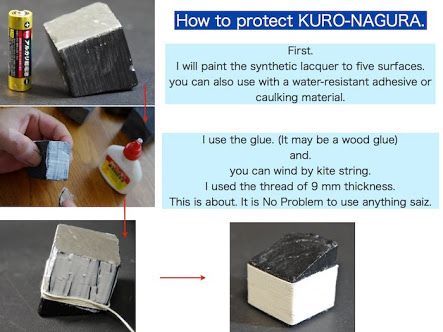

Figured I'd bump this instead of starting a new thread... I have an ocean-mined Tsushima coming my way, and I'm more concerned about long term stability than I'd be for a regular stone. Here are a few interesting solutions I've found elsewhere online:

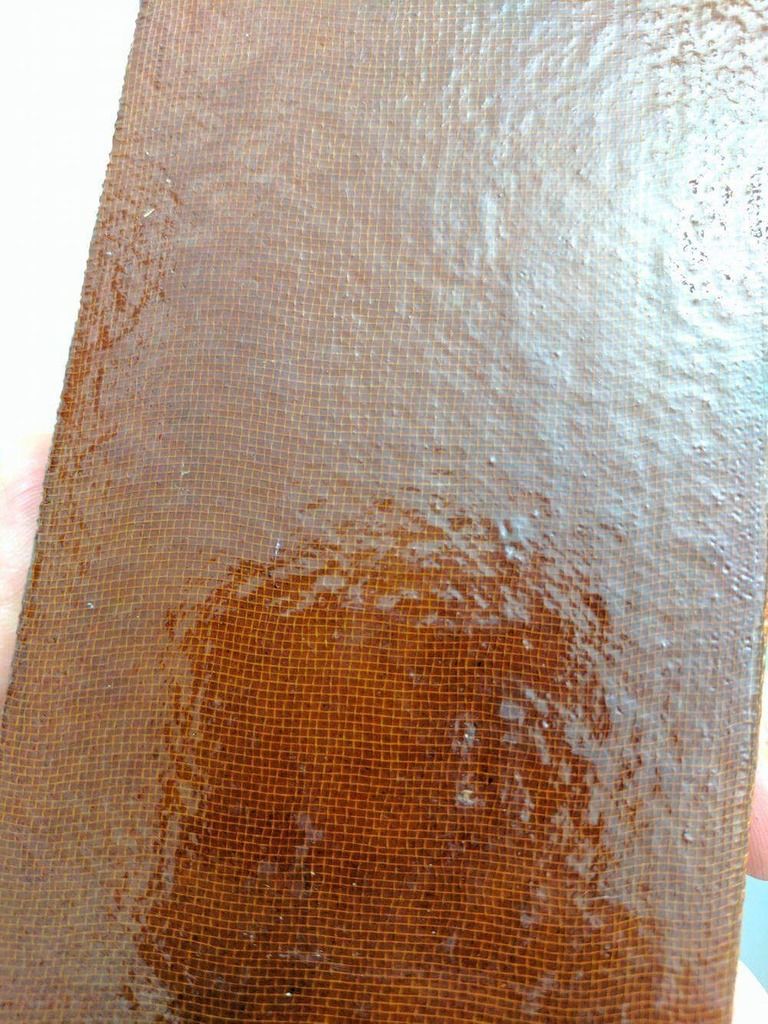

View attachment 97500

Washi paper with unknown lacquer, found here -

Protecting Natural Sharpening Stones

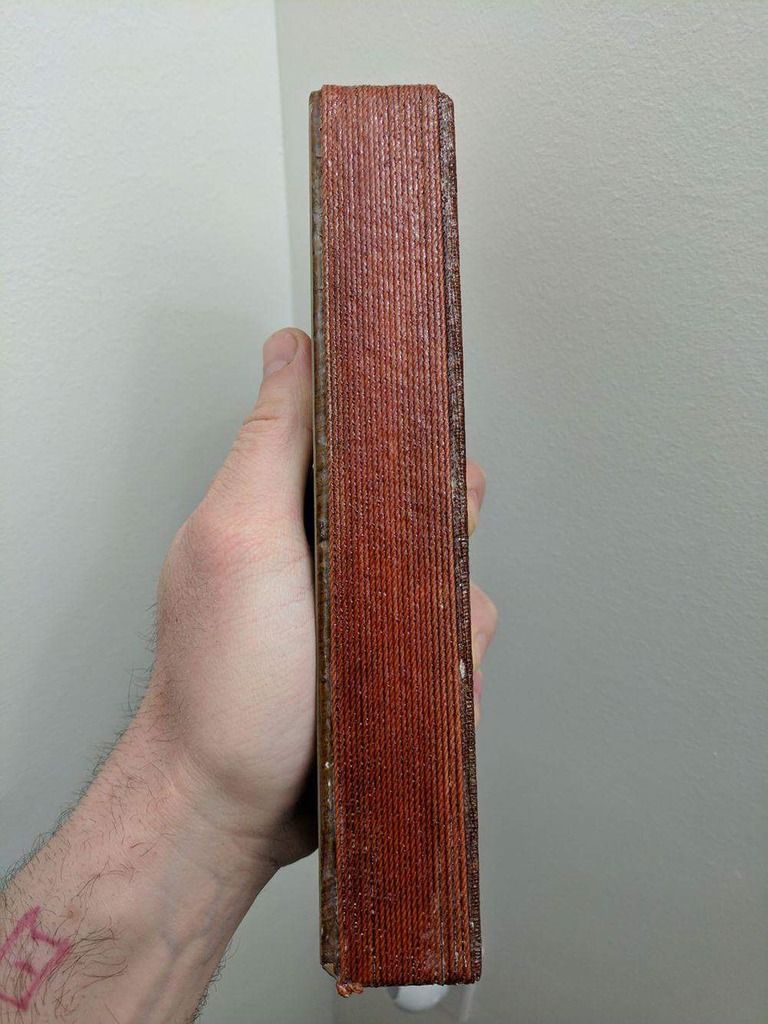

View attachment 97501

Linen bookbinding cloth (can be called mull, crash, or tarlatan) with cashew lacquer, found here -

砥石と研ぎ用具 | アーティスト小林健二の道具や技法

Doing some research it seems this is still an area without much information unfortunately. I have a few questions I haven't been able to find answers to:

- When using washi, is it standard practice to wrap around the stone's edges, or cut individual pieces for each side similar to the example above? Could be mostly decorative, or maybe wrapping the edges is unnecessary and worse for longevity due to wear and potential fraying.

- In theory, is it better to have the larger surface area of the washi, or the higher strength of cloth mesh/wrapped string?

- How has the string held up over time,

@Badgertooth or

@brooksie967? I'm curious if you've had to remove any layers while flattening, and if so, how much of a mess it was.

- Is reinforcement overkill for a stone with no visible cracks? Maybe dealing with water intrusion and evaporation the biggest factor, and a few coats of varnish/urethane is good enough. Will I see problems slowly appear or should I go for overkill now to prevent unforeseen catastrophic cracking?

If my stone wasn't from an underwater mine I wouldn't be so worried about it. But then again, my family is catholic so unnecessary worry gives my life meaning.