zetieum

Senior Member

Hey, I see I miss this post. I am the happy owner of the knife. Matus did and amazing job. now the knife cuts like a dream. Moreover the handle Matus made is absolutely gorgeous and feels very good in the hand. Matus went through a lot to achieve this project and I am extremly grateful. More importantly, the project around this knife made me meet a great guy, led to fruitful exchanges!

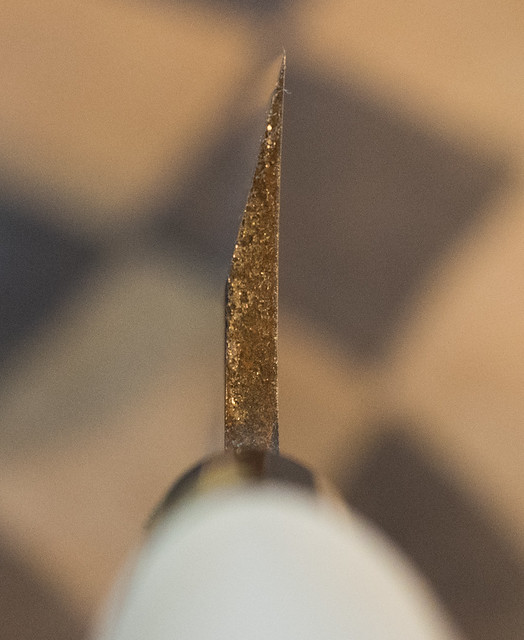

Recently, I sharpened and refinished it. Bevels are perfect and it took no time on the stones. And what a pleasure to polish it to get a nice kasumi. I will share some pic, if i find where they are.

Recently, I sharpened and refinished it. Bevels are perfect and it took no time on the stones. And what a pleasure to polish it to get a nice kasumi. I will share some pic, if i find where they are.