bennyprofane

Senior Member

- Joined

- May 21, 2016

- Messages

- 585

- Reaction score

- 13

I recently visited an old friend who's a carpenter and we decided to make a magnetic knife strip. We used walnut wood and made a board of 1200x100x20mm and we used 37 Neodym N42 disc magnets 20x10mm. The magnets should be at least twice as thick as the wood which separates them from the knives. There is a 3cm distance between the centres of the magnets. This enables me to put the knife at every point on the strip.

These are the magnets: https://www.supermagnete.de/scheibe...mm-hoehe-10mm-neodym-n42-vernickelt_S-20-10-N

Here are some pictures.

Choosing the wood

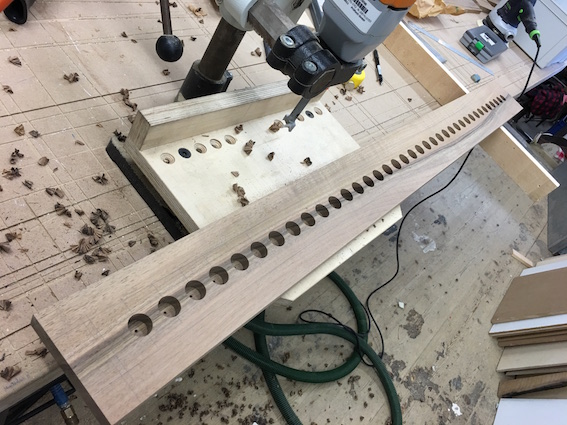

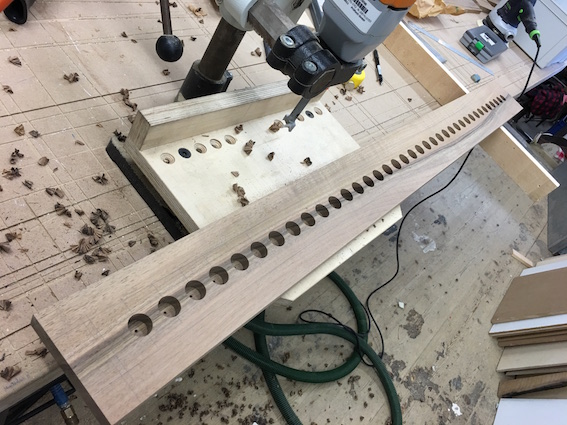

Milling the holes for the magnets

We glued them in with wood glue, one had to cover the previous hole with the thumb as they would jump out.

For drying we stuck the strip to the side of the table, the magnets stuck so hard to that thin steel that it took a lot of force to remove it.

The mounting for hanging it up.

All done.

These are the magnets: https://www.supermagnete.de/scheibe...mm-hoehe-10mm-neodym-n42-vernickelt_S-20-10-N

Here are some pictures.

Choosing the wood

Milling the holes for the magnets

We glued them in with wood glue, one had to cover the previous hole with the thumb as they would jump out.

For drying we stuck the strip to the side of the table, the magnets stuck so hard to that thin steel that it took a lot of force to remove it.

The mounting for hanging it up.

All done.