Hey,

so after finally deciding on which knife to buy and getting a grasp of everything, my current goal is to be fluent with knife terminology.

However, I feel like I'm stuck a bit and would like to be sure I got things right!

Please let me know if everything is correct.

Does this mean you count Micro bevels or not?

Now for my specific case: this Yoshikane 240

When I first looked at it, it seemed like it wasn't quite 50/50. After tracing it out and checking online again, it should be 50/50 grind. Is this correct?

Furthermore, what am I supposed to sharpen this to? Right now, is it a full flat grind?

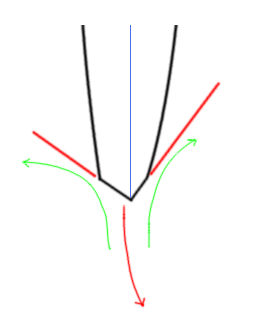

So this would be the optimal geometry, without a tertiary bevel? (red = micro, black = secondary, yellow-ish = Face)

Thanks for helping!

When I'm sure everything is correct, I'll edit/add any missing information and re-upload it.

Thanks!

so after finally deciding on which knife to buy and getting a grasp of everything, my current goal is to be fluent with knife terminology.

However, I feel like I'm stuck a bit and would like to be sure I got things right!

Please let me know if everything is correct.

[aname=microbevel]Microbevel[/aname] – A bevel that is very small, and never the primary bevel.

Don't these contradict eachother? (with question marks in graphic)[aname=primarybevel]Primary Bevel[/aname] – The bevel that makes up the cutting edge. A primary bevel is sometimes a microbevel.

Does this mean you count Micro bevels or not?

Now for my specific case: this Yoshikane 240

When I first looked at it, it seemed like it wasn't quite 50/50. After tracing it out and checking online again, it should be 50/50 grind. Is this correct?

Furthermore, what am I supposed to sharpen this to? Right now, is it a full flat grind?

So this would be the optimal geometry, without a tertiary bevel? (red = micro, black = secondary, yellow-ish = Face)

Thanks for helping!

When I'm sure everything is correct, I'll edit/add any missing information and re-upload it.

Thanks!