tostadas

Hobbyist / Craftsman

At one point, I was looking for a Yoshikane, but with some changes. I liked the grind that effortlessly falls through everything, the Sanjo style taper, and the forward balance. But if they could also make one that was taller and not so flat… wouldn’t that be perfect? Well, I think I’ve found just that in the Hatsukokoro Koromebi.

Intro

I got this knife mainly because of the advertised specs: approx 240x55, midweight, nice steel, cool looking finish. It’s available from a number of retailers, the one I have in particular with a nice handle from K&S. After testing it out for a while, there are a lot of things I like about this, and some things I think can be improved.

Specs

Blue#2 core w/ soft iron cladding

K&S Teak/Horn handle

Blade Length: 245mm

Height at Heel: 56mm

Weight: 218g*

Balance from Heel: 35mm* forward

*With 210mm “thick gyuto” teak handle

Spine Thickness

Thickness Behind the Edge at Midpoint

Geometry/Performance

The maker is not disclosed, but if you handed me this knife to use and provided no other info, I’d say it was Yoshikane. There’s a gradual taper from a respectable 4.1mm out of the handle down to a stupidly thin 0.6mm toward the tip. The edge profile features roughly 2.5inch flat spot at the heel that transitions with a gentle curve to a fairly standard tip height of approx 19mm. There is plenty of flat spot for push cutting, but not as excessive as on the Yoshi.

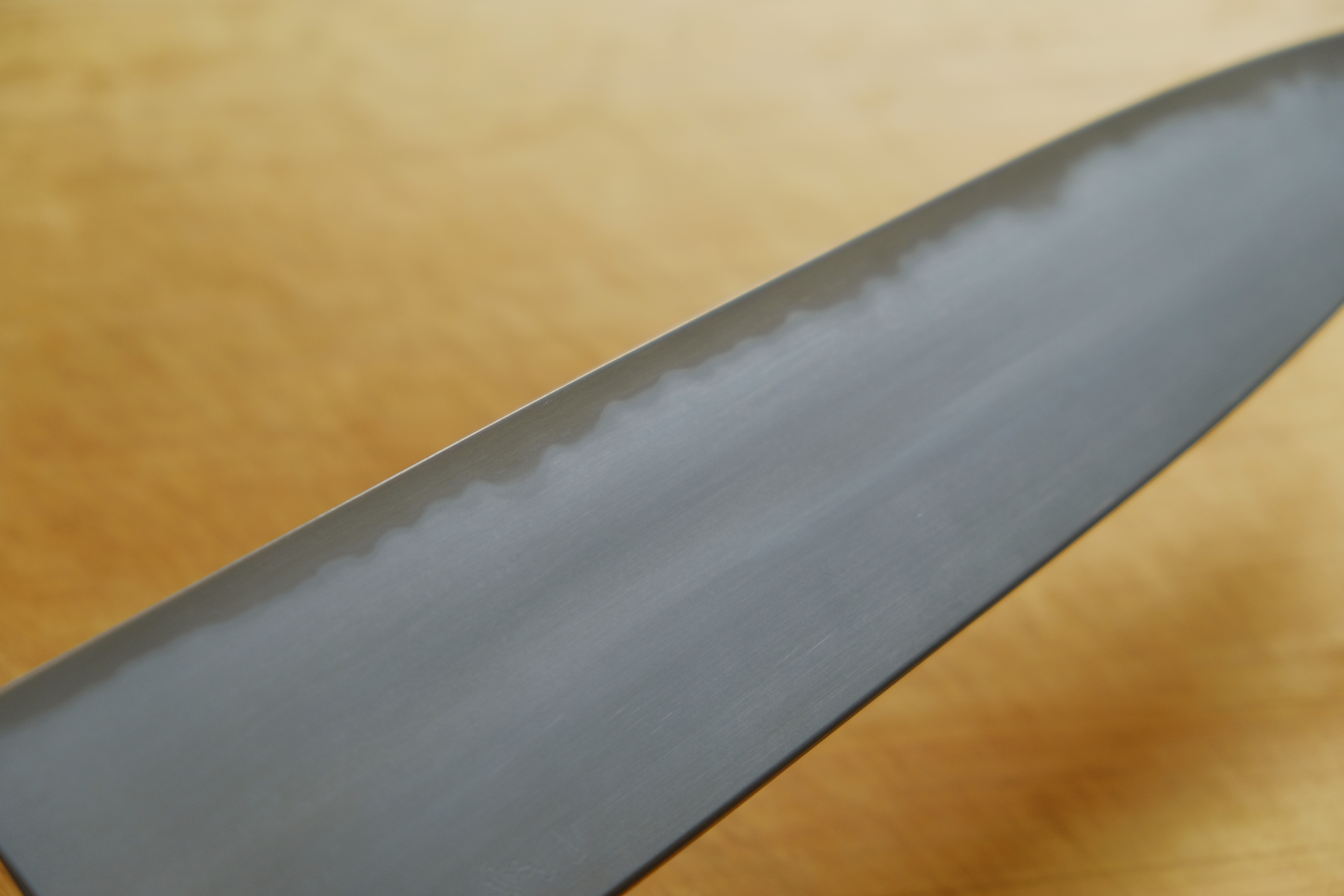

The grind seems strikingly similar to Yoshikane. High, consistent, even grind on both sides that’s near flat, or ever so slightly concave with a defined shinogi line. Behind the edge thickness is nail-flexing thin. It falls through everything with little to no effort. The blade has a polished, brushed finish which is ease to care for. There is a quick and dirty kasumi finish that is decent. Feels better than a sandblast finish and doesn’t cause unnecessary drag, though I’d prefer it to be a bit smoother.

Fit, Finish & Aesthetics

The spine and choil are eased slightly. There are no square edges, but I think it could use some additional refinement, especially right at the choil curve area. The kanji is engraved (not screened on), but doesn’t look like it’s done by hand with a chisel. More like a computer controlled engraving I’ve seen somewhere on a nice Japanese knife, but can’t put my finger on which. The finish on the blade feels refined like on many Sakai knives. I mentioned the kasumi finish earlier which is decent but not amazing. The handle I have installed is teak/horn from K&S. I prefer a thicker grip, so I got the “thick gyuto” version in a shorter 210mm size to keep the balance more forward. K&S always has the cleanest installs with minimal gap between the tang and handle, so I highly recommend getting one. The handle is shaped consistently on all sides, but there’s a noticeable lip between the wood and the horn on mine. I plan on refinishing the handle anyways, maybe also torching the teak, so having that lip is no big deal for me.

Closing Thoughts

This knife is an amazing value for the price. It really feels to me like an improved version of a Yoshikane in every way. I’m going to make some additional F&F improvements to it and see if this can earn a permanent spot in my rotation.

If anyone else has tried one of these, I’m interested to hear your thoughts as well.

Intro

I got this knife mainly because of the advertised specs: approx 240x55, midweight, nice steel, cool looking finish. It’s available from a number of retailers, the one I have in particular with a nice handle from K&S. After testing it out for a while, there are a lot of things I like about this, and some things I think can be improved.

Specs

Blue#2 core w/ soft iron cladding

K&S Teak/Horn handle

Blade Length: 245mm

Height at Heel: 56mm

Weight: 218g*

Balance from Heel: 35mm* forward

*With 210mm “thick gyuto” teak handle

Spine Thickness

Handle | Heel | Midpoint | 1cm from tip |

4.1mm | 3.7mm | 2.3mm | 0.6mm |

Thickness Behind the Edge at Midpoint

@1mm | @5mm | @10mm | @20mm |

0.1mm | 0.5mm | 0.8mm | 1.6mm |

Geometry/Performance

The maker is not disclosed, but if you handed me this knife to use and provided no other info, I’d say it was Yoshikane. There’s a gradual taper from a respectable 4.1mm out of the handle down to a stupidly thin 0.6mm toward the tip. The edge profile features roughly 2.5inch flat spot at the heel that transitions with a gentle curve to a fairly standard tip height of approx 19mm. There is plenty of flat spot for push cutting, but not as excessive as on the Yoshi.

The grind seems strikingly similar to Yoshikane. High, consistent, even grind on both sides that’s near flat, or ever so slightly concave with a defined shinogi line. Behind the edge thickness is nail-flexing thin. It falls through everything with little to no effort. The blade has a polished, brushed finish which is ease to care for. There is a quick and dirty kasumi finish that is decent. Feels better than a sandblast finish and doesn’t cause unnecessary drag, though I’d prefer it to be a bit smoother.

Fit, Finish & Aesthetics

The spine and choil are eased slightly. There are no square edges, but I think it could use some additional refinement, especially right at the choil curve area. The kanji is engraved (not screened on), but doesn’t look like it’s done by hand with a chisel. More like a computer controlled engraving I’ve seen somewhere on a nice Japanese knife, but can’t put my finger on which. The finish on the blade feels refined like on many Sakai knives. I mentioned the kasumi finish earlier which is decent but not amazing. The handle I have installed is teak/horn from K&S. I prefer a thicker grip, so I got the “thick gyuto” version in a shorter 210mm size to keep the balance more forward. K&S always has the cleanest installs with minimal gap between the tang and handle, so I highly recommend getting one. The handle is shaped consistently on all sides, but there’s a noticeable lip between the wood and the horn on mine. I plan on refinishing the handle anyways, maybe also torching the teak, so having that lip is no big deal for me.

Closing Thoughts

This knife is an amazing value for the price. It really feels to me like an improved version of a Yoshikane in every way. I’m going to make some additional F&F improvements to it and see if this can earn a permanent spot in my rotation.

If anyone else has tried one of these, I’m interested to hear your thoughts as well.