DitmasPork

Senior Member

It's been a bad winter with me and wooden things.

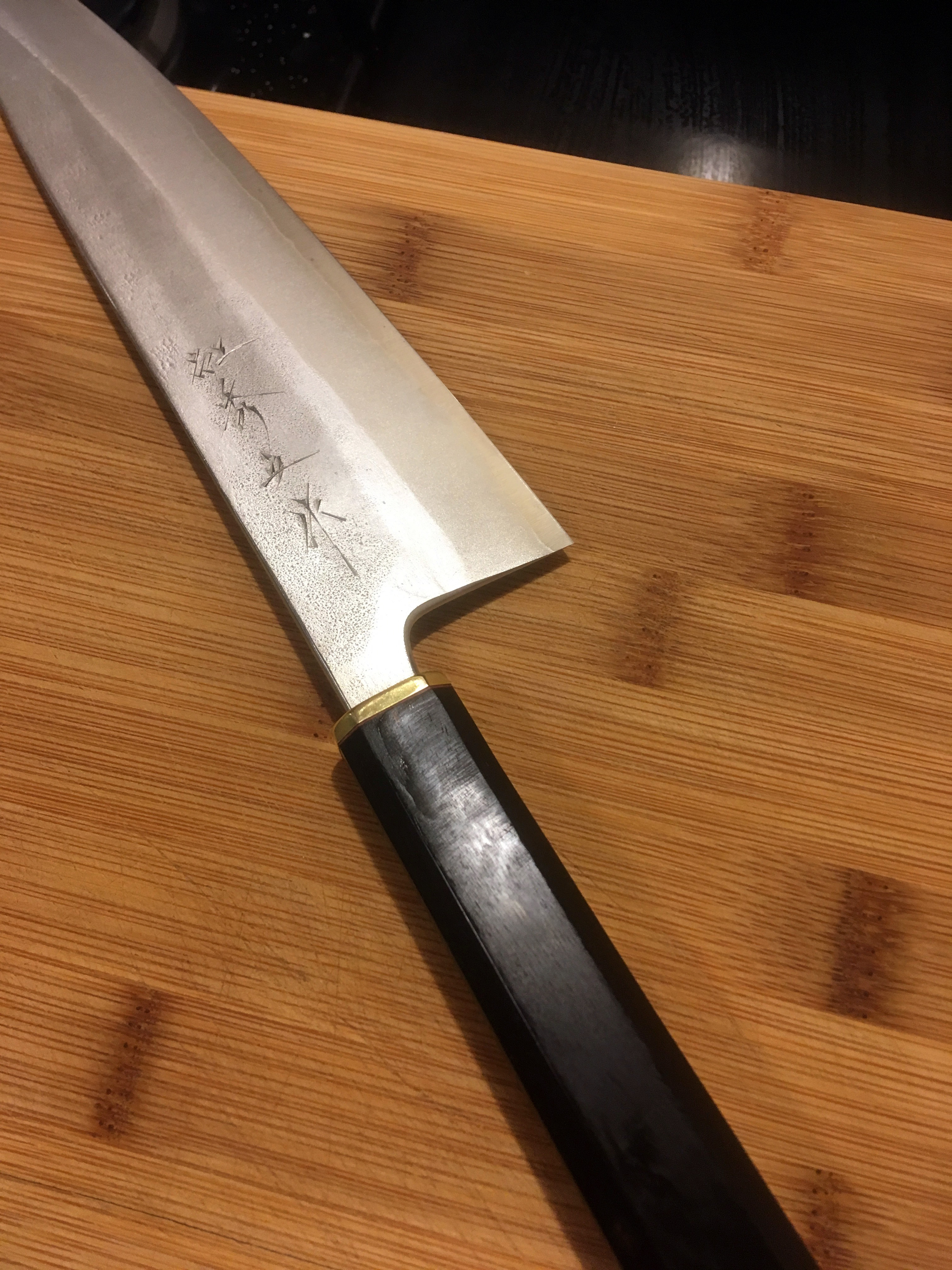

First my Tanaka ebony handle cracked near the ferrule—I'm fixing it now by filling the crack with Krazy Glue, drying now.

Yesterday I was very bummed out to find two significant cracks on my beloved BoardSmith! Urgh! It's an end-grain maple, 14 x 20 x 2, which I've had for nearly 8 years, oiling it regularly.

Question is:

• Does my cutting board need to be repaired by a professional woodworker, or is the crack likely to close up once the weather gets more normal? I'm an urban dweller without much wood knowledge. I've no idea what woodworkers charge.

• Is it beyond saving—should I just write it off and as a lost cause and be happy that I had 8 wonderful years with it?

• Since I don't have clamps or a workbench, can I just fill it with some sort of food-safe putty (is there such a product?)?

Would appreciate feedback from anyone whose had a cracked board and how they dealt with it.

First my Tanaka ebony handle cracked near the ferrule—I'm fixing it now by filling the crack with Krazy Glue, drying now.

Yesterday I was very bummed out to find two significant cracks on my beloved BoardSmith! Urgh! It's an end-grain maple, 14 x 20 x 2, which I've had for nearly 8 years, oiling it regularly.

Question is:

• Does my cutting board need to be repaired by a professional woodworker, or is the crack likely to close up once the weather gets more normal? I'm an urban dweller without much wood knowledge. I've no idea what woodworkers charge.

• Is it beyond saving—should I just write it off and as a lost cause and be happy that I had 8 wonderful years with it?

• Since I don't have clamps or a workbench, can I just fill it with some sort of food-safe putty (is there such a product?)?

Would appreciate feedback from anyone whose had a cracked board and how they dealt with it.