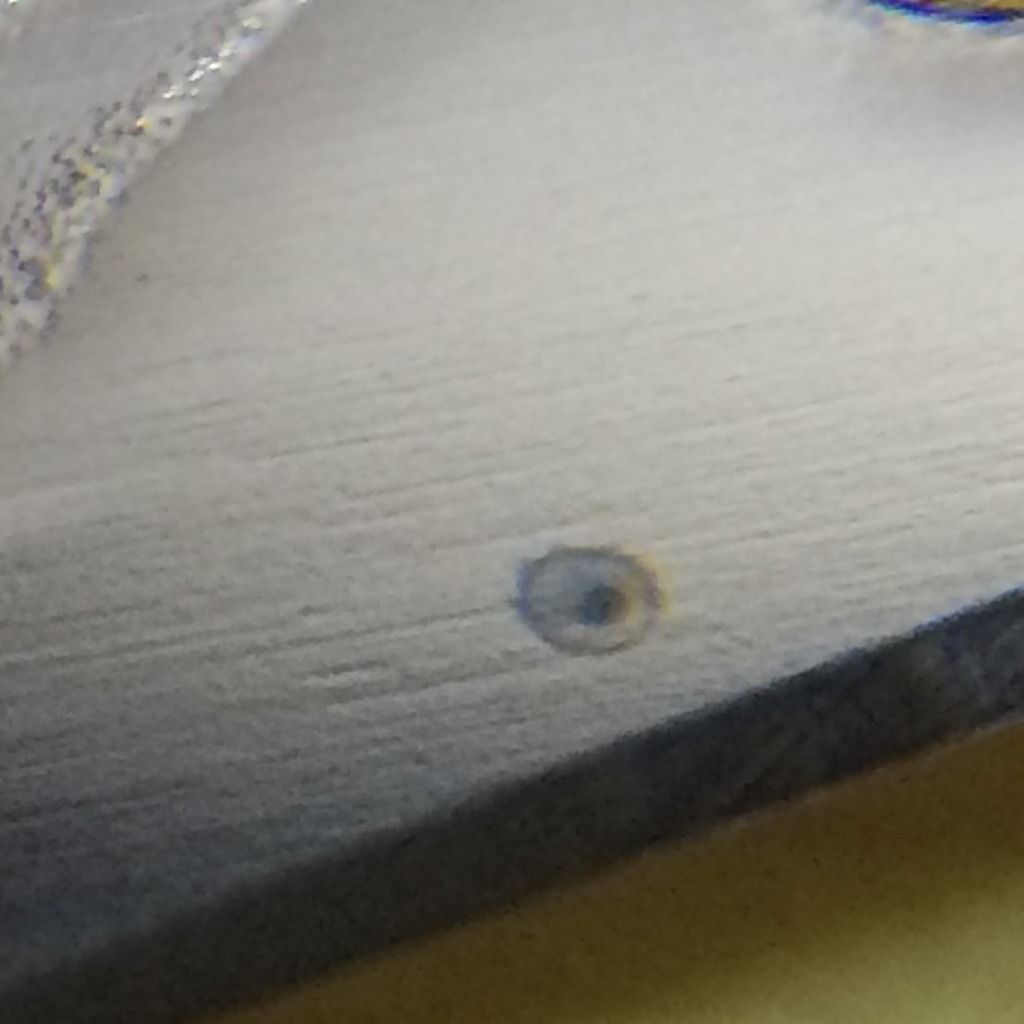

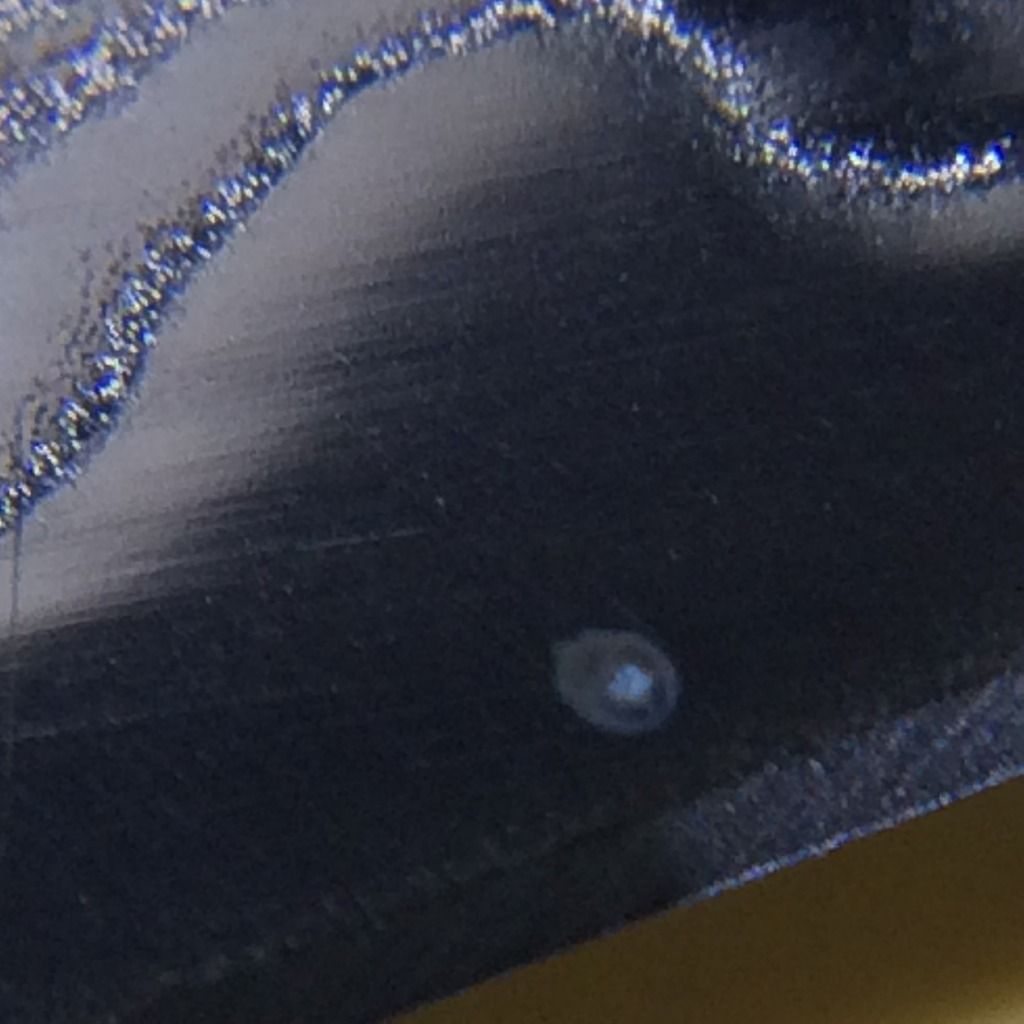

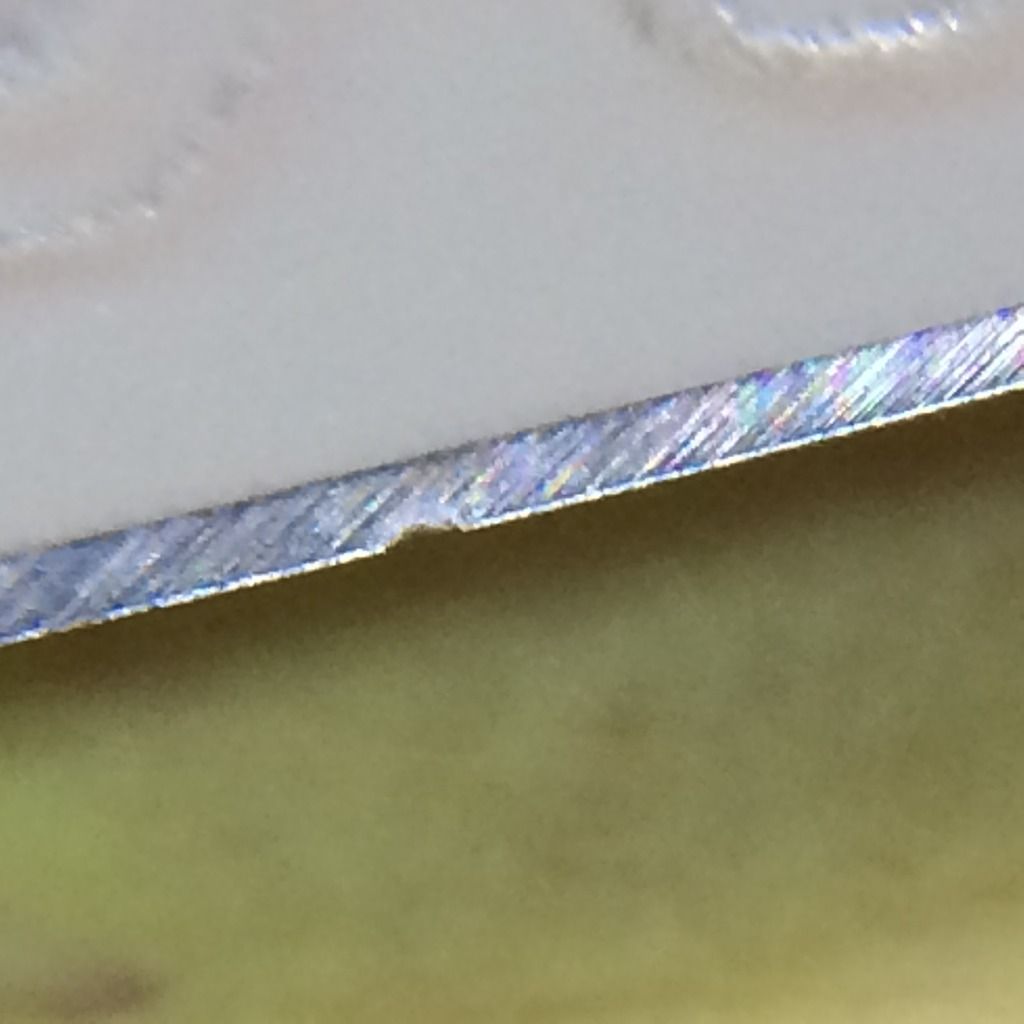

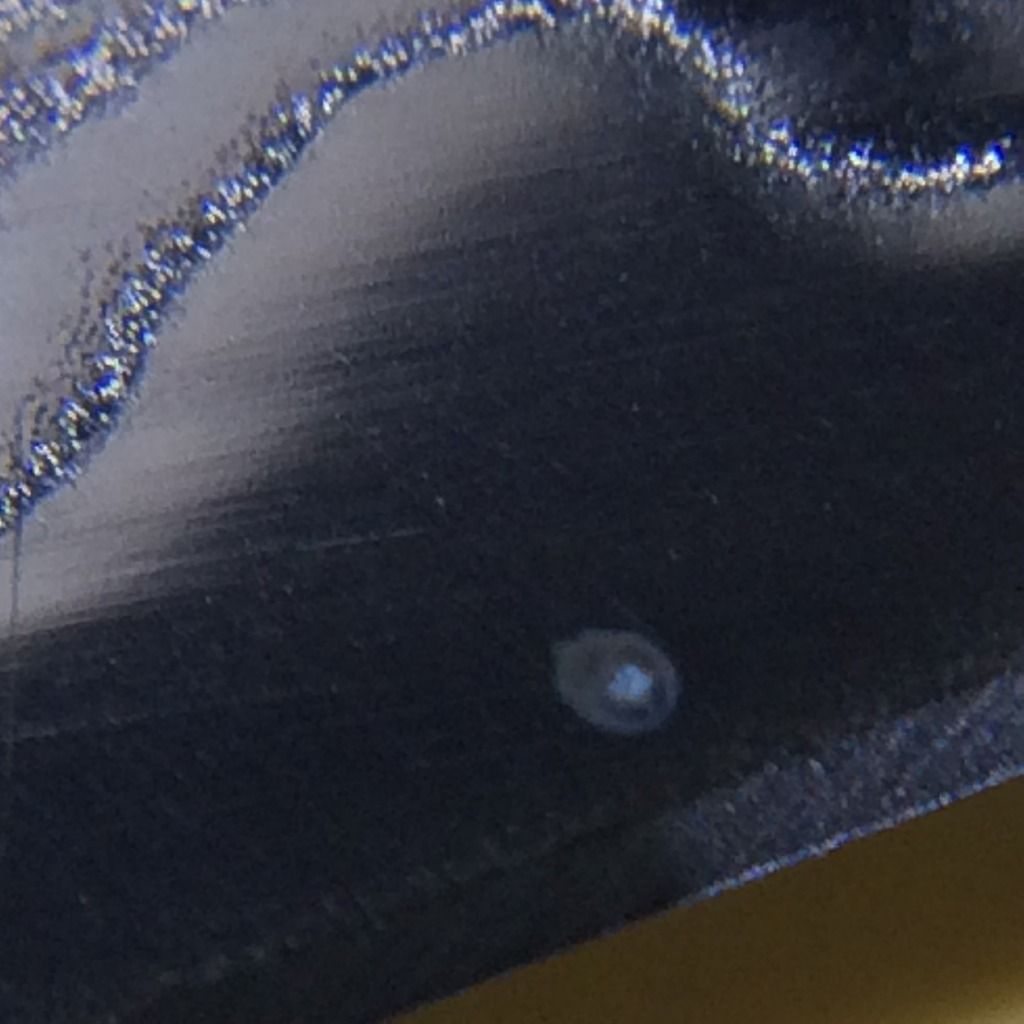

I was surprised (still am actually) to see that this happened given the high chromium content of ZDP-189. I had washed and rinsed the knife and probably had it resting on a towel for a few minuets while I washed a few other things prior to drying (I wash several things at a time for economy of motion, rather than wash/dry repeat).

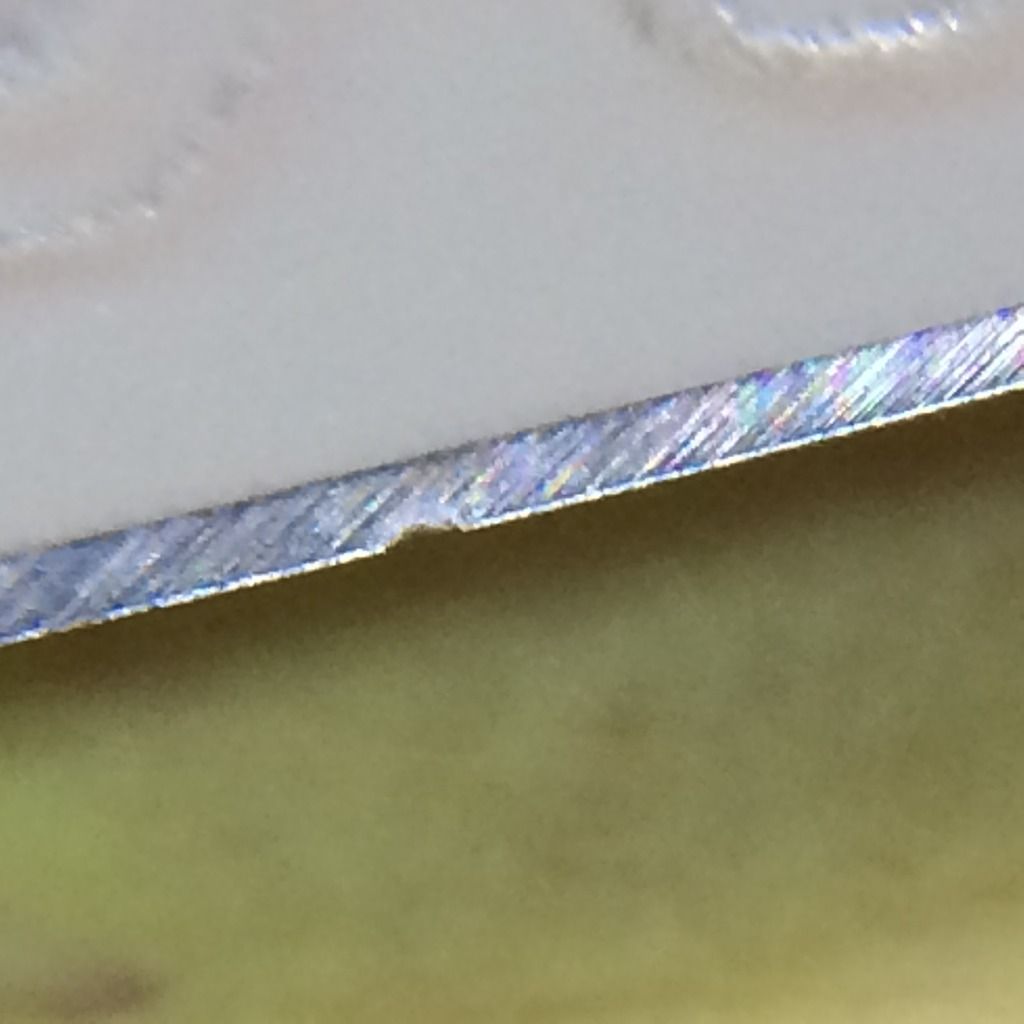

I've done this with R2 and even misono Carbon for way longer without issues, and with stuff other than tap water for rinsing. Ive left my cheap J.A. Henckels International knives in the sink overnight when I'm too lazy to wash them without problems (what are beater knives for?), and after this ZDP incident I even left my itinomonn wa butcher sitting for about 4 hours with chicken juice as a test and not a spot of rust to be seen pics or it didn't happen:

Anyone care to hazard a guess as to whether there may be metallurgical issues with this particular knife or if I should just not be so lazy and dry immediately?

I've done this with R2 and even misono Carbon for way longer without issues, and with stuff other than tap water for rinsing. Ive left my cheap J.A. Henckels International knives in the sink overnight when I'm too lazy to wash them without problems (what are beater knives for?), and after this ZDP incident I even left my itinomonn wa butcher sitting for about 4 hours with chicken juice as a test and not a spot of rust to be seen pics or it didn't happen:

Anyone care to hazard a guess as to whether there may be metallurgical issues with this particular knife or if I should just not be so lazy and dry immediately?