After some considerations I have decided to up my membership to Hobbyist Craftsman. It may be a little premature as I will need 2-3 months more to have anything for sale, but it also helps me to focus more on the results and also to put the word out that I mean it more seriously

My knifemaking activities so far are mostly concentrated on WA handled knifemaking and making WA handles for existing blades/knives. The only gyuto (that D2 beast that learned me a couple of lessons) is currently on long term loan to a chef in Prague and the feedback has been rather positive - experience like that not only gave me a boost in confidence and motivation, but also is partially responsible for me to join the Hobbyist Craftsman club as this will give me better chance to have my knives tested as the feedback from experienced users is for me crucial to further learn and improve.

I have also thinned and re-finish one Gesshin Hide 225 blue #1 gyuto (will soon appear on my blog) and learned a LOT of respect to guys like Jon who can do such a job in fraction of time.

For the near future I plan to continue focusing on WA handled knives and will leave wester handles for later.

I would also like to use this post to thank all those craftsmen from KKF than have been (and are) very helpful and supportive as their advices have often spared me running in the wrong direction or just missing the better/easier/more reliable way to do things.

I am really enjoying the process. I hope that I should soon have a proper 2x72" grinder that should allow me to improve and speed up many parts of the process. So stay tuned

This thread would be worthless without pictures, so here are a few (most of these have been posted around here) of the work I have done until today:

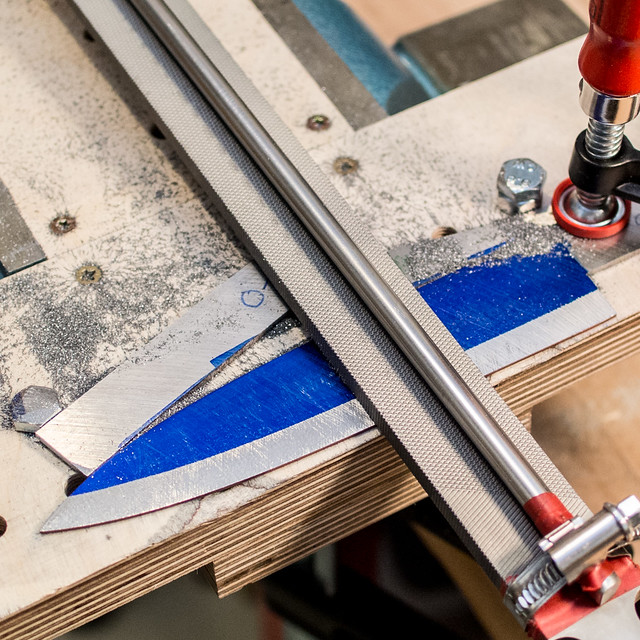

Grinding my first kitchen knife blade

... and here is the knife finished

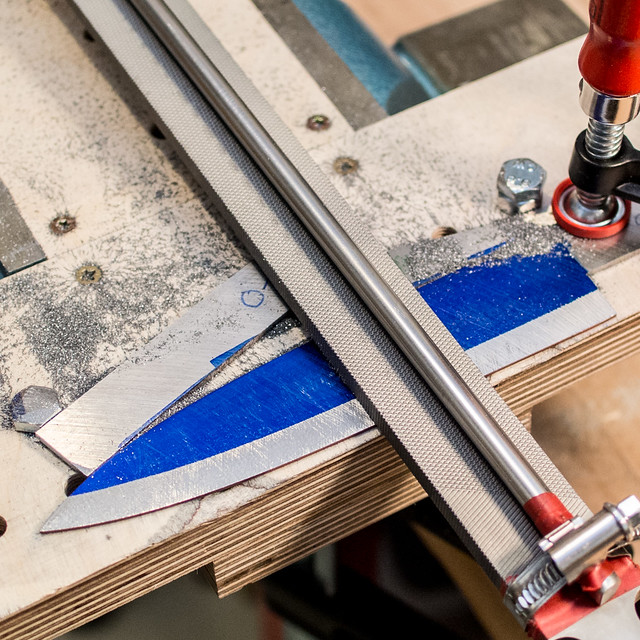

Grinding my first gyuto ... in D2 ...

... hand sanding it - this took for ever ...

... and the finished knife after 25 hours of work in total

Birch bark handle for a puukko Polar blade - this was a fun project that turned out really well

I am working on 8 of these, 4 are already ready for HT

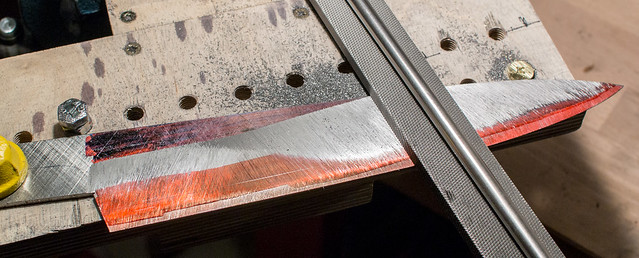

Hide Gyuto before refinish ...

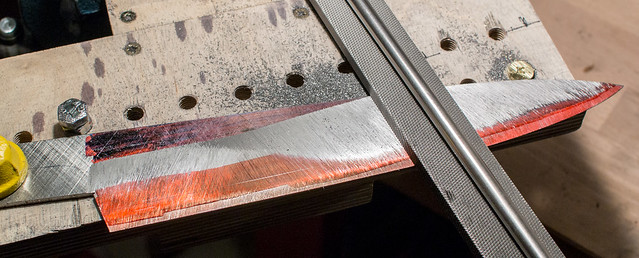

... and after (not quite finished in this photo, but nearly there)

And I am about to rehandle this 2 little guys (in the process of choosing material)

My knifemaking activities so far are mostly concentrated on WA handled knifemaking and making WA handles for existing blades/knives. The only gyuto (that D2 beast that learned me a couple of lessons) is currently on long term loan to a chef in Prague and the feedback has been rather positive - experience like that not only gave me a boost in confidence and motivation, but also is partially responsible for me to join the Hobbyist Craftsman club as this will give me better chance to have my knives tested as the feedback from experienced users is for me crucial to further learn and improve.

I have also thinned and re-finish one Gesshin Hide 225 blue #1 gyuto (will soon appear on my blog) and learned a LOT of respect to guys like Jon who can do such a job in fraction of time.

For the near future I plan to continue focusing on WA handled knives and will leave wester handles for later.

I would also like to use this post to thank all those craftsmen from KKF than have been (and are) very helpful and supportive as their advices have often spared me running in the wrong direction or just missing the better/easier/more reliable way to do things.

I am really enjoying the process. I hope that I should soon have a proper 2x72" grinder that should allow me to improve and speed up many parts of the process. So stay tuned

This thread would be worthless without pictures, so here are a few (most of these have been posted around here) of the work I have done until today:

Grinding my first kitchen knife blade

... and here is the knife finished

Grinding my first gyuto ... in D2 ...

... hand sanding it - this took for ever ...

... and the finished knife after 25 hours of work in total

Birch bark handle for a puukko Polar blade - this was a fun project that turned out really well

I am working on 8 of these, 4 are already ready for HT

Hide Gyuto before refinish ...

... and after (not quite finished in this photo, but nearly there)

And I am about to rehandle this 2 little guys (in the process of choosing material)