I have been watching knifemaking videos on youtube and the large water cooled grinding wheels common to many shops have me curious. Most look like wagon wheels with abrasive tires. Does anyone know how they are constructed? Are the abrasives indeed wheels or are they pieced together in segments?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Large Japanese grinding wheel construction.

- Thread starter bennypapa

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 8, 2014

- Messages

- 624

- Reaction score

- 439

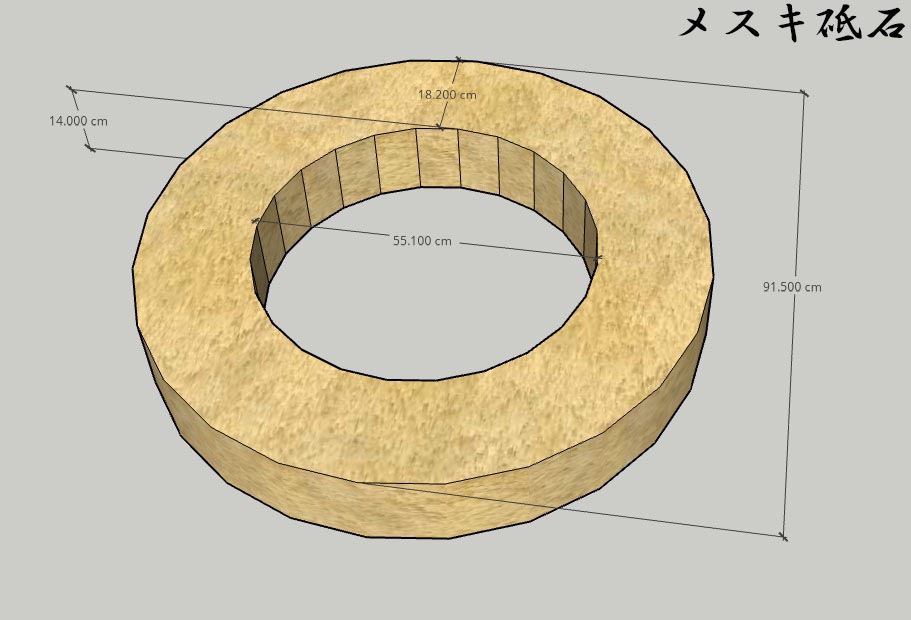

Cement ceramic or resin bonded stone wheels. There are different types and each usually weigh 150kgs.

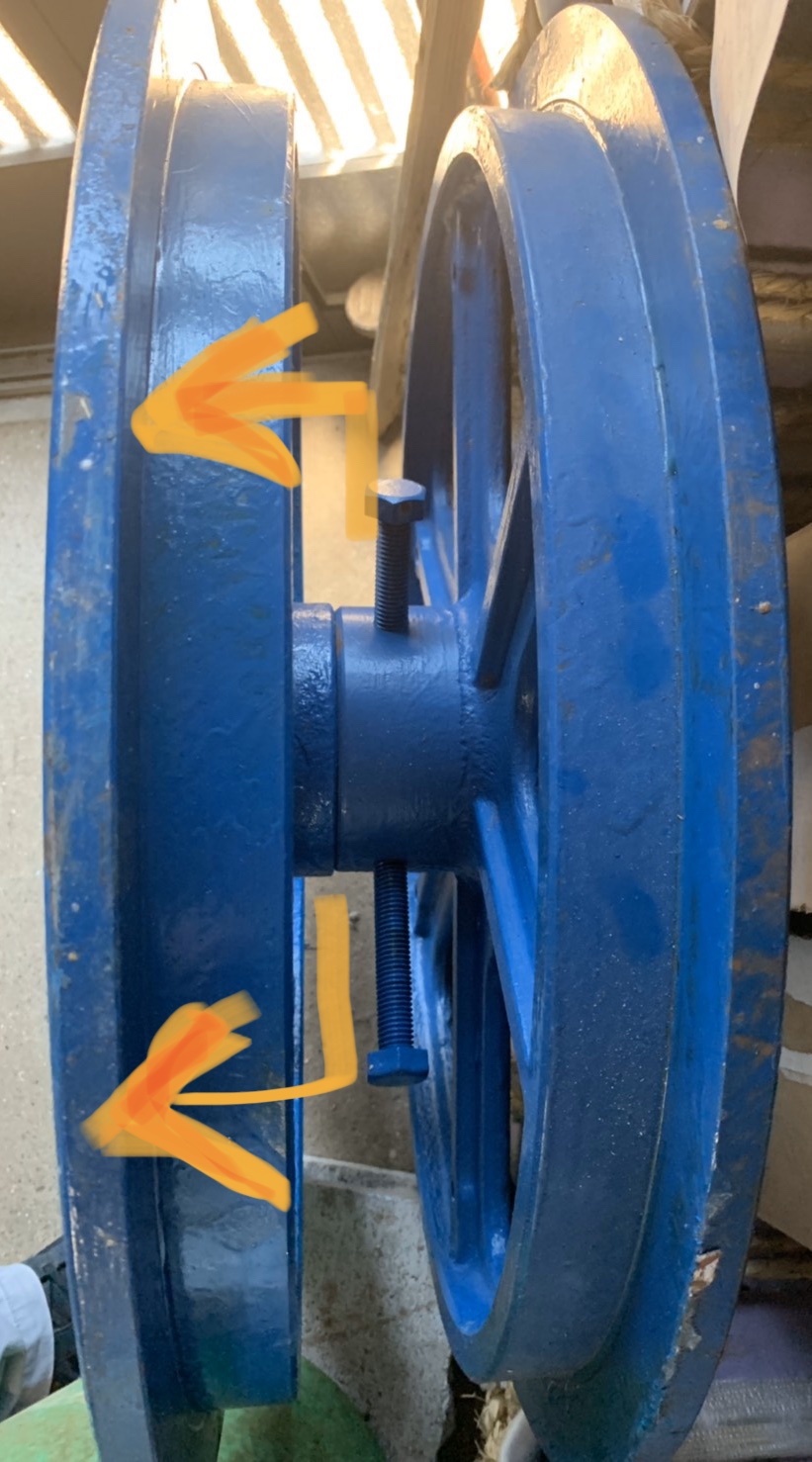

They will be set into a shaft and wheel clamp. That then gets set onto a tank and machine that spins it.

They do not look like tires brand new. They are smooth. The hash markings come from hammering or cutting into the stone to create grooves in order for the stone to grip and remove steel. If the stone is smooth it will tact just like a smooth tire on water road, will slip.

They will be set into a shaft and wheel clamp. That then gets set onto a tank and machine that spins it.

They do not look like tires brand new. They are smooth. The hash markings come from hammering or cutting into the stone to create grooves in order for the stone to grip and remove steel. If the stone is smooth it will tact just like a smooth tire on water road, will slip.

- Joined

- Jul 8, 2014

- Messages

- 624

- Reaction score

- 439

Comes off for the stone to be placed on and then clamped in again.

Yes it’s one giant round stone, just like a wheel