Idea for this project was born when a friend of mine bought a 2nd hand, 'well used' special Gesshin Hide 225 blue #2 gyuto which quickly proved to be in a dire need for a complete overhaul. The knife was neglected, thick behind the edge and (as some communication with Jon revealed) was on the of first of its kind and had a very thick tip.

After some some discussions with my friend we agreed that I would try to thin and re-finish the knife. I have only thinned a monosteel O1 petty before and expected that this would be a simples job because of the soft cladding. Well, that was not the case. Not only it turned out to be a lot of work, the blade also had a strongly asymmetrical grind with left side have a concave 'groove' higher up the blade for about 70% of the length of the blade. This meant I had to concentrate mostly on the right side if I wanted to preserve the geometry.

I have wrote an article on the whole process on my blog, here just a few photos.

I am only a little mad at myself as I was under time pressure and did not manage to make the photos I would have liked. It took me about 10 hours to thin and refinish the blade with quite a few lessons learned.

Before I started:

Early stage of thinning with Atoma 140

Knife thinned with Atoma 140 and with distal taper ground-in

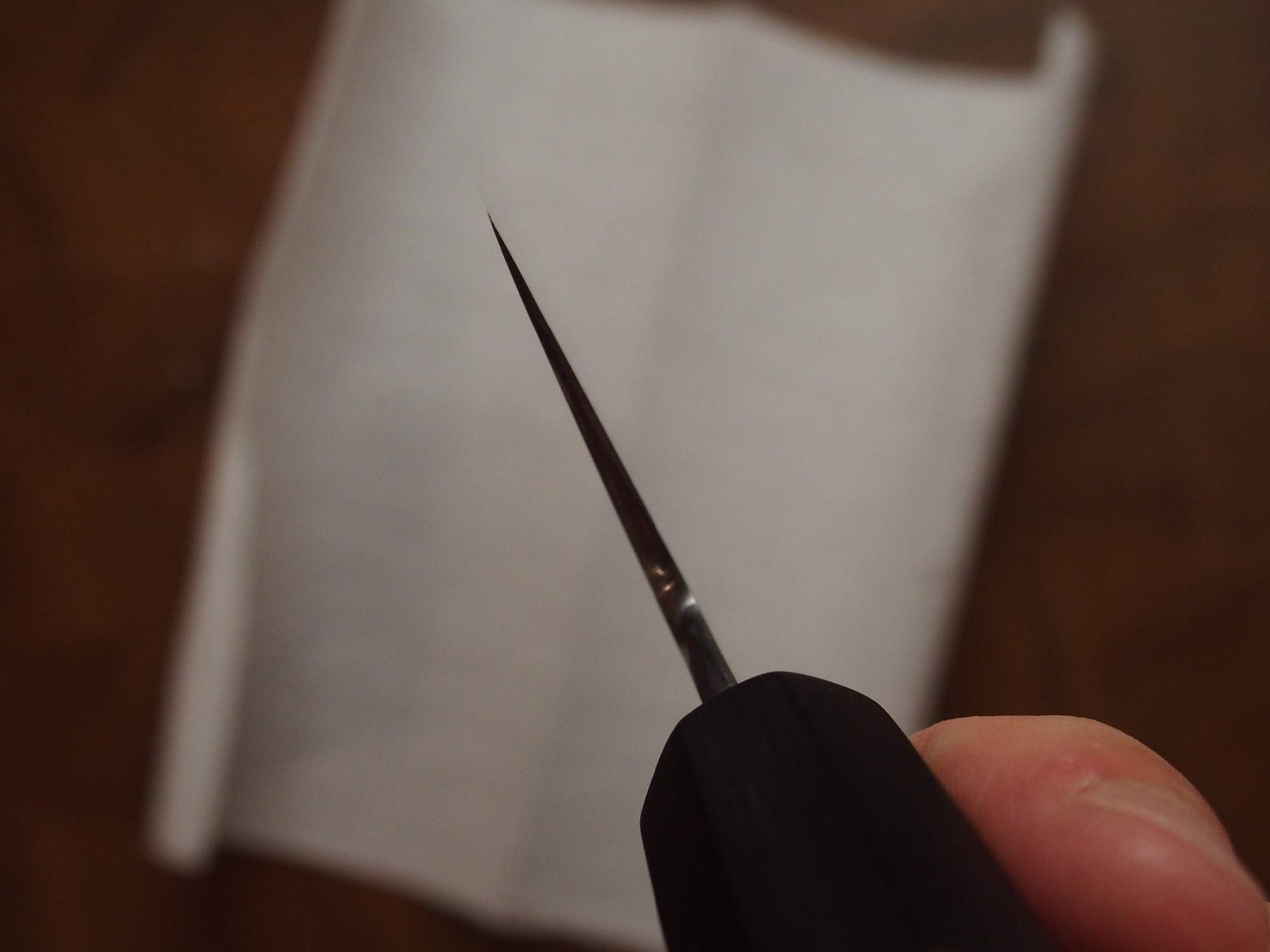

Blade finished to #2500 grit with wet sandpaper (far from perfect)

After some work with fingerstones

After some some discussions with my friend we agreed that I would try to thin and re-finish the knife. I have only thinned a monosteel O1 petty before and expected that this would be a simples job because of the soft cladding. Well, that was not the case. Not only it turned out to be a lot of work, the blade also had a strongly asymmetrical grind with left side have a concave 'groove' higher up the blade for about 70% of the length of the blade. This meant I had to concentrate mostly on the right side if I wanted to preserve the geometry.

I have wrote an article on the whole process on my blog, here just a few photos.

I am only a little mad at myself as I was under time pressure and did not manage to make the photos I would have liked. It took me about 10 hours to thin and refinish the blade with quite a few lessons learned.

Before I started:

Early stage of thinning with Atoma 140

Knife thinned with Atoma 140 and with distal taper ground-in

Blade finished to #2500 grit with wet sandpaper (far from perfect)

After some work with fingerstones