Drayquan

Well-Known Member

- Joined

- May 21, 2018

- Messages

- 68

- Reaction score

- 4

(Sharpening with whetstones for about 3 years now, I've improved a great deal but know I still have a LOT more to learn. I sharpen for myself/family/friends, and in the past year, for neighbors for extra cash now and then. In general, results have been good and everyone's happy.)

So a neighbor just asked me to sharpen their set of Henckels kitchen knives. Most of them needed some thinning/re-profiling, my (newly arrived) chosera 400 was able to take care of that easily before a standard progression to 1k, 4k and 6k finish.

No problem, they turned out beautifully.

Then comes along their cleaver. Holy hell, FML.

It was fairly dull and beaten up but looked totally serviceable; I haven't done many cleavers/choppers in the past, but got decent results on the few I've done.

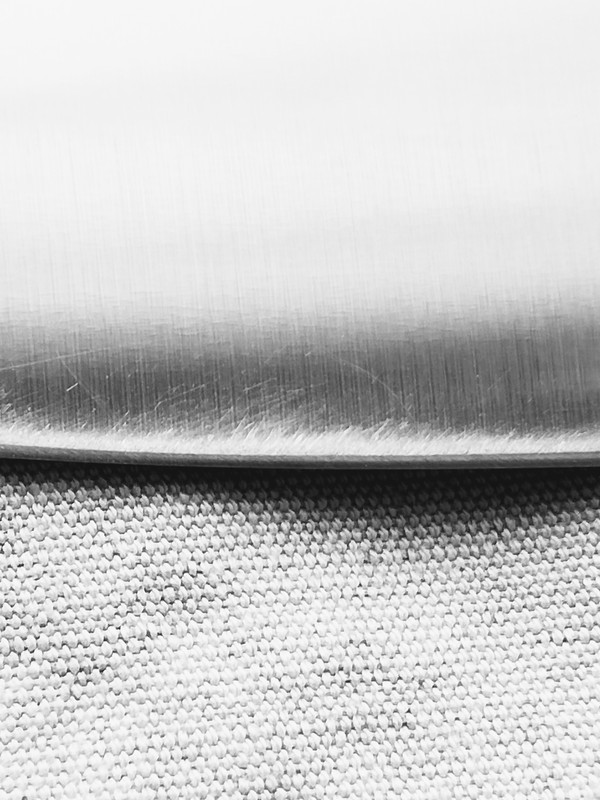

Each side approx a 30° angle (good, keeping that), generally flat but varied with some unevenness/micro valleys here and there. Some tiny micro-chipping along a few inches of the apex, some rough grind marks along the top ridge of the primary bevel from a previous sharpening. These grind marks are deep enough that when removed it would modify the flat grind into a bit more of a convex grind, I assume it'll be a little more work but should turn out nicely.

About 15 minutes in starting on the chosera 400 (applying minimal force when edge leading, a little more force edge trailing), I was noticing almost no change whatsoever on the edge, except for a minor visual surface texture change. 30 minutes total pass, still no real change, so I increase my pressure a bit. 45 minutes total, no burr yet but I've swapped sides a few times since starting to try and keep things even. Sweat starting to drip, 1 hour total, the previous sharpener's grind marks are still there, and the freaking tiny micro edge chipping still hasn't smoothed off. What the hell!?

@ 1hr 30min I finally got an extremely tiny burr, I've smoothed/evened out 90% of the edge surface and established a mostly even arc to the top of the primary bevel, removing some of the old grind marks, but not all. It's not as clean as I'd like, but at this point my chosera 400 is down a few millimeters too many, coughing up so much blood..I mean mud, I figure I've destroyed enough of the stone for today. I have an old worn down cheap budget corundum stone laying around (800grit), I give it some passes and you know what? It seems like its working better than the chosera 400 (maybe its just in my head).

@ 2.5 hours, I say enough grinding. I give it some passes on my primary 1k stone, then some stropping on the 6k which does add a nice aesthetic surface polish. I'm not happy with the edge and overall the cleaver isn't to my service standards, but I call it quits. 3 hours total on one 6" g'damn cleaver, holy hell.

This thing kicked my freaking ass.

I don't know for sure, but I assume a few things:

- My skill with cleavers needs a lot of improvement

- The heat-treat / rockwell hardness was way too high for my specific coarse chosera stone

- Maybe I needed a good coarse diamond plate for this

- A hardcore belt grinder would have far better to start this on

I regret subjecting my chosera 400 to that abuse... sigh

This was cathartic for me, thx kitchen knife forums

So a neighbor just asked me to sharpen their set of Henckels kitchen knives. Most of them needed some thinning/re-profiling, my (newly arrived) chosera 400 was able to take care of that easily before a standard progression to 1k, 4k and 6k finish.

No problem, they turned out beautifully.

Then comes along their cleaver. Holy hell, FML.

It was fairly dull and beaten up but looked totally serviceable; I haven't done many cleavers/choppers in the past, but got decent results on the few I've done.

Each side approx a 30° angle (good, keeping that), generally flat but varied with some unevenness/micro valleys here and there. Some tiny micro-chipping along a few inches of the apex, some rough grind marks along the top ridge of the primary bevel from a previous sharpening. These grind marks are deep enough that when removed it would modify the flat grind into a bit more of a convex grind, I assume it'll be a little more work but should turn out nicely.

About 15 minutes in starting on the chosera 400 (applying minimal force when edge leading, a little more force edge trailing), I was noticing almost no change whatsoever on the edge, except for a minor visual surface texture change. 30 minutes total pass, still no real change, so I increase my pressure a bit. 45 minutes total, no burr yet but I've swapped sides a few times since starting to try and keep things even. Sweat starting to drip, 1 hour total, the previous sharpener's grind marks are still there, and the freaking tiny micro edge chipping still hasn't smoothed off. What the hell!?

@ 1hr 30min I finally got an extremely tiny burr, I've smoothed/evened out 90% of the edge surface and established a mostly even arc to the top of the primary bevel, removing some of the old grind marks, but not all. It's not as clean as I'd like, but at this point my chosera 400 is down a few millimeters too many, coughing up so much blood..I mean mud, I figure I've destroyed enough of the stone for today. I have an old worn down cheap budget corundum stone laying around (800grit), I give it some passes and you know what? It seems like its working better than the chosera 400 (maybe its just in my head).

@ 2.5 hours, I say enough grinding. I give it some passes on my primary 1k stone, then some stropping on the 6k which does add a nice aesthetic surface polish. I'm not happy with the edge and overall the cleaver isn't to my service standards, but I call it quits. 3 hours total on one 6" g'damn cleaver, holy hell.

This thing kicked my freaking ass.

I don't know for sure, but I assume a few things:

- My skill with cleavers needs a lot of improvement

- The heat-treat / rockwell hardness was way too high for my specific coarse chosera stone

- Maybe I needed a good coarse diamond plate for this

- A hardcore belt grinder would have far better to start this on

I regret subjecting my chosera 400 to that abuse... sigh

This was cathartic for me, thx kitchen knife forums