scratches (something I suspected could happen, but now I got experimental proof).

Q: What would be the best approach to avoid this happening again in the future?

thank you