Hi all,

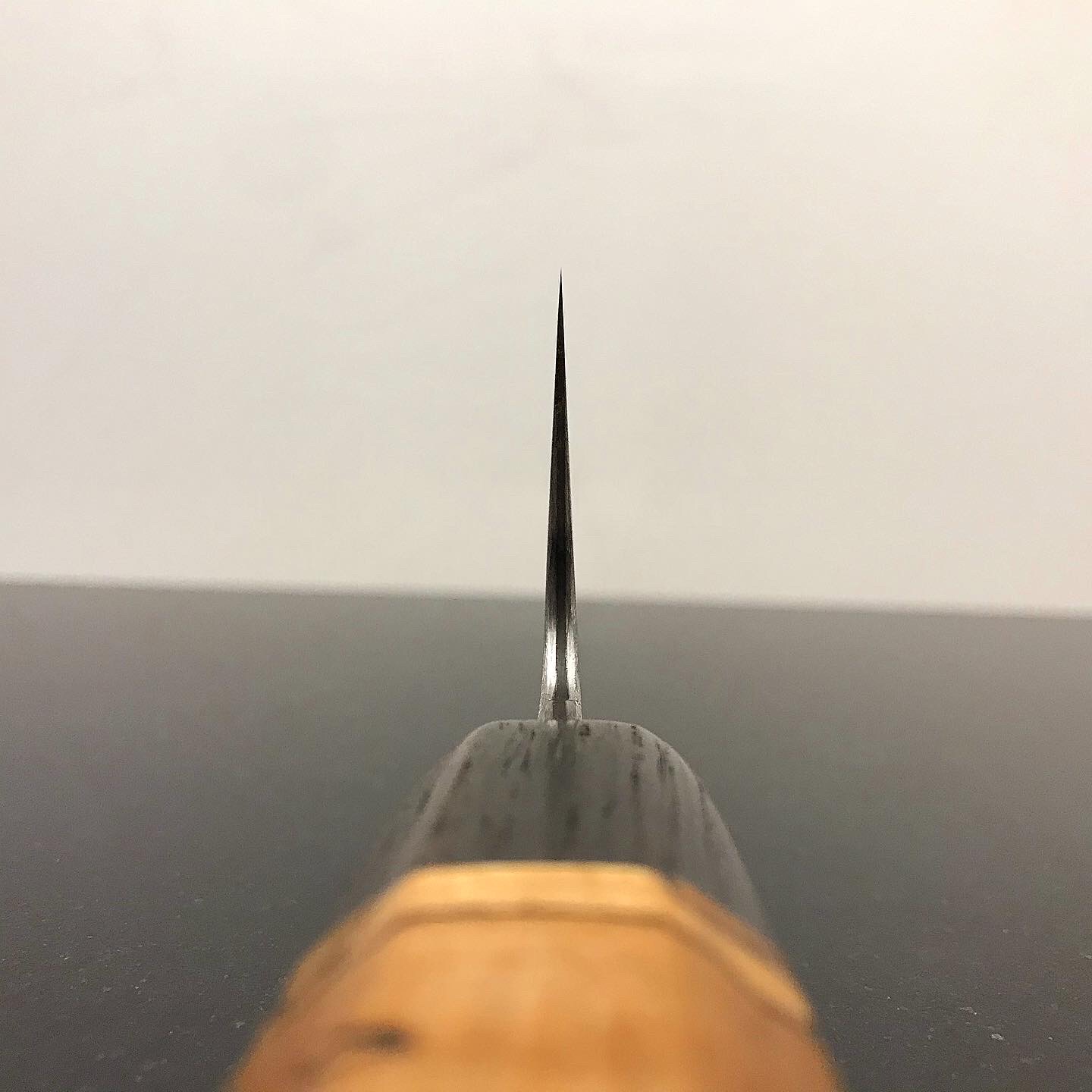

this may be a REALLY dumb Q, when grinding the blade how thick do you leave the edge before sharpening. Seems wrong to grind all the way so the 2 planes meet. Have ground it down to 0.4mm/0.1575″ and am not sure whether to reduce further. Any pointers would really help.

Pic to follow cos that ^ may not make sense

this may be a REALLY dumb Q, when grinding the blade how thick do you leave the edge before sharpening. Seems wrong to grind all the way so the 2 planes meet. Have ground it down to 0.4mm/0.1575″ and am not sure whether to reduce further. Any pointers would really help.

Pic to follow cos that ^ may not make sense