ForeverLearning

Well-Known Member

I am looking at a few used treadmills to get a scrap motor.

So far there is a range of 0.8HP to 3HP DC motors.

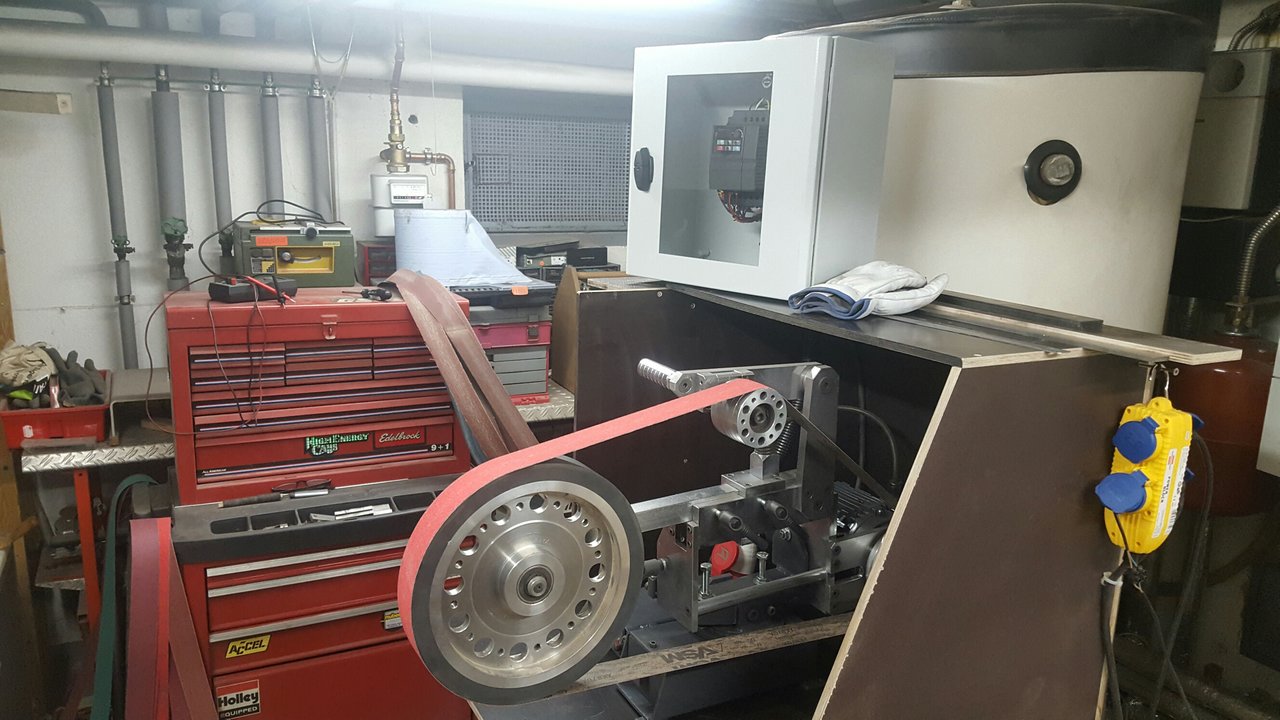

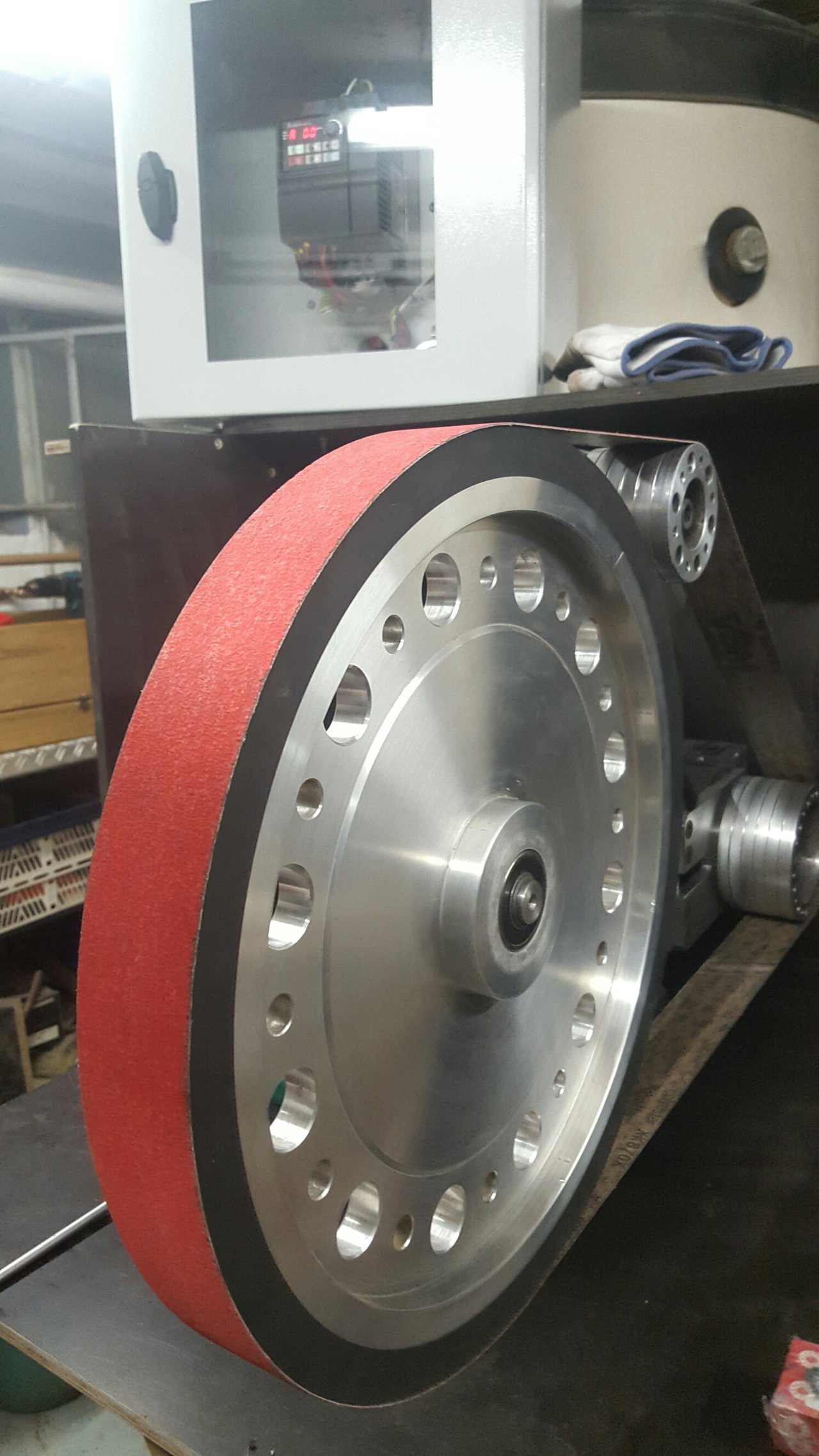

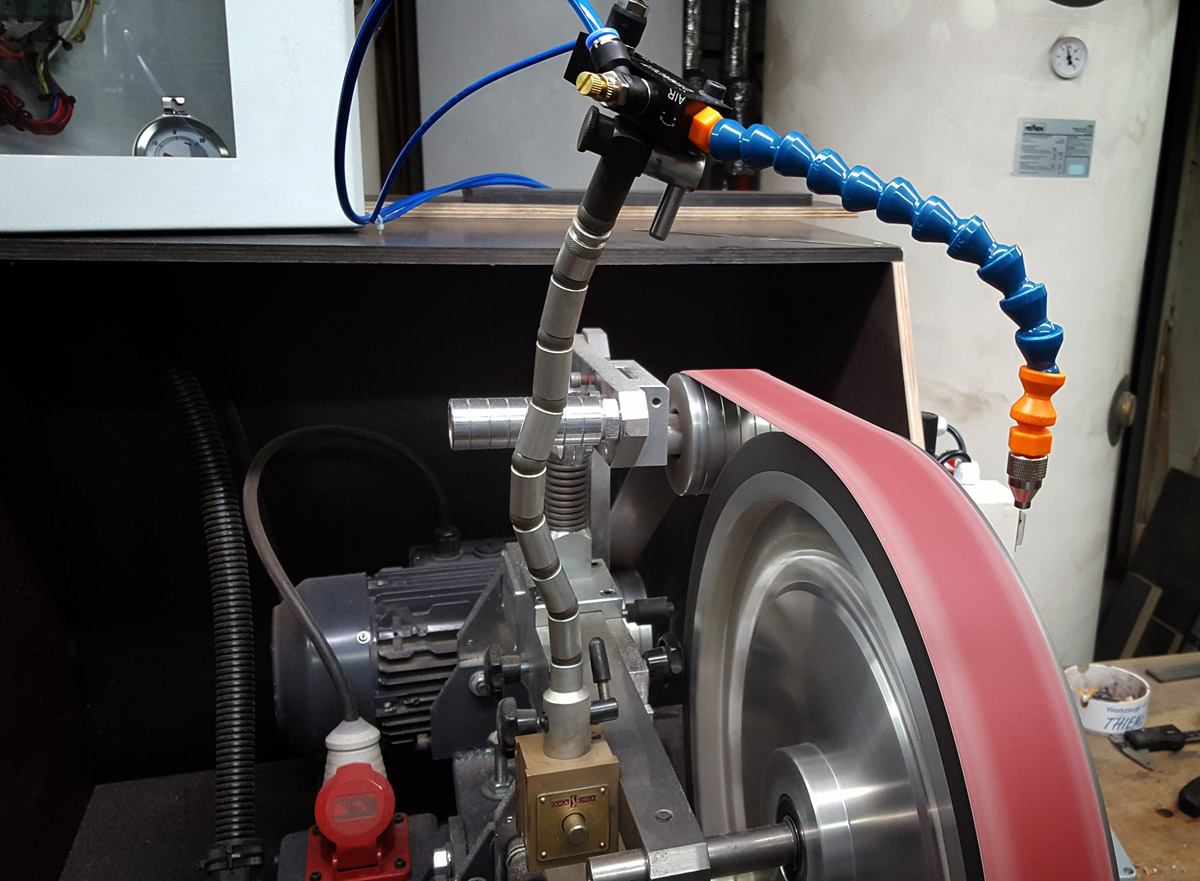

Would anything within this range be suitable for a a 10-12" disk sander build or a 2x72" build?

Cheers!

So far there is a range of 0.8HP to 3HP DC motors.

Would anything within this range be suitable for a a 10-12" disk sander build or a 2x72" build?

Cheers!