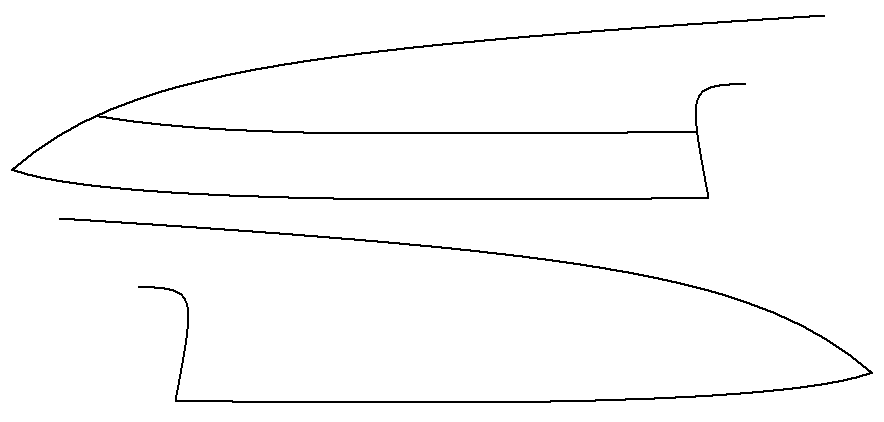

I am looking for a flat-ish profile gyuto, 210-240mm. What I have started to notice is that the profile I am looking for seems much more common for KU knives than for stainless/carbon/clad knives.

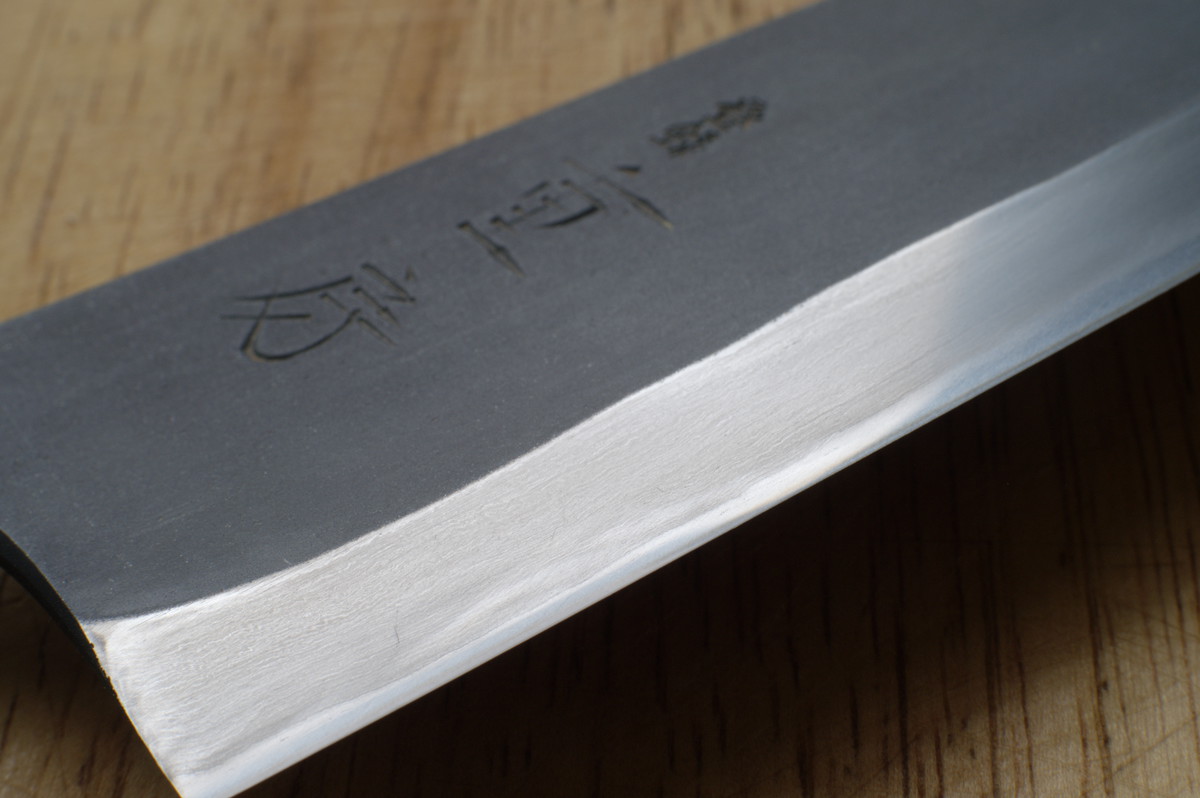

I am not quite sure that KU (or carbon in general) is something for me because of knife care issues. But I find the flat profile (like for example the Munetoshi gyutos) veeeery attractive.

So now I have become curious: why is it that there seem to be relatively many KU knives with a flat profile? Is there a specific reason for this? Or is it part of the general KU knife aesthetics? Or are KU knives bought only by knife nuts that prefer a flat profile?

Very interested in hearing your thoughts!

I am not quite sure that KU (or carbon in general) is something for me because of knife care issues. But I find the flat profile (like for example the Munetoshi gyutos) veeeery attractive.

So now I have become curious: why is it that there seem to be relatively many KU knives with a flat profile? Is there a specific reason for this? Or is it part of the general KU knife aesthetics? Or are KU knives bought only by knife nuts that prefer a flat profile?

Very interested in hearing your thoughts!