Hey everyone,

Almost every instructional video I’ve seen with plunge lines or wa handles, the knife maker uses a file guide to get those lines perfect or to get that step to the machi perfect (I think that’s what it’s called).

I don’t think I’ll be grinding plunge lines.. but I’ll definitely be learning to make wa handles. As I’m getting closer to setting up shop, I’ve gathered almost everything on my supplies list. A file guide is one thing I’ve been debating.

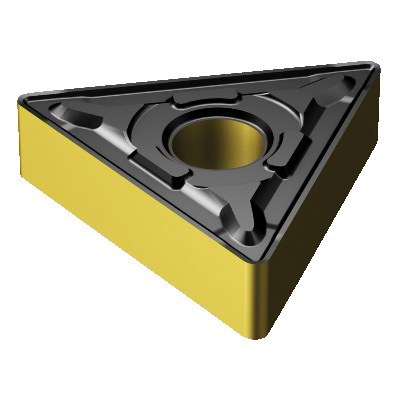

They seem pretty expensive to order if you go with a carbide surface. And also a little pricey to order materials to make one.

So I guess my question is.. do you all use file guides? Or is there another way to achieve the same result? Like using hardened scrap steel maybe?

Almost every instructional video I’ve seen with plunge lines or wa handles, the knife maker uses a file guide to get those lines perfect or to get that step to the machi perfect (I think that’s what it’s called).

I don’t think I’ll be grinding plunge lines.. but I’ll definitely be learning to make wa handles. As I’m getting closer to setting up shop, I’ve gathered almost everything on my supplies list. A file guide is one thing I’ve been debating.

They seem pretty expensive to order if you go with a carbide surface. And also a little pricey to order materials to make one.

So I guess my question is.. do you all use file guides? Or is there another way to achieve the same result? Like using hardened scrap steel maybe?