Defiantly a unique inquiry.

Looking for an 'expensive' grind, on a cheap steel/blade & handle.

Looking for an 'expensive' grind, on a cheap steel/blade & handle.

It is actually a sharpener and not just a "straightener" like a butcher's steel is

Probably a bad idea to put my immersion circulator in ferric chloride, right?

Best to use a magnetic induction circulator outside the tank, you can get a USSR surplus one for cheap from any of the military surplus outlets around Vilnius.

Please take any "dishwasher safe" parameters out of consideration. REALLY. It is not pertinent to sharp knives at the present level of materials science.

You should never expose a good knife to such treatment, even if any knife alloy could take the chemical/heat/corrosion issues in stride, it would be physically destructive to cutting edges from being banged against whatever else is in the dishwasher (steel, glass, ceramics).

I can definitely see how my inquiry could be considered trolly in a forum of hobbyists, but I legit just want a cheap knife with an S-grind. Like stamped out of sheet metal, rubber handle, S-grind.

Honestly, if someone can recommend a cheap, thick knife, I'll take that too. I have quite a bit of seat-time piloting a Dremel.

I masked off the upper and lower blade face in clear nail polish then layers of blue tape. its a messy imperfect process that needs a lot of clean up with hand work, but is doable if you want it bad enough.Wow, interesting. Does that take forever? Do you keep circulating ferric chloride over it in a little river?

Does anyone have a lead on a 6-8" chef's knife with an S-grind in the sub $100 range?

Did you by chance get any pictures of the grinding process?

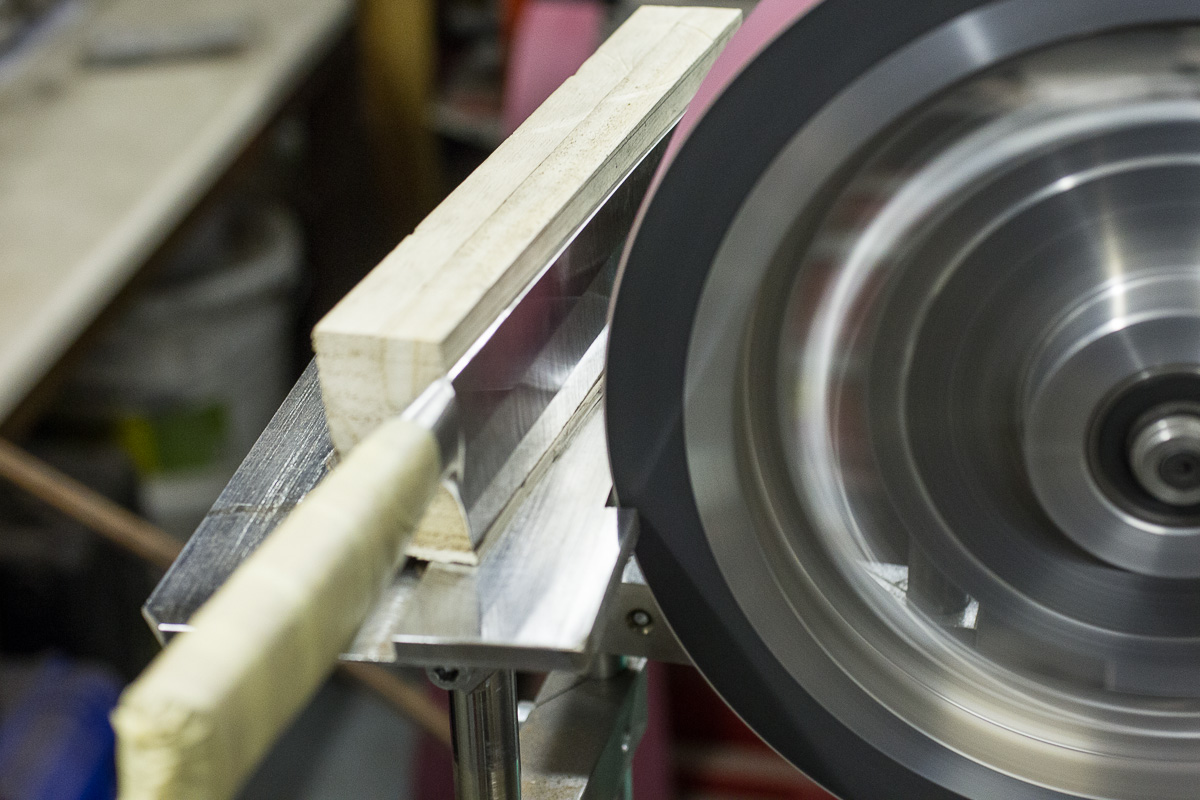

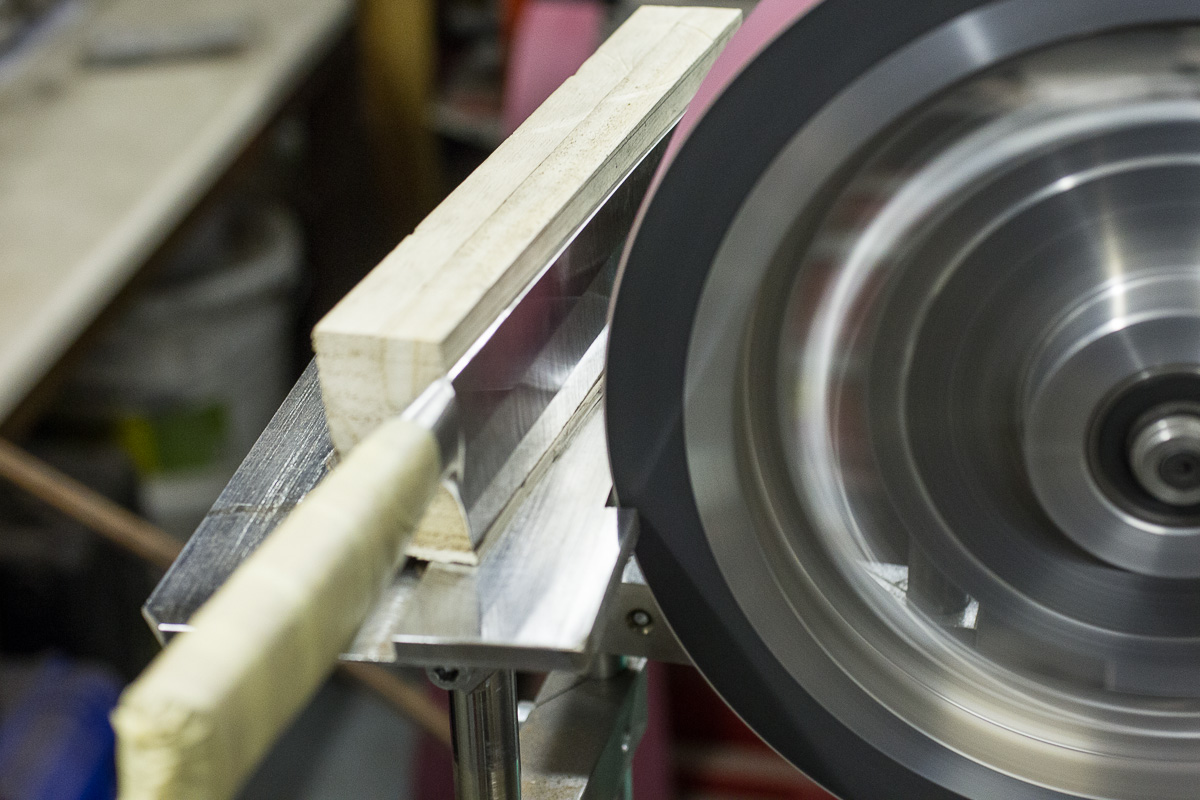

convex thinning on rotary platen

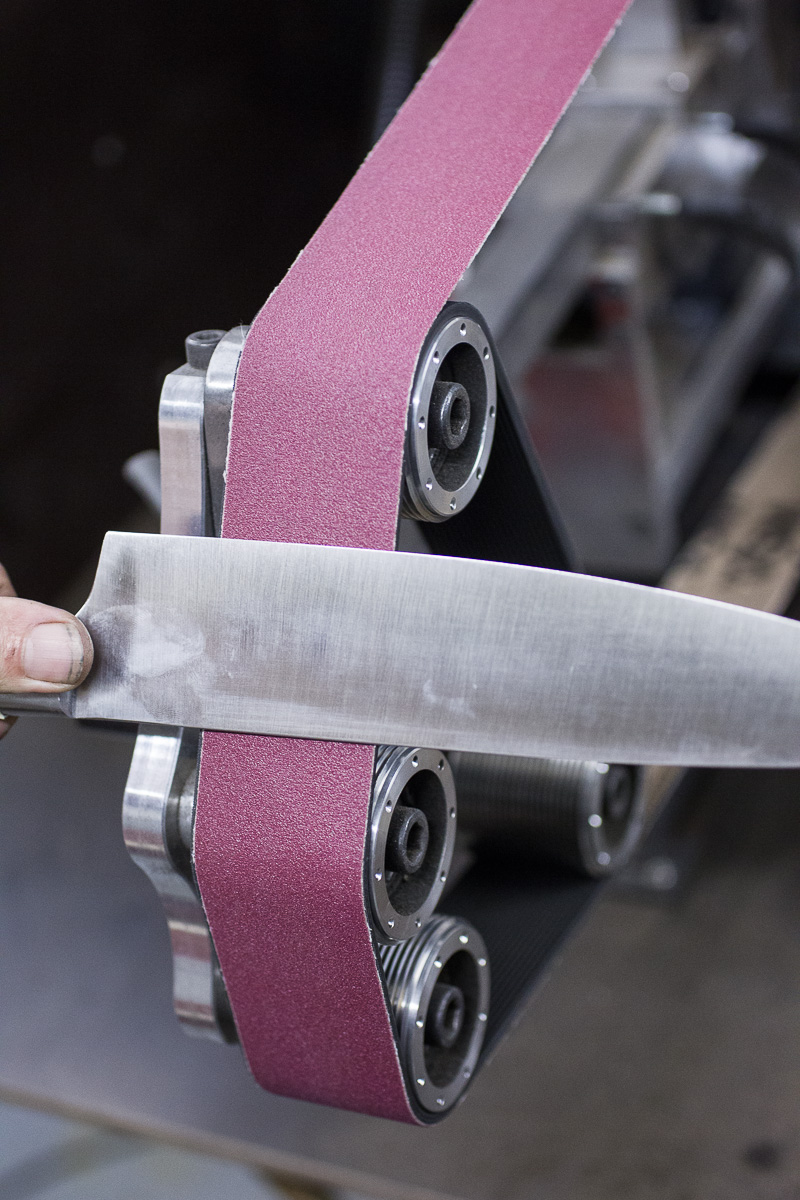

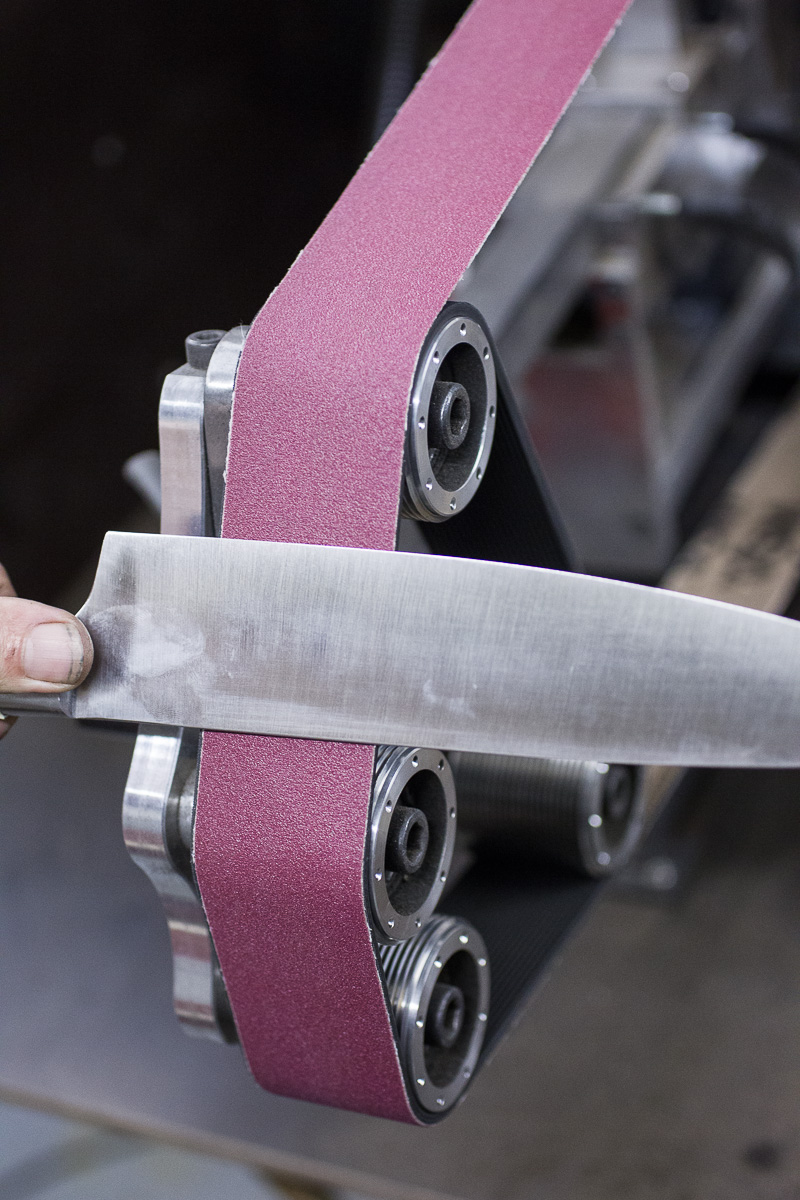

Fast hollow grinding for the s-shape using a jig with 60 grit belt

Foodrelase would be better with the hollow grind closer to the edge, but this way the knife has more lifespan for resharpenenig and maybe chip removal before touching the hollow part

Regards

Uwe

Enter your email address to join: