nkbitsch

Well-Known Member

- Joined

- Jan 1, 2017

- Messages

- 91

- Reaction score

- 0

A couple of weeks ago I received my first Kato. I was overly excited to open the parcel from JNS, as I had heard so many good things about the knives from Kiyoshi-san.

After tearing the parcel apart, I finally got a glimpse of the black box! But when I first opened it, it was like everything fell part for me. I had heard that the finish on these knives was so-so, but this finish on this one was IMO terrible. It had scratches in every direction, and one across the blade was so deep that I even felt that I could feel it with my finger-nail. :scared4:

Well, looks isn't everything, and what is not to be fixed with the right surgery? :spiteful:.

I started to use the knife, and finally I felt the Kato magic! It was a joy using the knife, and for the following two weeks it was my knife of choice for every task.

But, as I just received some other knifes, I have decided to spend my evenings this week, giving the Kato the makeover that it deserves.

My plan is to give it a beautiful Kasumi finish. I have never tried this before, but I have a good idea about the procedure.

I spend about 4 hours today removing the vertical scratches on the blade. I went from 180 grit to 400 grit to 600 g. to 800 g. to 1000 g., though I wasn't satisfied with the removing of the vertical scratches, so I decided to go back to 180 grit, continuing to 400 and 600 grit.

My plan is to take it all the way to 8000 grit before finishing off with Uchigomori fingerstones.

Though, I just don't seem to be able to get rid of the vertical scratches on the Ha-part, and I am quite sure that KKF is the right place to seek help :biggrin:.

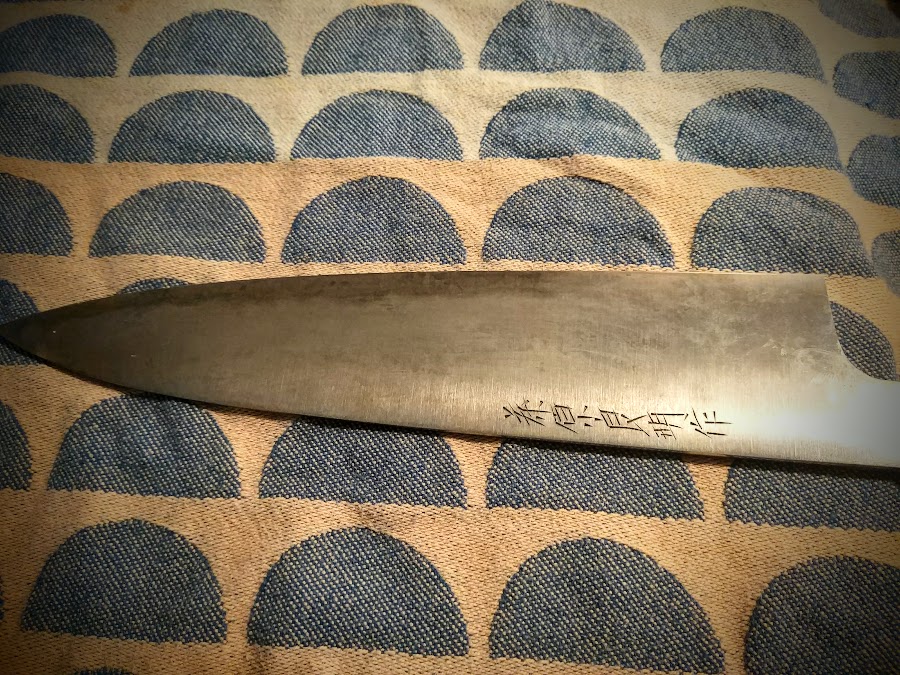

Here's a picture from before and after 600 grit. I will keep the thread updated with pictures of the process, but really need some advice on removing the vertical scratches on the Ha-part.

Before:

After 600 grit:

After tearing the parcel apart, I finally got a glimpse of the black box! But when I first opened it, it was like everything fell part for me. I had heard that the finish on these knives was so-so, but this finish on this one was IMO terrible. It had scratches in every direction, and one across the blade was so deep that I even felt that I could feel it with my finger-nail. :scared4:

Well, looks isn't everything, and what is not to be fixed with the right surgery? :spiteful:.

I started to use the knife, and finally I felt the Kato magic! It was a joy using the knife, and for the following two weeks it was my knife of choice for every task.

But, as I just received some other knifes, I have decided to spend my evenings this week, giving the Kato the makeover that it deserves.

My plan is to give it a beautiful Kasumi finish. I have never tried this before, but I have a good idea about the procedure.

I spend about 4 hours today removing the vertical scratches on the blade. I went from 180 grit to 400 grit to 600 g. to 800 g. to 1000 g., though I wasn't satisfied with the removing of the vertical scratches, so I decided to go back to 180 grit, continuing to 400 and 600 grit.

My plan is to take it all the way to 8000 grit before finishing off with Uchigomori fingerstones.

Though, I just don't seem to be able to get rid of the vertical scratches on the Ha-part, and I am quite sure that KKF is the right place to seek help :biggrin:.

Here's a picture from before and after 600 grit. I will keep the thread updated with pictures of the process, but really need some advice on removing the vertical scratches on the Ha-part.

Before:

After 600 grit: