milkbaby

Well-Known Doofus

Finished my first gyuto this weekend. Woohooooooo :biggrin:

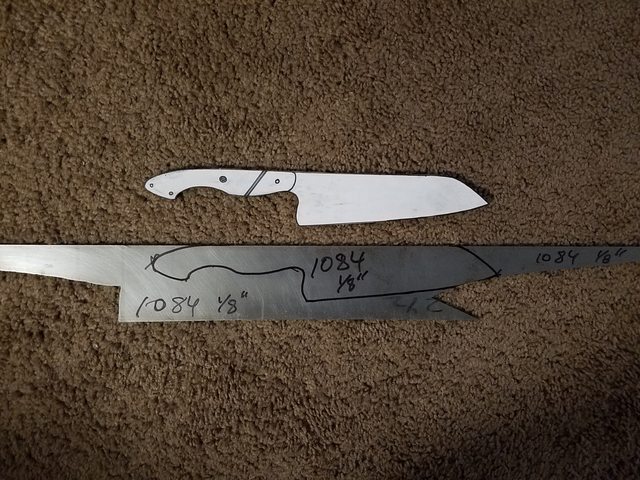

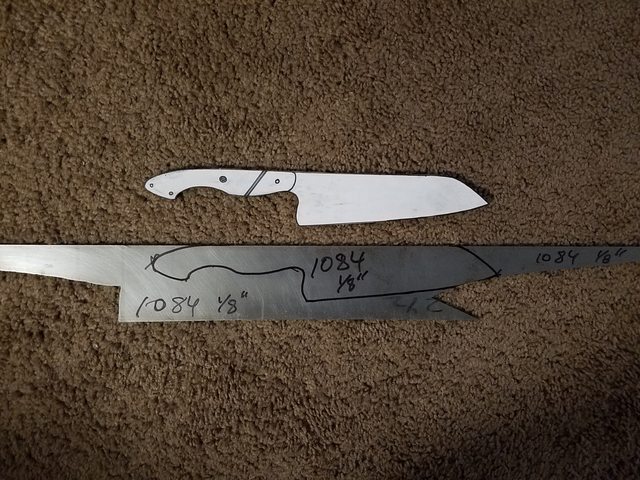

190 mm k-tip gyuto in 1084 carbon steel at about HRc 61-62, full convex grind with slight right handed bias. Handle is full tang with bocote and stabilized dyed maple burl, copper and black G10 spacers, and copper and mosaic pins. Pretty heavy at 7.8 ounces, a huge amount of that weight is from the full tang. I am kinda going for a rustic ghetto fabulous aesthetic... especially since it means getting away with leaving 50 grit grind marks on the blade, LOL.

Balance point right at the finger choil or notch. Just lucky, I guess... Although if making this knife for myself again, I probably wouldn't have done the notch because I usually choke up very high on my pinch grip with middle finger resting right against the choil. So the notch makes me grip even further up the blade.

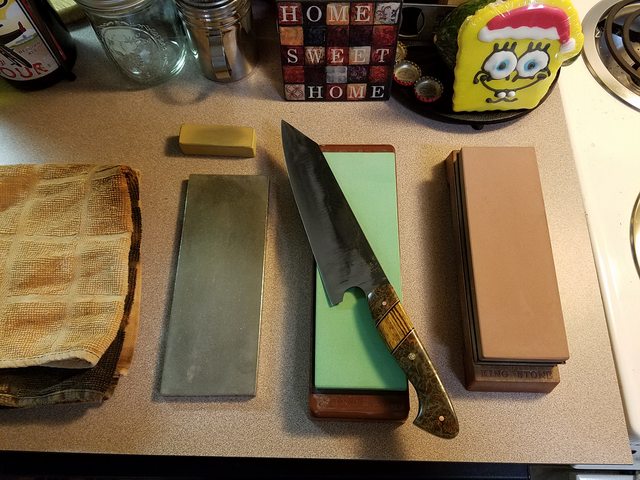

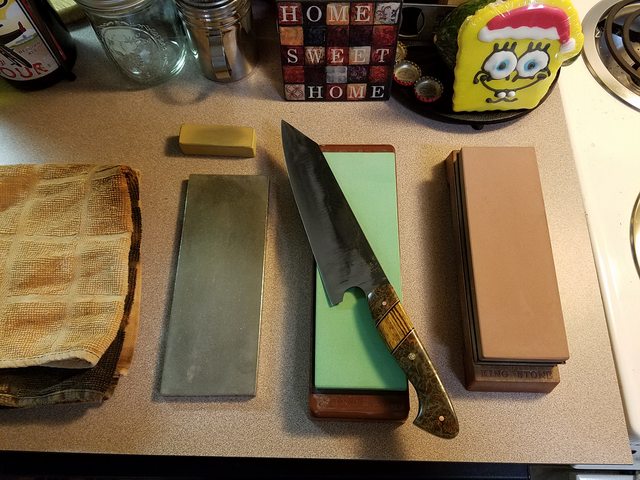

Convex grind (slight right handed bias) to zero with the belt sander and sharpened on DMT XC diamond plate (220 grit), King 400, 1000/6000.

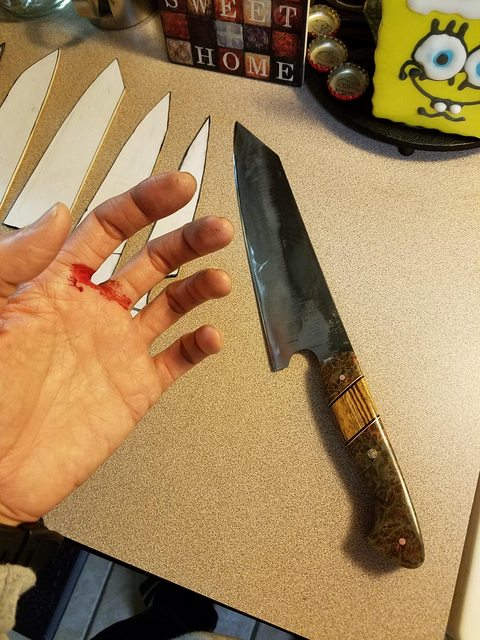

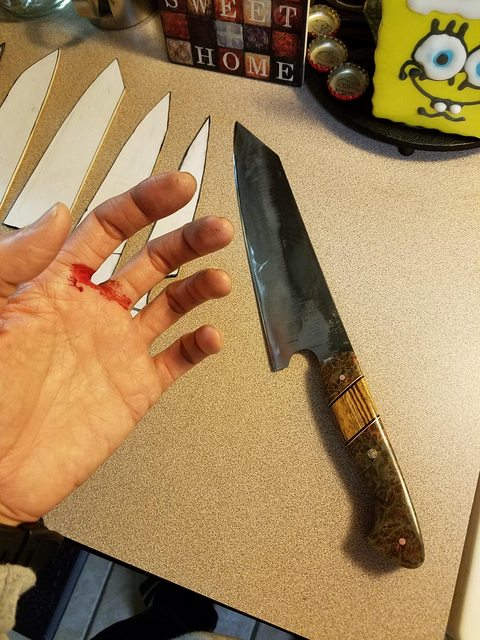

It came out sharp, f* me! First blood...

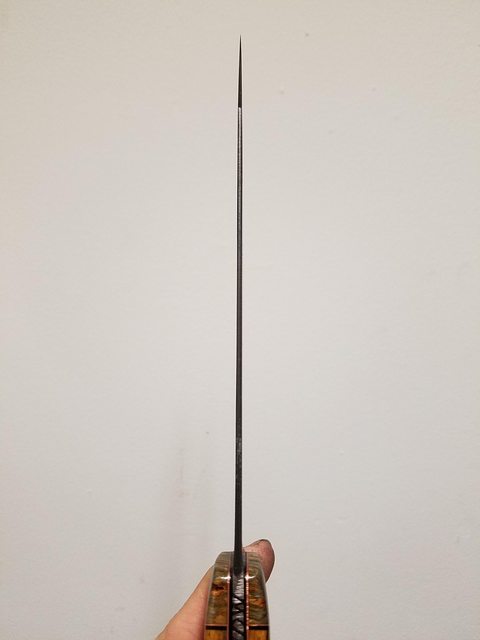

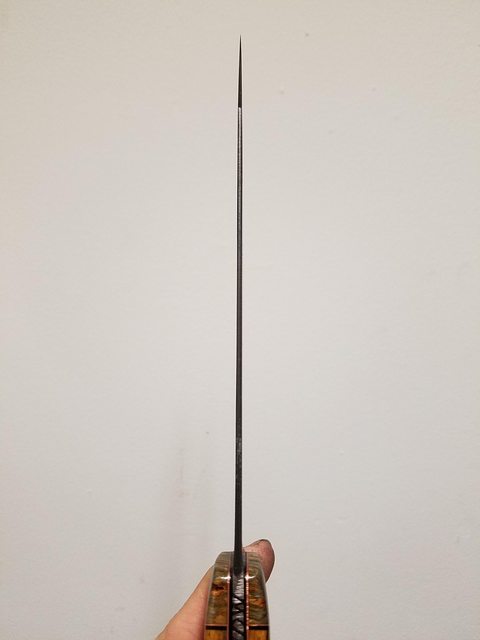

Full distal taper:

Choil pic, a bit distorted from the finger notch:

MOAR PICS! RWARRRRR

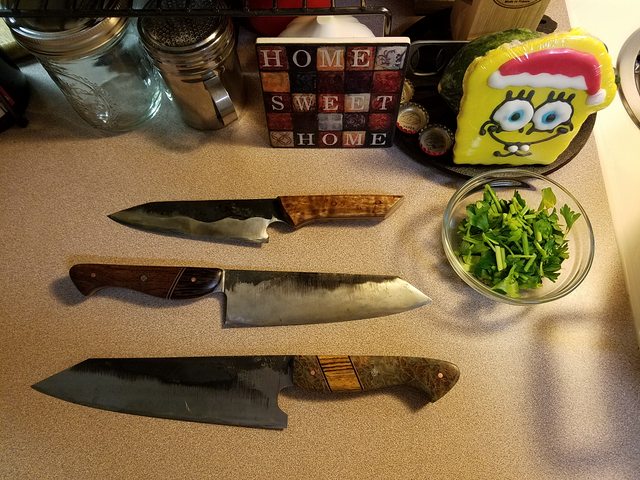

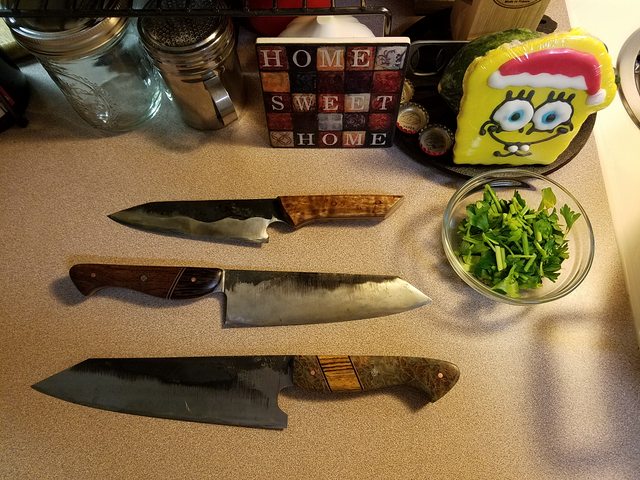

Current family photo, you can probably see the family resemblance:

Next up will probably be my first santoku, a gift for my old boss. I think I may settle into a pattern of one knife for me, one knife to gift. Having a lot of fun learning and trying to get better at this.

190 mm k-tip gyuto in 1084 carbon steel at about HRc 61-62, full convex grind with slight right handed bias. Handle is full tang with bocote and stabilized dyed maple burl, copper and black G10 spacers, and copper and mosaic pins. Pretty heavy at 7.8 ounces, a huge amount of that weight is from the full tang. I am kinda going for a rustic ghetto fabulous aesthetic... especially since it means getting away with leaving 50 grit grind marks on the blade, LOL.

Balance point right at the finger choil or notch. Just lucky, I guess... Although if making this knife for myself again, I probably wouldn't have done the notch because I usually choke up very high on my pinch grip with middle finger resting right against the choil. So the notch makes me grip even further up the blade.

Convex grind (slight right handed bias) to zero with the belt sander and sharpened on DMT XC diamond plate (220 grit), King 400, 1000/6000.

It came out sharp, f* me! First blood...

Full distal taper:

Choil pic, a bit distorted from the finger notch:

MOAR PICS! RWARRRRR

Current family photo, you can probably see the family resemblance:

Next up will probably be my first santoku, a gift for my old boss. I think I may settle into a pattern of one knife for me, one knife to gift. Having a lot of fun learning and trying to get better at this.