- Joined

- Jan 16, 2016

- Messages

- 492

- Reaction score

- 60

On all my san mai knives, where the cladding meets the core, is a normal, clean boundary, which when polished exaggerates the difference between the two. Normal and fine and whatever.

Now, on my Heiji, it's a little different, and I'm not sure why...

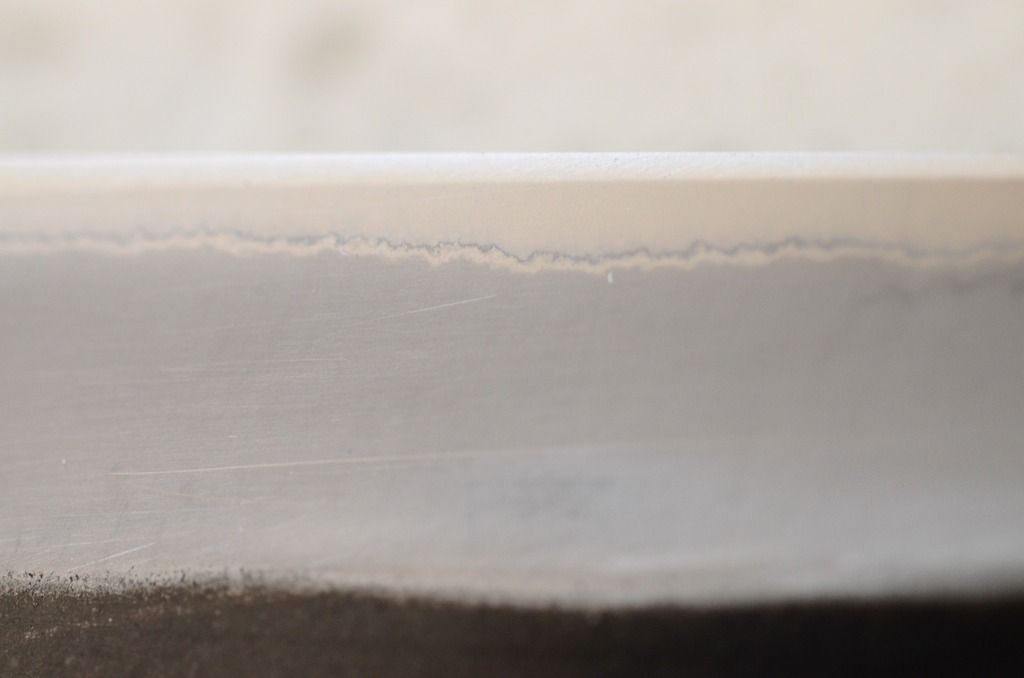

There is the tonal difference, as expected, between the more mirrored and shiny iwasaki core, and the darker cloudier cladding. But there is also a physical 'line', as if someone has drawn with a super fine pencil this boundary on the knife. This alone poses a question why on some knives there is this 'line' and on some just a smooth boundary. But here it gets more confusing to me, as this 'line' on my heiji, is about 1mm below the 'tonal' cladding line - so for 1mm above this line, it is still mirror and shiny, before you hit the kasumi cladding.

I've had this knife for about a year and always wondered, but never asked...

I know this thread is completely and utterly, annoyingly useless without pics, but I just can't capture it on my ****** phone, will try and get some pics up later if I can. But someone probably knows what I'm on about without them, maybe.

Now, on my Heiji, it's a little different, and I'm not sure why...

There is the tonal difference, as expected, between the more mirrored and shiny iwasaki core, and the darker cloudier cladding. But there is also a physical 'line', as if someone has drawn with a super fine pencil this boundary on the knife. This alone poses a question why on some knives there is this 'line' and on some just a smooth boundary. But here it gets more confusing to me, as this 'line' on my heiji, is about 1mm below the 'tonal' cladding line - so for 1mm above this line, it is still mirror and shiny, before you hit the kasumi cladding.

I've had this knife for about a year and always wondered, but never asked...

I know this thread is completely and utterly, annoyingly useless without pics, but I just can't capture it on my ****** phone, will try and get some pics up later if I can. But someone probably knows what I'm on about without them, maybe.