You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Laser gyuto in pro kitchens

- Thread starter Cksnffr

- Start date

Help Support Kitchen Knife Forums:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Does anyone actually use a "laser" gyuto at work? In your experience, are they common pro tools or more like newbie catnip?

Yes. I prefer to. I bought one and never looked back. IMO if you get the right one they're just better in every way. I can see how using a harder laser might be a problem. I used a Takayuki TUS stainless and loved it. Pretty sure its like 1.7-1.8mm at the spine. Its was tough as hell so I didn't need to baby it. Ootb 70/30 edge was excellent and it held for a long time considering how soft the steel was. I was a soup cook so I was cutting veg all day long including lots of butternut. Would recommend.

As far as being labeled a noob, I've been called one by a wusthof user who thought I was dumb for using japanese knives at all. He said the only japanese knife he would ever use is a Shun...

- Joined

- Dec 15, 2011

- Messages

- 11,235

- Reaction score

- 7,507

This is quite funny.As far as being labeled a noob, I've been called one by a wusthof user who thought I was dumb for using japanese knives at all. He said the only japanese knife he would ever use is a Shun...

Kippington

A small green parrot

This thread is making realise there'd probably be a lot of love out there for thin grinds, but with thicker spines near the handle.

If I had a power hammer, I could smash these out so cheap and fast...

If I had a power hammer, I could smash these out so cheap and fast...

I’ll contribute to the kippington gofundme.This thread is making realise there'd probably be a lot of love out there for thin grinds, but with thicker spines near the handle.

If I had a power hammer, I could smash these out so cheap and fast...

Kippington

A small green parrot

Nah don't bother. There's more that goes into a power hammer than you might think.I’ll contribute to the kippington gofundme.

- New workspace outta the 'burbs

- Reinforced floor

- Appropriate forge

- Power-hammer

- $$$

This thread is making realise there'd probably be a lot of love out there for thin grinds, but with thicker spines near the handle.

If I had a power hammer, I could smash these out so cheap and fast...

I think softer, tougher steels need to make a comeback. Just because a knife isn't 75hrc doesn't mean it's a bad knife. I'd have no problem hammering in a nail with the back of my 1.7mm spine on my stainless laser.

Okay I'd have a few problems, but I wouldn't be worried about my blade breaking off.

tostadas

Hobbyist / Craftsman

Nah don't bother. There's more that goes into a power hammer than you might think.

- New workspace outta the 'burbs

- Reinforced floor

- Appropriate forge

- Power-hammer

- $$$

Sounds simple enough.

- Joined

- Dec 15, 2011

- Messages

- 11,235

- Reaction score

- 7,507

I definitely agreeI think softer, tougher steels need to make a comeback. Just because a knife isn't 75hrc doesn't mean it's a bad knife. I'd have no problem hammering in a nail with the back of my 1.7mm spine on my stainless laser.

Okay I'd have a few problems, but I wouldn't be worried about my blade breaking off.

Kippington

A small green parrot

Well it's all relative. I mean, there's a good reason why it all exists on a scale. Wear resistant lasers are pretty awesome, but also the ease of sharpening a 60-62 HRC laser cannot be ignored.I think softer, tougher steels need to make a comeback. Just because a knife isn't 75hrc doesn't mean it's a bad knife. I'd have no problem hammering in a nail with the back of my 1.7mm spine on my stainless laser.

As for toughness, it almost dictates the thinness behind the edge of a laser. Knowing what the knife will be used for and how tough it is, and you can get away with some crazy thin edges if you are happy to make some compromises.

Even if this knife was softer and tougher than a factory VG-10 blade, someone with poor understanding of strength and toughness would chip/deform this edge and call the steel worse than any Shun they've ever used.

I can imagine it getting absolutely wrecked by someone doing this heavy-handedly, thinking it's completely normal for every knife to withstand...

Last edited:

HRC_64

Senior Member

- Joined

- Aug 8, 2017

- Messages

- 2,714

- Reaction score

- 595

I feel like lasers (and probably other knives very thin TBE) are just slightly more wear-prone...But also they sharpen up so easily...can't even imagine you save more than 0.3 of a second using a steel vs touching up a laser on a 3 or 4k. Not everyone at work has the luxury of whipping out a (pre-soaked, etc) stone, tho.

it is way more convenient and faster to take out a mac black out of the knife roll than to go through the touchup process. a few swipes before shift and after shift is all a knife with a workable edge needs.I feel like lasers (and probably other knives very thin TBE) are just slightly more wear-prone...But also they sharpen up so easily...can't even imagine you save more than 0.3 of a second using a steel vs touching up a laser on a 3 or 4k. Not everyone at work has the luxury of whipping out a (pre-soaked, etc) stone, tho.

- Joined

- Jun 7, 2018

- Messages

- 334

- Reaction score

- 321

Nah don't bother. There's more that goes into a power hammer than you might think.

- New workspace outta the 'burbs

- Reinforced floor

- Appropriate forge

- Power-hammer

- $$$

Seems a bit excessive to reinforce the floor....

As for toughness, it almost dictates the thinness behind the edge of a laser.Interesting. I'm a bit confused by what you're trying to say. I'm pretty new to the deep science behind it all. What is it specifically that someone with little knowledge should know? Are you saying that a thinner knife, even of it is tougher is more prone to chopping than a thicker harder knife? Genuine question. I'm interested in learning more about this kind of stuff and how toughness and thickness correlate.

Last edited:

This thread is making realise there'd probably be a lot of love out there for thin grinds, but with thicker spines near the handle.

If I had a power hammer, I could smash these out so cheap and fast...

I'm a fan, for sure. That's what I ended up doing with this Wat 180 gyuto I was working on. Super aggressive taper from the handle to the middle of the blade. Feels comfortable in the hand for sure, and cuts like a dream. (Not that my idiotic attempts at knife-modifying are in any way comparable to anything professional.)

Seems a bit excessive to reinforce the floor....

That is the cutest power hammer I've ever seen. Btw, @Kippington, how much noise do you make and how do you try to prevent it from leaking out? Does most of the noise come from hammering, or grinding? I have these unrealistic dreams of eventually having a knife making setup in my backyard, which will hopefully be in the burbs as opposed to my current location in the city, and am wondering how realistic it’ll be to not piss off everyone on my block.

Interesting. I'm a bit confused by what you're trying to say. I'm pretty new to the deep science behind it all. What is it specifically that someone with little knowledge should know? Are you saying that a thinner knife, even of it is tougher is more prone to chopping than a thicker harder knife? Genuine question. I'm interested in learning more about this kind of stuff and how toughness and thickness correlate.

Thinner = more fragile

Harder = more chippy, less "tough" (but also less bendy)

So the true toughness of a knife is some function of both variables. I think Kip was just saying that people unused to a thin knife might expect it to be tougher than it is, and use it in ways it shouldn't be used. (And then they might blame it on the steel instead of the geometry.) But if the user is willing to be careful, you can get away with a super thin edge.

Last edited:

Keith Sinclair

Senior Member

One of the only negatives of a laser in a pro kitchen is they wear down faster. Much less steel. That's why important to keep an even bevel heel to tip so you still have a smooth blade geometry even after steel has been taken off the knife over the years. I know from experience have put bird beaks on thin tips in the past

Kippington

A small green parrot

Yep.Are you saying that a thinner knife, even of it is tougher is more prone to chipping than a thicker harder knife?

Okay, you seem to have a good idea of hardness and toughness. What we're getting into here is another thing: strength.

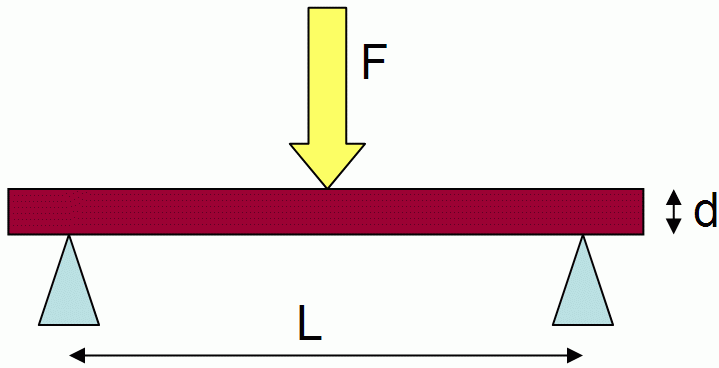

Strength is about the behaviour of solid objects under stresses and strains. Lets say you have two pieces of 52100 steel rod (rod A and rod B). Both of them have been heat-treated the exact same, but rod B has a quarter of the diameter of rod A. Because they are made from the same material and have the same HT, they'll have the same hardness and toughness, but the piece with a smaller diameter will have less strength. For example:

Let's support both ends of rod A and apply an amount of force to the middle of the rod, enough to have it elastically deform. This means that there's enough force to make the rod bend out of shape, but once the force is removed, the rod will return back to it's original shape.

Let's take rod B and attempt the same thing. At a quarter of the diameter, there is not enough flexural strength to take the same amount of force, and the rod will fail to maintain it's shape - either by cracking if the toughness is low, or plastic deformation (remaining bent out of shape once the force is removed) if the toughness is high.

With knife steels, we want the the material strength to be as high as we can get it. So in the heat treatment we aim to get the steel to be as hard as we can to stop plastic deformation, while also keeping a good level of toughness to stop cracking. On knives, once we begin to push how thin we make the cross sections, the strength of the edge decreases as we go thinner, and the benefits of the steel's toughness begins to outweigh the importance of its hardness (although that's not to say that the hardness is no longer important). A good analogy would be to think of the amount of care you would need to carry a piece of A4 paper around for a day without creasing it (or cracking it

All of this needs to be taken into consideration when grinding a super thin laser. A thicker edge has more strength (think of a thick sheet of glass), so we can feel safer with less toughness and start pushing the HT towards the side of hardness. On a thin knife with lesser strength (think of a thin sheet of glass), it's better if we aim on the side of higher toughness. A tiny bend in the steel is nowhere near as bad as a sudden crack.

It's worth remembering that, at a given hardness, some steels will have a higher toughness than others. These same tougher steels also generally have lower wear resistance/scratch hardness.

Here's an example of a knife made to be thin and easy to elastically deform, while also attempting to balance it with high hardness. A tougher steel or HT would've allowed it to bend or 'take a set' (plastic deformation) instead of snapping.

I see this "bird beak" effect get done so often to lasers...That's why important to keep an even bevel heel to tip so you still have a smooth blade geometry even after steel has been taken off the knife over the years. I know from experience have put bird beaks on thin tips in the past

Last edited:

Kippington

A small green parrot

Hammering and grinding are both loud enough to piss the neighbours off. Grinding is more consistent, like the background sound you get while sitting on a plane. Hammering is like the crying baby a few rows back.Btw, @Kippington, how much noise do you make and how do you try to prevent it from leaking out? Does most of the noise come from hammering, or grinding? I have these unrealistic dreams of eventually having a knife making setup in my backyard, which will hopefully be in the burbs as opposed to my current location in the city, and am wondering how realistic it’ll be to not piss off everyone on my block.

So.... you're saying you need to shake the hammer like a baby that's crying in the back of the airplane?Hammering and grinding are both loud enough to piss the neighbours off. Grinding is more consistent, like the background sound you get while sitting on a plane. Hammering is like the crying baby a few rows back.

Throw it out of the planeSo.... you're saying you need to shake the hammer like a baby that's crying in the back of the airplane?

What good would the hammer be to Kippington then?Throw it out of the plane

i meant the crying baby.What good would the hammer be to Kippington then?

by crying baby i meant me, cause panda love sky diving.

Kippington

A small green parrot

I have found the solution

The have a place for sure. But you need an arsenal. On my pass i have within arms reach: 240 laser gyuto, 150 petty 180 santoku, 300 beater. All getting used pretty evenly.