Johan van Zanten is, as far as I know, the only professional kitchen knife maker in the Netherlands and one of the few self-employed ones in Europe. He is not very active on social media, which is where I get most of my information from about kitchen knives, so it took a while before we got to know each other. But then it appeared he works in the same town where I live. It is only a 10-minute drive by car...

Once we had gotten to know each other and each other's work, Johan asked me to test one of his knives. Of course, I was happy to do so. And I was even happier when I found out this is a very special knife. Which you can read in the remainder of this review.

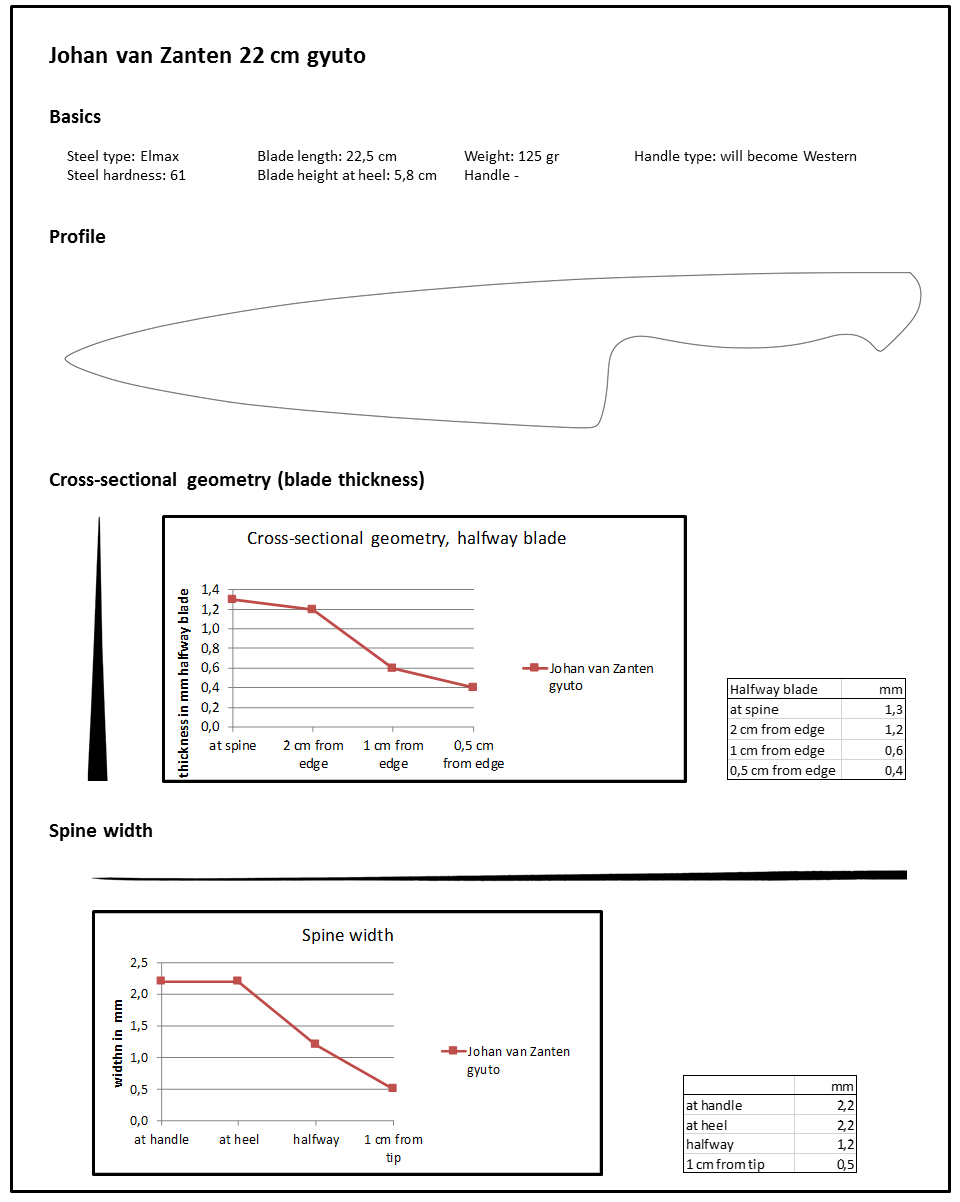

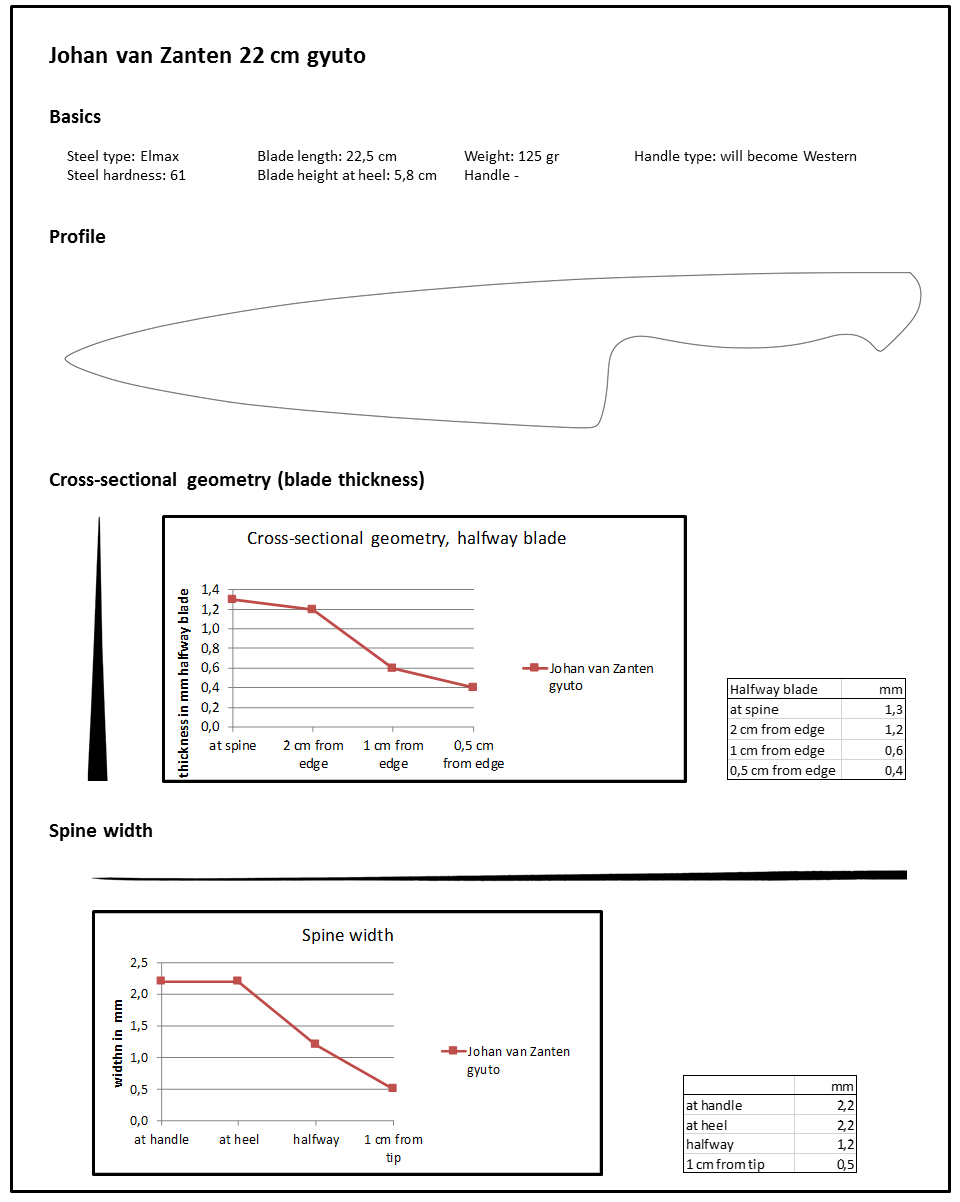

Geometry

Normally I start a review with a description of the appearance or fit and finish of a knife, but this knife has such a special geometry I have to tell you that first. Johan describes his knife as having a double hollow grind and I think this is an accurate description. It consists of a hollow part near the spine and a concave (also a kind of hollow) part near the edge. This results in a ridge about halfway the knife. I measured the ridge at various places (1/4, 1/2 and 3/4 of the length of the knife) and at every place the ridge was about as thick as the spine.

The grind is supposed to (andas we shall seedoes) aid in food release. In addition, the concavity makes the part just above the edge quite thin, resulting in a knife that hardly wedges.

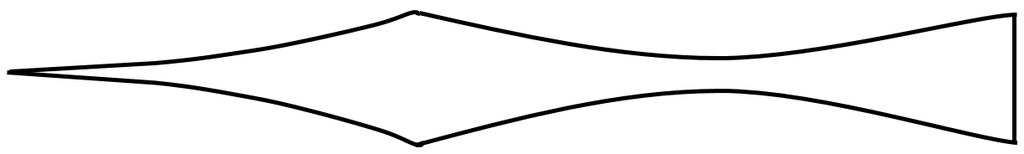

I hope the photographs below can show this grind well, even though they don't represent the hollow part as good as it is in reality. The picture below the photographs gives an (exaggerated) representation of the grind.

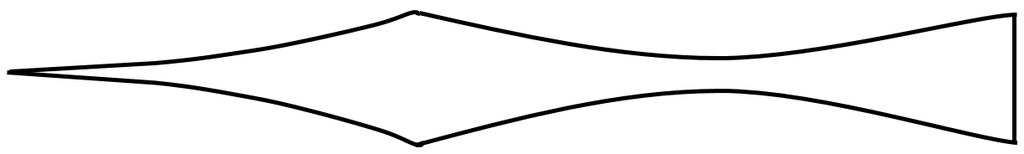

Exaggerated view of the geometry. The upper hollow part, on the right the picture, and the lower concave part (also a kind of hollow), on the left, have the same radius.

Next to this special grind, the knife has a number of other remarkable features. It is very thin just above the edge: 0.4 mm half a centimeter above the edge, which is the thinnest I have ever measured. It is also very thin near the tip: 0.5 mm one centimeter from the tip. Again this is the thinnest I have ever measured.

Profile

I'd describe the profile as mainly Western-oriented. The edge has a nice curve, but also a flat spot. It is very suitable for rock chopping, but I had no problems push cutting either.

An interesting feature of the knife is that it is 5.8 mm high at the heel, higher than any other knife I have tested.

The tip of the knife is a bit blunt, but Johan explained that this was because it is a prototype knife and he will restore it of course if he makes it into a commercial knife.

Fit and finish

The knife isn't finished yet, so it is hard to give a complete assessment of the fit and finish. But what I've seen is very good. Both the spine and choil have been finished nicely. And the blade was polished to a high degree.

On Johan's site you can see more examples of his knives and the fit and finish of these knives appears not only impeccable, but very beautiful, too.

Use

When I start using a knife, I usually first sharpen it. That was definitely not necessary with this knife, since it was very sharp. However, I was interested in the steel, Elmax, so I did sharpen it later. I can say that, in spite of the fact that the knife has a high wear resistance (and quite a good toughness, too), it can be sharpened quite easily. The only thing is that this knife has some flexibility from about 1/3 of the tip (slightly more flexibility than a Robin Dalman knife, I'd say), which may make sharpening a bit more difficult.

I've used the knife almost continuously for about 1.5 months as a home cook. As I wrote, I sharpened the knife, but the wear resistance of the knife certainly did not make this necessary.

I thoroughly enjoyed using the knife. The fact that it is so thin above the edge made that it never wedged. And its thin tip made it ideal for cutting fine ingredients. And... it has a great food release, I'd say the best of all knives I have tested. Cutting potatoes was a joy. The only thing you must like is that it has some flexibility. I do, partly because it is a consequence of a thin knife and a great distal taper. But, for example, it also helps in things like cutting bell peppers. And the flexibility never bothered me: one hardly applies a considerable amount of lateral force to the end of the knife.

Conclusion

This is one of the most special knives I have ever tested: very thin above the edge, a very thin tip and a special grind that may make food release better than on any of the other knives I have tested. It was a joy to cut with it every day. Unfortunately I have to return the knife, but fortunately I have already placed an order for a new one...

Examples of beautiful finished knives, including Damascus ones, can be found on Johan's site.

Factsheet

I did include a choil shot in the factsheet, but you should realize the double hollow profile starts only a centimeter or so after the choil. So this profile is not shown in the choil shot.

Once we had gotten to know each other and each other's work, Johan asked me to test one of his knives. Of course, I was happy to do so. And I was even happier when I found out this is a very special knife. Which you can read in the remainder of this review.

Geometry

Normally I start a review with a description of the appearance or fit and finish of a knife, but this knife has such a special geometry I have to tell you that first. Johan describes his knife as having a double hollow grind and I think this is an accurate description. It consists of a hollow part near the spine and a concave (also a kind of hollow) part near the edge. This results in a ridge about halfway the knife. I measured the ridge at various places (1/4, 1/2 and 3/4 of the length of the knife) and at every place the ridge was about as thick as the spine.

The grind is supposed to (andas we shall seedoes) aid in food release. In addition, the concavity makes the part just above the edge quite thin, resulting in a knife that hardly wedges.

I hope the photographs below can show this grind well, even though they don't represent the hollow part as good as it is in reality. The picture below the photographs gives an (exaggerated) representation of the grind.

Exaggerated view of the geometry. The upper hollow part, on the right the picture, and the lower concave part (also a kind of hollow), on the left, have the same radius.

Next to this special grind, the knife has a number of other remarkable features. It is very thin just above the edge: 0.4 mm half a centimeter above the edge, which is the thinnest I have ever measured. It is also very thin near the tip: 0.5 mm one centimeter from the tip. Again this is the thinnest I have ever measured.

Profile

I'd describe the profile as mainly Western-oriented. The edge has a nice curve, but also a flat spot. It is very suitable for rock chopping, but I had no problems push cutting either.

An interesting feature of the knife is that it is 5.8 mm high at the heel, higher than any other knife I have tested.

The tip of the knife is a bit blunt, but Johan explained that this was because it is a prototype knife and he will restore it of course if he makes it into a commercial knife.

Fit and finish

The knife isn't finished yet, so it is hard to give a complete assessment of the fit and finish. But what I've seen is very good. Both the spine and choil have been finished nicely. And the blade was polished to a high degree.

On Johan's site you can see more examples of his knives and the fit and finish of these knives appears not only impeccable, but very beautiful, too.

Use

When I start using a knife, I usually first sharpen it. That was definitely not necessary with this knife, since it was very sharp. However, I was interested in the steel, Elmax, so I did sharpen it later. I can say that, in spite of the fact that the knife has a high wear resistance (and quite a good toughness, too), it can be sharpened quite easily. The only thing is that this knife has some flexibility from about 1/3 of the tip (slightly more flexibility than a Robin Dalman knife, I'd say), which may make sharpening a bit more difficult.

I've used the knife almost continuously for about 1.5 months as a home cook. As I wrote, I sharpened the knife, but the wear resistance of the knife certainly did not make this necessary.

I thoroughly enjoyed using the knife. The fact that it is so thin above the edge made that it never wedged. And its thin tip made it ideal for cutting fine ingredients. And... it has a great food release, I'd say the best of all knives I have tested. Cutting potatoes was a joy. The only thing you must like is that it has some flexibility. I do, partly because it is a consequence of a thin knife and a great distal taper. But, for example, it also helps in things like cutting bell peppers. And the flexibility never bothered me: one hardly applies a considerable amount of lateral force to the end of the knife.

Conclusion

This is one of the most special knives I have ever tested: very thin above the edge, a very thin tip and a special grind that may make food release better than on any of the other knives I have tested. It was a joy to cut with it every day. Unfortunately I have to return the knife, but fortunately I have already placed an order for a new one...

Examples of beautiful finished knives, including Damascus ones, can be found on Johan's site.

Factsheet

I did include a choil shot in the factsheet, but you should realize the double hollow profile starts only a centimeter or so after the choil. So this profile is not shown in the choil shot.