zetieum

Senior Member

Review of a 210mm Gyuto made by Robin Dalman in 2016

Specifications:

210 AEB-L gyuto, handle: masur birch, sapele spacer, with reindeer antler ferrule.

Purchased end of December 2016

Profile

I like a lot the profile of this knife. It manages to be both elegant and aggressive. There is something special in Robins knife profile that gives a dynamism to the ensemble. Maybe the heel being not perpendicular to the spine plays a great role in this feeling. The is a lot of clearance for the finger at the heel. This, coupled with the rounded choil makes it very confortable to hold in a pinch grip, at least for me. There is a little flat spot on the first 3-5 cm of the blade. Then starts a very very gentle curve that get progressively more pronounced toward the tip. The progression of the curvature is very smooth giving a lot of flow for rock movements. The tip is pronounced and more pointy than what I usually get on guytos. Nevertheless, it does not feel too pointy/dangerous/fragile. Very well balance. I asked for a rather tall version, and 48 mm is very satisfying for a 210.

Geometry/grind

This knife got the new Robins grind (from December 2016). It is an super-thin S grind, with a slightly hollow bevel. It is a pure winner. You get laser feeling of thinnest on the cut, but with decent food release; moreover the spine is robust. Compared to an older versions I had the opportunity to test, the upper part of the blade is a bit thicker, which adds a lot of robustness and solves flexibility issues. I like it. In short this knife is extremly thin behind the cutting edge, but wiht robust spine. Moreover, the hollow middle of the blade, so called S grind, works very nicely. It also enhances a lot to the global esthetic of the knife.

There is a pronounced distal taper that ends into a thin tip, (but not too thin, as it has been critized in the earlier version). Still the tip is really thin, which makes it a pure onion killer.

Handle

I think the pictures speak for themselves. F a n t a s t i c. Beautiful materials, flawless, perfectly executed. Feels very good in the hand. The nicest handle of my collection (so far). One other thing that I like: all the materials were sourced in Sweeden, where Robin lives, and all the materials are from sustainable sources.

F&F

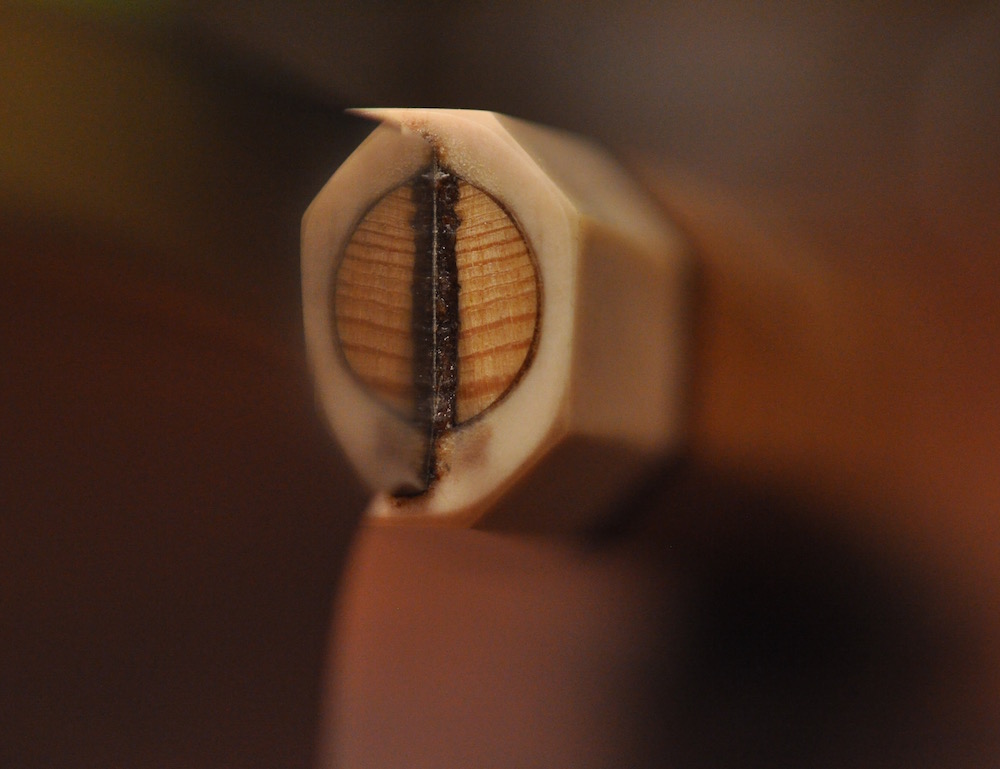

Perfect. Choil and spine are rounded. The insertion of the blade in the handle is beautifull. Flawless. I do not see a point that could be improved.

Insertion of the blade in the handle

Performance

In the last month I used the knife for my cutting tasks (home user). It handled perfectly anything I could throw at it. The profile is very versatile. I am mostly a push cutter, but you can definitively chop and I even rocked with it. Cross chopping was also doable. It feels laser. This knife is a carrot killer that hold well against my to my Shibata Kotetsu (my reference in carrot extermination). Onions get diced by themselves when they see the knife on the board. Horizontal, verticals, like there is no tomorrow. The tip is really impressive in all aspect for that: the conjugaison of both thinnest and pointiness makes miracle. It managed well also butternuts and apples. No problem with soft ingedients, neither with rolling peppers. On protein it managed better than I thought, but clearly knives a bit thicker and with a convex manage better. Food release is very good for a knife that thin BUT do not expect miracles: it is a laser. There is always some kind of trade-off between cutting performance and FR. Robin aims at performance, but the knife still has a very decent FR: the S grind may certainly play sin big role here.

I also share here a video from Robin that he made to show me the performance of the knife before ending it:

[video=youtube_share;j3XuRFS8C-g]http://youtu.be/j3XuRFS8C-g[/video]

Steel etc.

Since I have it, I did not sharpen it. I just put it few time on stop on bare leather, which was sufficient to give a novel freshness to the edge. So edge retention is far much better than what I was expected for AEB-L; although I am usually very gentle with my edges. I will update this thread after my first sharpening.

In short, it is a laser-like knife that provides great confidence. Confidence because it is very easy to handle and manipulate. Agile, but not fragile. It goes though food easily. I love it.

The purchase and making process

When buying a custom or semi-custom knife, we do not only by a blade, we also undergo discussions with the maker about what we want, what he offers, what he proposes, the options etc. This process is really part of the buying experience and it is, to me, extremely important. In this regard, the experience with Robin has been absolutely great. We exchanged a lot on the knife but also on other things: grind, type of finish, instagram, knife forums, knife making buisness etc (>75 mails altogether!). Through those discussions, I have learned and I have enjoyed them a lot. During the whole process, Robin has been very active and reactive in communicating: sending pictures (and instagram lnk) to help making me an idea of the options, but also pictures of the knife at some decisive points, videos etc. In short everything more than perfect. As a customer, I rarely had, in any kind of business, had the feeling of being so well informed and taken care of. Just perfect.

I thought it may be interesting to describe how it went a bit more. I sent a mail to Robin to tell him that I was interested in his work at the end of June 2016. Robin answered me the day after. After a week of daily mail exchanges, we settled on a 210 guyto, tall, with strongly figured birch masur handle and eindeer antler ferrule, with a delay of making of ~2 months. Few weeks after, Robin informed me that there would be some extra delay, which was no problem to me: I always expect additional delay for craftman work. But unlike what I have experienced before: Robin warned me of the extra delay before in a proactive manner, and more than one month ahead of the dead line. Extremely professional. At the end of September Robin sent me pictures of my blade on which he tried a novel finish, and with the option of having the finish changed. After some discussions, we agree on changing few things. Finally, in the beginning of November the knife was ready, and after final approvals Robin send me the knife. Bill, payment, shipment, packaging: every thing was flawless.

I was amazed by the look etc, but, after few days of testing I was not pleased with the performance. It was wedging too much taste. I contacted Robin, and and then something great happened: I understood what PERFECT service means. Robin answered directly saying that he was very sorry that I was not 100% satisfy with the knife and offered to retake it to work on it. He proposed to put his new slightly hollow grind on it and to refinish it, he also directly offered to give me a small second paring knife to bribe me with the return shipping (see below). That is what I call making everything to make you customer satisfied, and I was.

I sent the knife back, Robin put it on his priority list, and after a couple of weeks the knife was ready. Robin sent me pictures and a video for approval. I received the knife just before xmas (I took longer because I also asked Robin to do a custom-handle on another knife). And it was just perfect.

That is the "second" paring knife. Do I need to say that it is actually the best paring knife I have?

To conclude: when you buy a knife from Robin, you buy more than a knife: you buy a guarantied 100% satisfying knife and a great human experience.

Robin: Thank you, thank you, thank you, thank you, thank you, thank you, thank you, thank you, thank you, thank you.