Kippington

A small green parrot

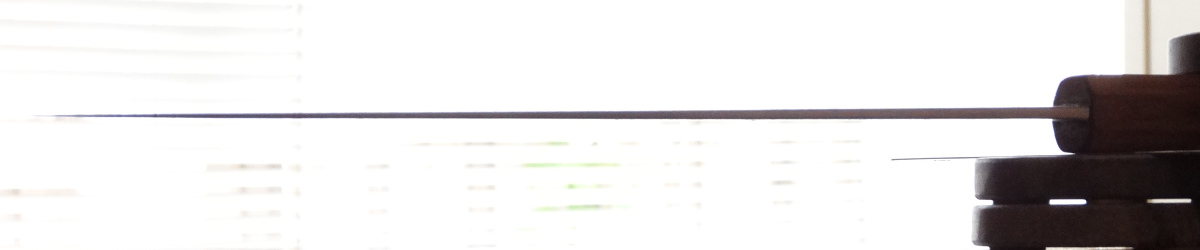

My latest work and the best I've made yet! I'm considering knuckling down and actually polishing this puppy, something I would normally refuse to do. :laugh:

W2 steel hand-forged honyaki (metal plate insulators instead of clay).

250mm edge length, 56mm heel height.

I've managed to copy many of the qualities I consider 'high level' on gyutos made for performance. For example, the top and bottom of the handle meet up with the top and bottom of the emoto (knife neck).

Grind is a very subtle double concave to a convex spine, really hard to catch in a picture:

For my previous knife I got a lot of feedback that it was too fat and heavy. I've fixed the problem on this one by tapering the knife heavily in both length and in height:

I work in a commercial kitchen, and having the ability to take my creation to work is SO MUCH FUN! :lol2:

While its not yet polished, I'm finding it hard to pin-point areas in performance which I can improve.

I gotta go to work now, I'm gonna be late, but when I get back I'll go into more info on the heat treatment and performance - and maybe some videos! :biggrin:

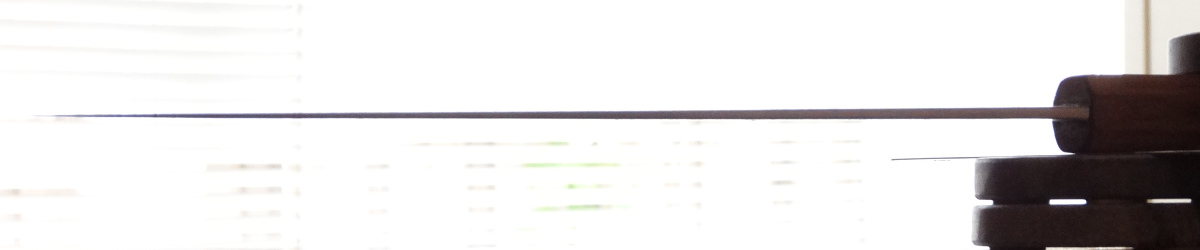

W2 steel hand-forged honyaki (metal plate insulators instead of clay).

250mm edge length, 56mm heel height.

I've managed to copy many of the qualities I consider 'high level' on gyutos made for performance. For example, the top and bottom of the handle meet up with the top and bottom of the emoto (knife neck).

Grind is a very subtle double concave to a convex spine, really hard to catch in a picture:

For my previous knife I got a lot of feedback that it was too fat and heavy. I've fixed the problem on this one by tapering the knife heavily in both length and in height:

I work in a commercial kitchen, and having the ability to take my creation to work is SO MUCH FUN! :lol2:

While its not yet polished, I'm finding it hard to pin-point areas in performance which I can improve.

I gotta go to work now, I'm gonna be late, but when I get back I'll go into more info on the heat treatment and performance - and maybe some videos! :biggrin: