HRC_64

Senior Member

- Joined

- Aug 8, 2017

- Messages

- 2,714

- Reaction score

- 595

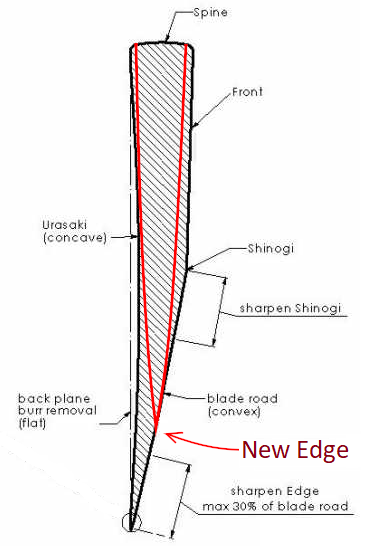

I think its oversimple to think a couple strokes will turn a scandi V into a "convex" edge.

A real convex edge has metal where the V has already removed it, so "taking more metal away"

by blending V facets doesn't correct this problem...

Hope this makes sense, but this is why the mouspad etc work...

you neve get the V to start with that way...you have real convex.

Similar as you would never say a clamshell-sharpened double bevel (or single bevel),

is a "convex" grind in general (and not a wide bevel variation, etc)

the edge rolling style works also, though similarly... it helps to not over flatten ("V") the edge

before you start applying the method.

just my $0.02

A real convex edge has metal where the V has already removed it, so "taking more metal away"

by blending V facets doesn't correct this problem...

Hope this makes sense, but this is why the mouspad etc work...

you neve get the V to start with that way...you have real convex.

Similar as you would never say a clamshell-sharpened double bevel (or single bevel),

is a "convex" grind in general (and not a wide bevel variation, etc)

the edge rolling style works also, though similarly... it helps to not over flatten ("V") the edge

before you start applying the method.

just my $0.02