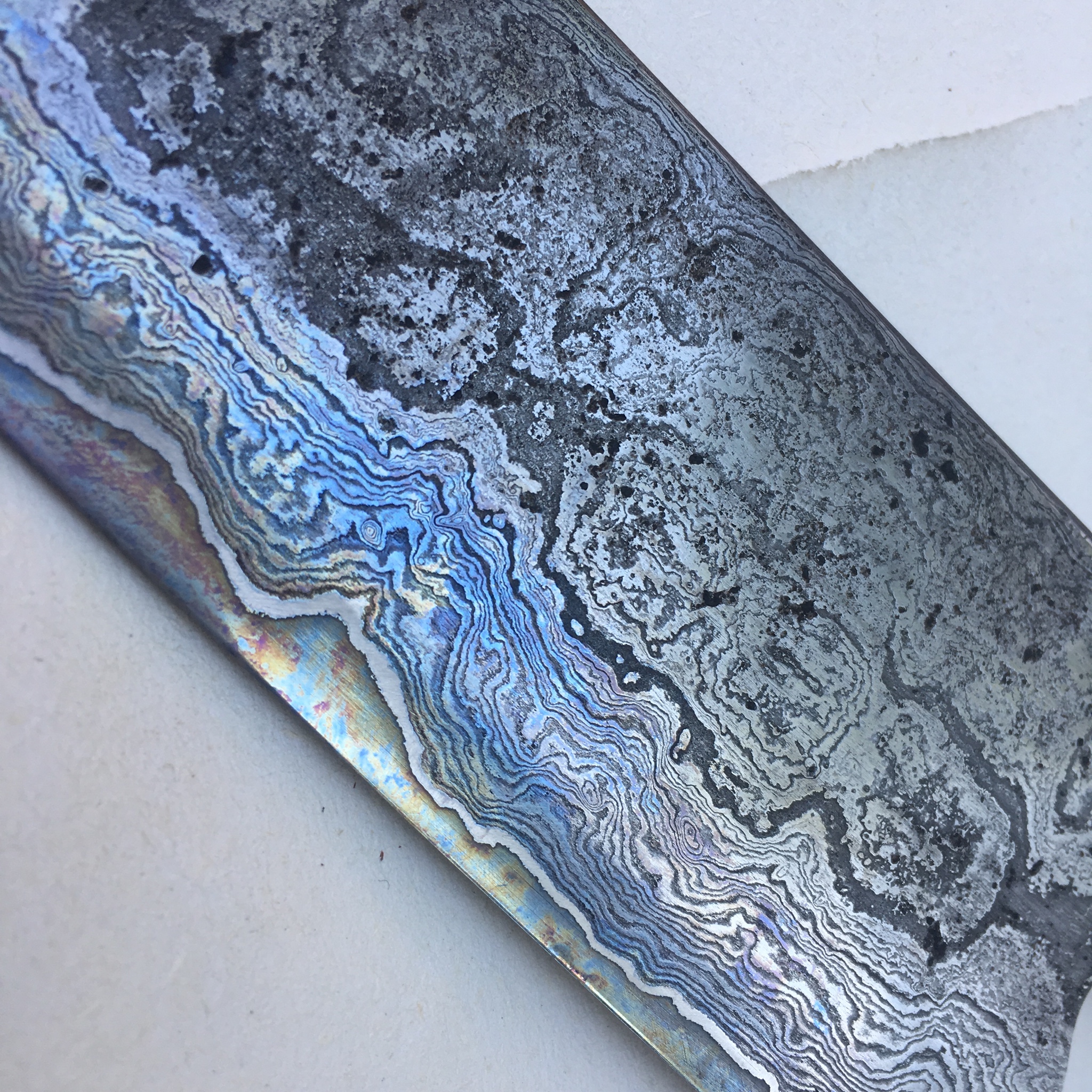

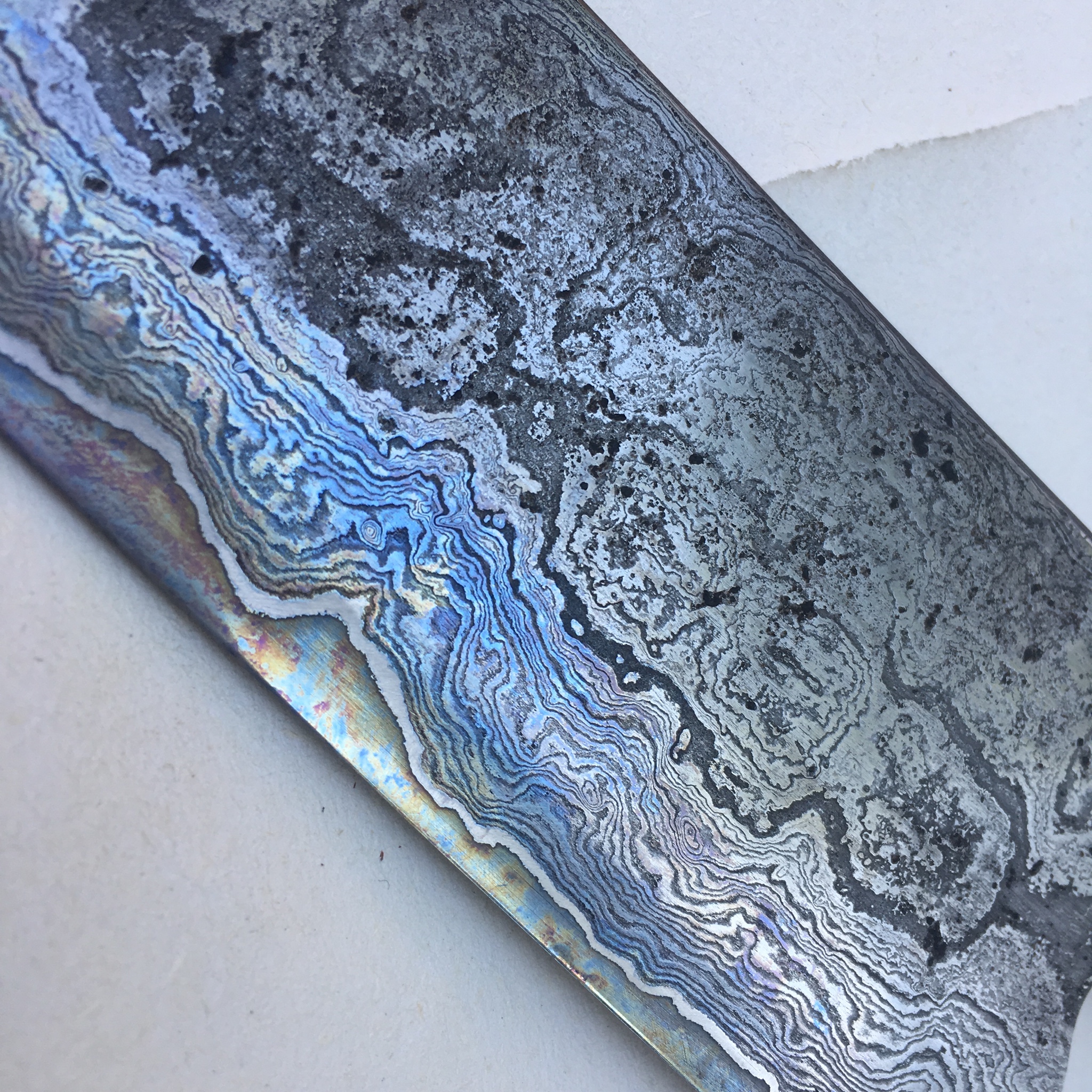

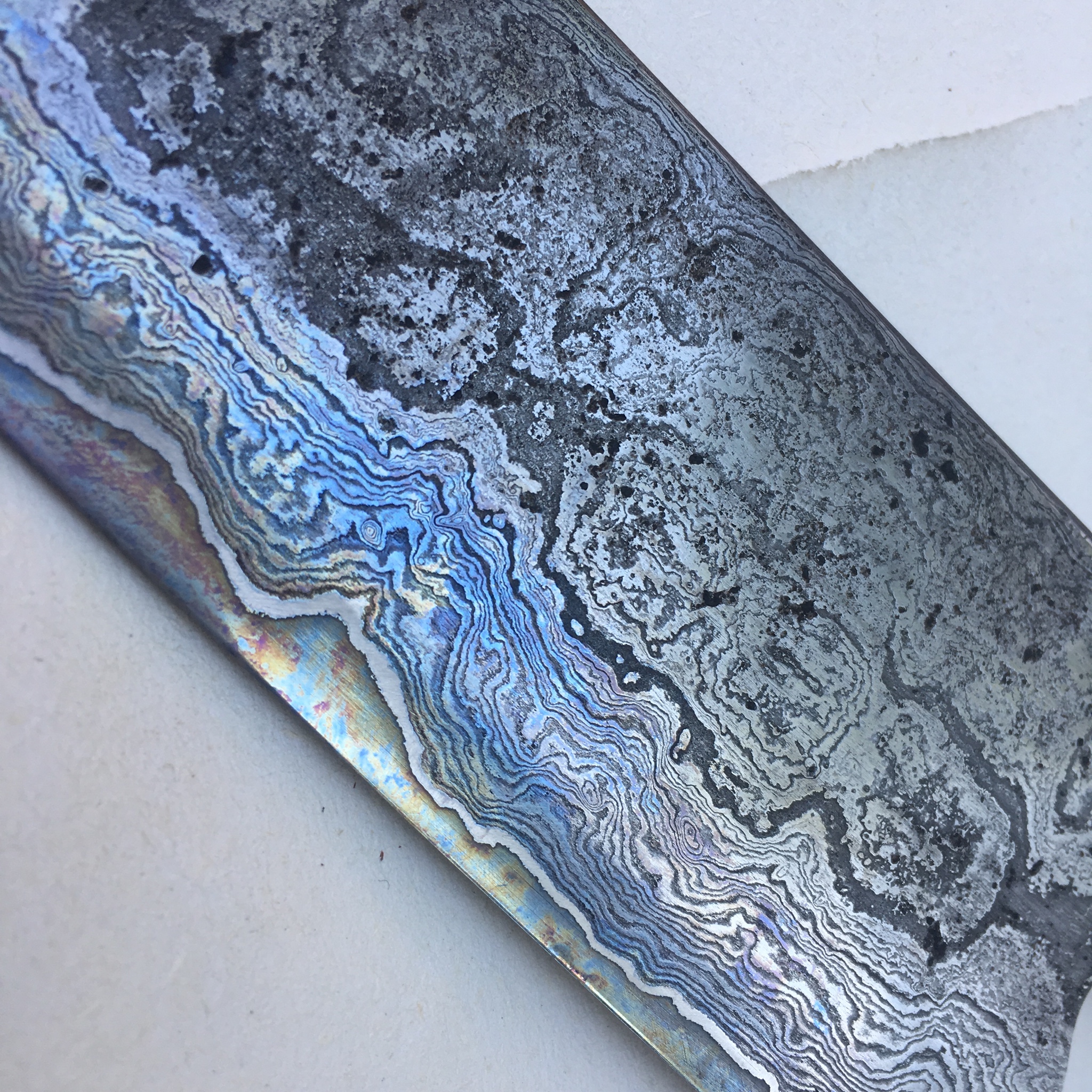

Got some better pics of it in daylight, the steel has started to take a nice blue patina from dicing a couple of kilos of chicken ! The blade is pretty smooth, although the pics make the topography of the blade look like the alps !

Agreed! Those profiles look nice as-forged; I imagine they'll be great once ground in....they look 'honest' as forged I think.

Looks awesome!

Im pretty happy with the composition of the metal on this one! shown in the 'as forged' pics above.

+1 !Looks awesome!

Enter your email address to join: