I have recently worked on a complete re-finish of a lovely 225 Hide Blue #1 gyuto and in the process I needed finger stones for the final finish. Since Maxim did not have any available at the time I have bought from him (OK, actually I got it for free, but that is a different story) Tomo Nagura Extra (should be either Takashima or Ohira accorting to Maxim) what turned out to be a lovely and surprisingly large piece of stone.

Of course - I could not resist to write an article on my blog - so there you can find a lot of details.

I would love to hear your feedback and opinions - I did this for the first time and surely there are things to improve for the next time.

Here a few photos

Nagura and some tools

Flattening pieces of the nagura on JKI diamond plate

After gluing to cotton tissue finishing on JNS 300 and Gesshin Synthetic Natural Stone

Finished finger stone before braking

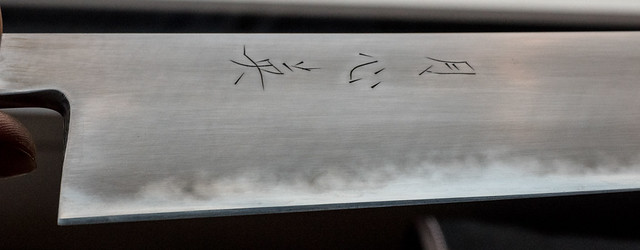

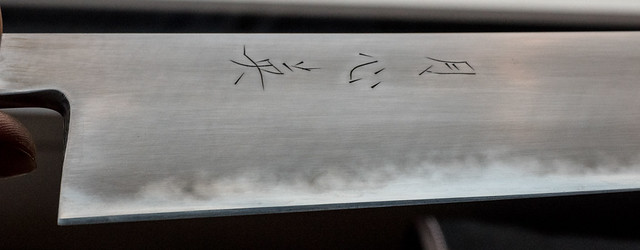

Quick result (with boosted contrast in PP) - looks good (the streaks disappeared later). The blade was finished to #2500 sanding paper before I used the finger stones.

Of course - I could not resist to write an article on my blog - so there you can find a lot of details.

I would love to hear your feedback and opinions - I did this for the first time and surely there are things to improve for the next time.

Here a few photos

Nagura and some tools

Flattening pieces of the nagura on JKI diamond plate

After gluing to cotton tissue finishing on JNS 300 and Gesshin Synthetic Natural Stone

Finished finger stone before braking

Quick result (with boosted contrast in PP) - looks good (the streaks disappeared later). The blade was finished to #2500 sanding paper before I used the finger stones.