milkbaby

Well-Known Doofus

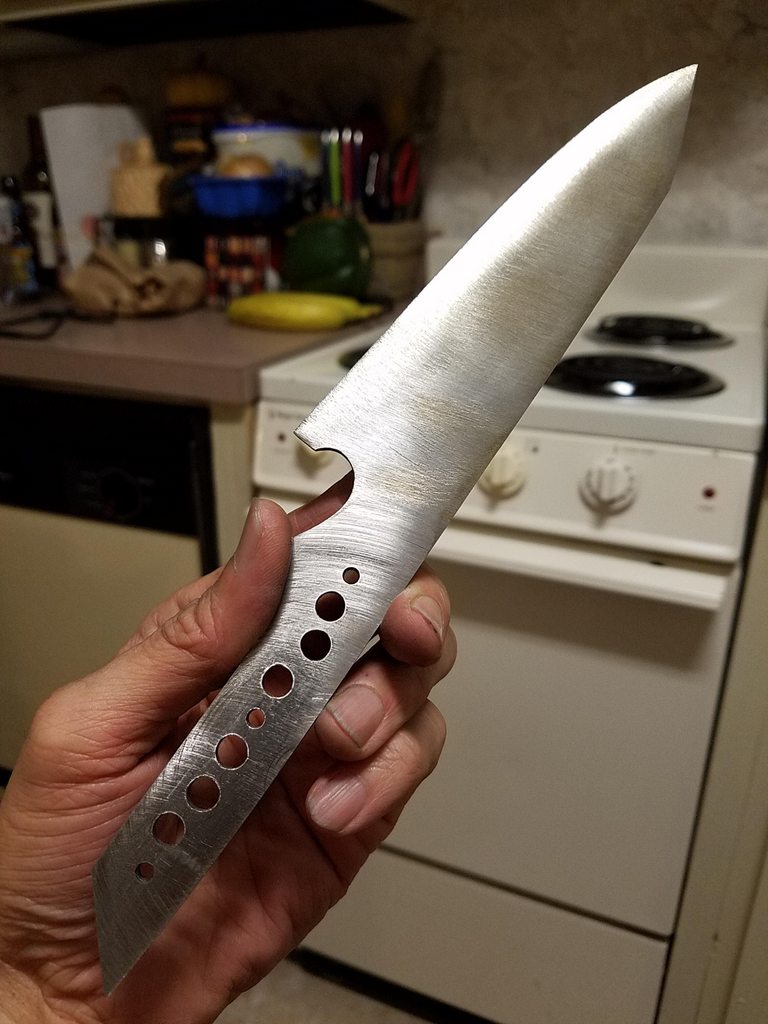

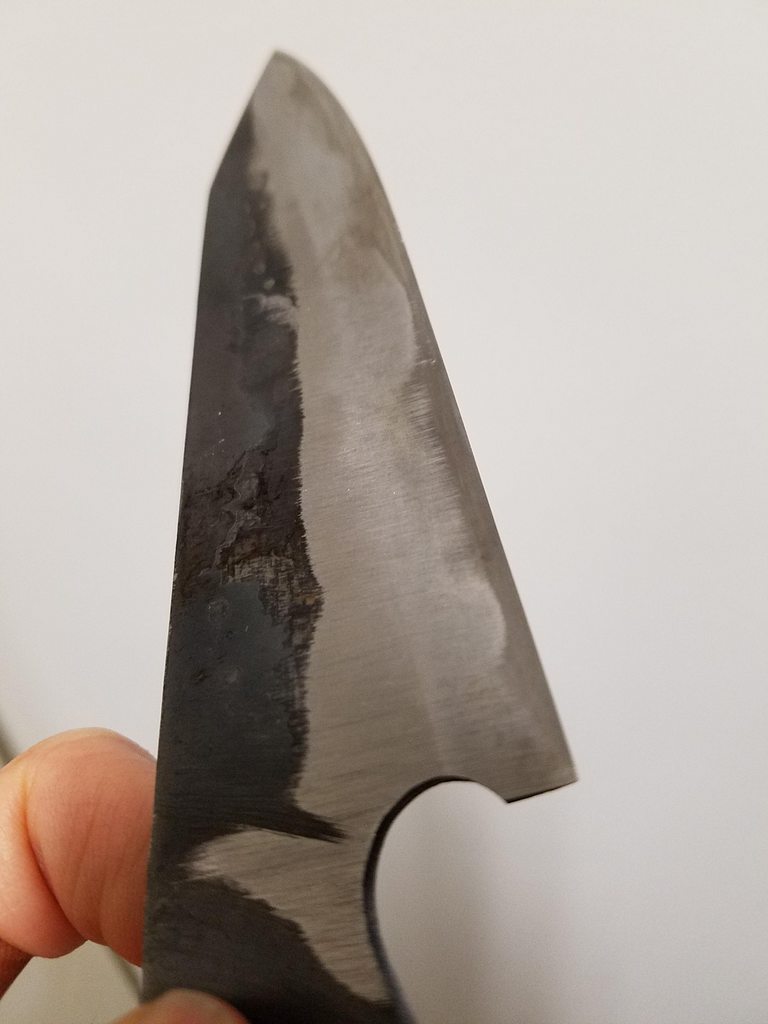

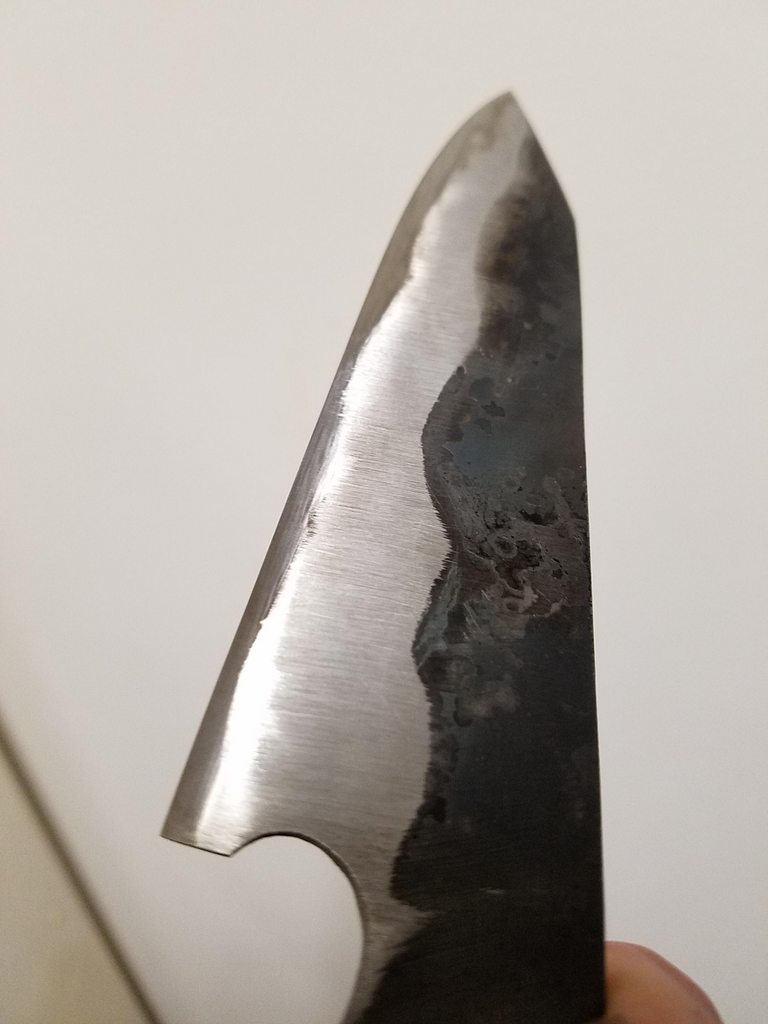

So, I made my first knife by stock removal of 1084 and propane torch heat treat. Not sure I got the heat treat right, but the edge seemed hard. I tried to thin the blade post-heat treat on a silicon carbide stone and dished the stone horribly, LOL, I had to retemper at a higher oven temp. I learned that I need better way to heat treat instead of heating by torch with the blade inside the hole of a concrete block, so I have some soft insulating firebricks on order to make a miniforge.

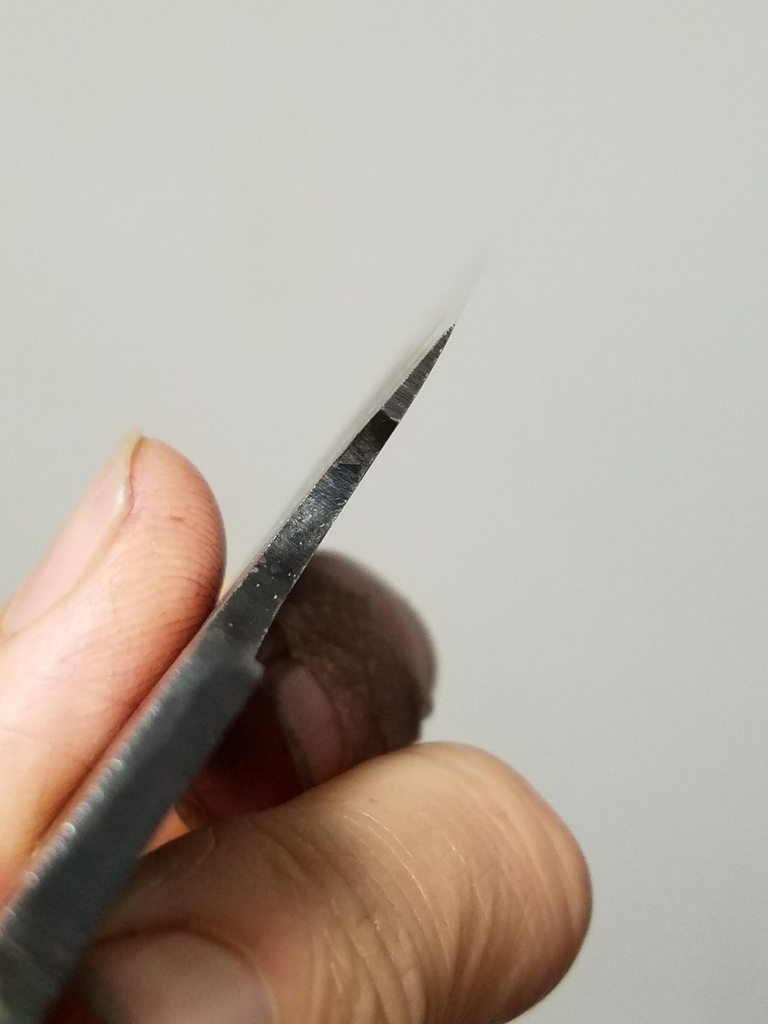

Anyhow, I realized that in my inpatience, I didn't grind the blade thin enough. It started out as 1/8 inch stock and it seemed like I was grinding forever. I thinned it out down by the edge considerably post-HT, but it's still a bit too thick to cut large carrots well. It cuts zucchini nicely tho, I got the edge sharp enough that it's sticking in my board if I'm not careful.

I still have more than three feet of this steel left to make more knives and I'm wondering if I'll ever get the hang of grinding it down with the belt sander (1x30). It felt like I was making it convex at the top and bottom with the fattest part not at the spine. I think part of that was I was too aggressive grinding at the start and saw that I had a few bad low spots, so I went conservative later on and didn't grind enough.

Since I'm wanting to make some kitchen knives which need to be fairly thin for good performance, any tips for grinding the starting stock down thin enough? Is it just a matter of being patient? My lowest grit belts are 50 grit zirconia. I was originally planning to start with thinner stock, but the price and rep for 1084 from NJ Steel Baron/Aldo was too good to pass up.

Anyhow, I realized that in my inpatience, I didn't grind the blade thin enough. It started out as 1/8 inch stock and it seemed like I was grinding forever. I thinned it out down by the edge considerably post-HT, but it's still a bit too thick to cut large carrots well. It cuts zucchini nicely tho, I got the edge sharp enough that it's sticking in my board if I'm not careful.

I still have more than three feet of this steel left to make more knives and I'm wondering if I'll ever get the hang of grinding it down with the belt sander (1x30). It felt like I was making it convex at the top and bottom with the fattest part not at the spine. I think part of that was I was too aggressive grinding at the start and saw that I had a few bad low spots, so I went conservative later on and didn't grind enough.

Since I'm wanting to make some kitchen knives which need to be fairly thin for good performance, any tips for grinding the starting stock down thin enough? Is it just a matter of being patient? My lowest grit belts are 50 grit zirconia. I was originally planning to start with thinner stock, but the price and rep for 1084 from NJ Steel Baron/Aldo was too good to pass up.