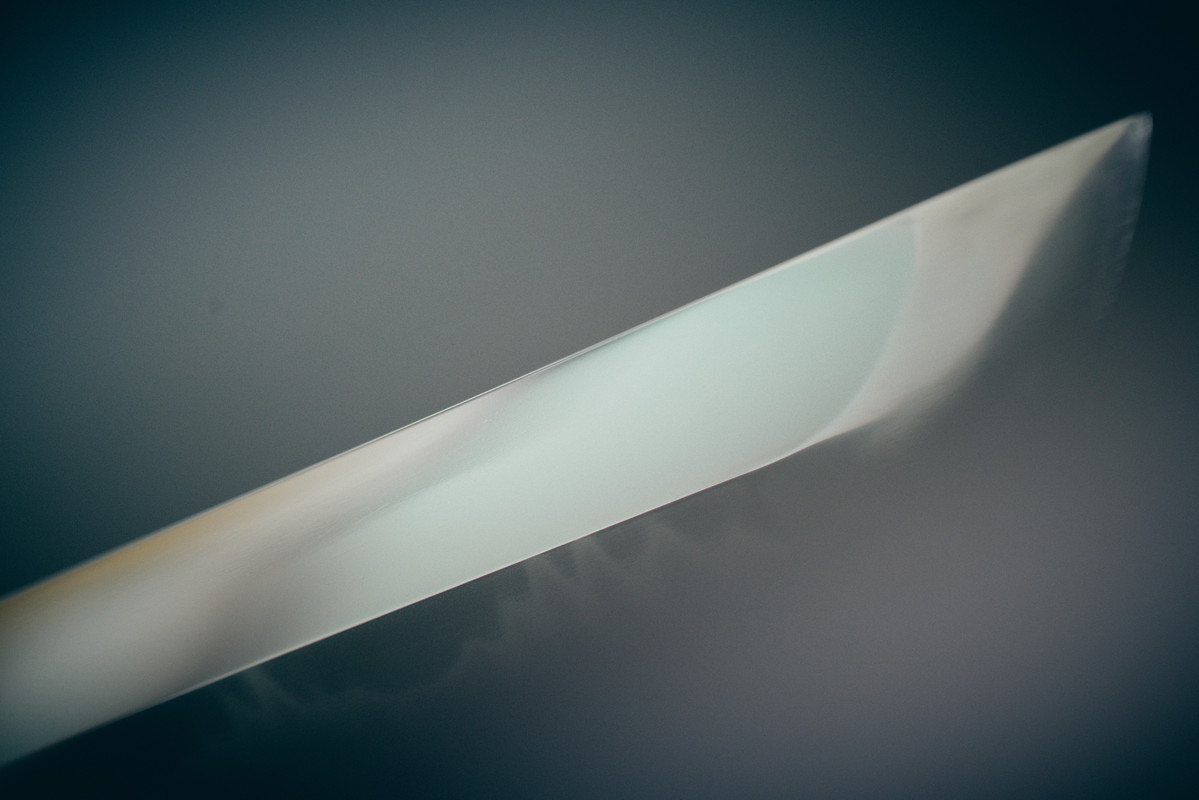

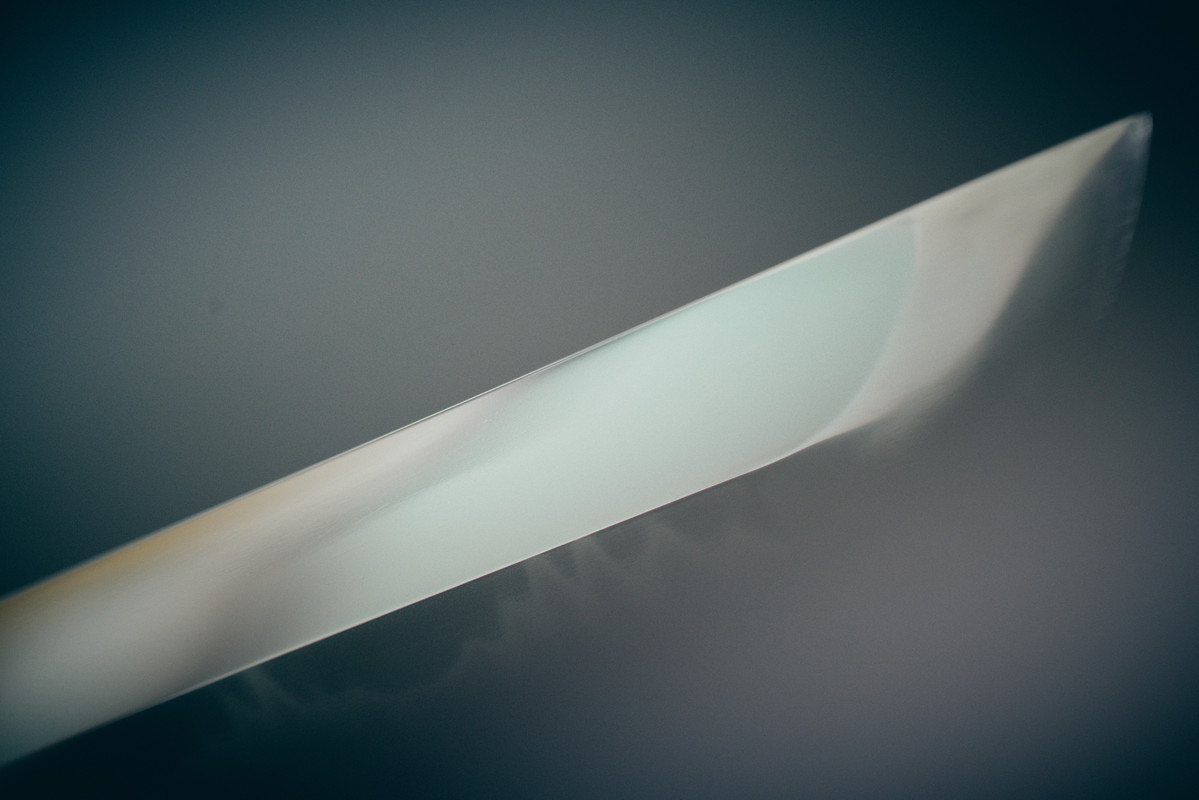

the Kuzan Oda yanagiba, 360mm, honyaki

I was afraid of not being able to get this blade done with good conscience. This made me almost angry because of the efforts put in it..

The sword-looking blade is now going back to its owner.

You are probably thinking it was easy.

Those who tried to polish a honyaki may have noticed how hard it is. And how time consuming it is.

You can try to imagine this very hard and tough steel, resisting to pressure on coarse diamond plates. And when you put it on finer stones and JNATS, you can imagine the little quantity of metal you're removing after each stroke...

And it sounds like you feel frustrated because the iron clad you polished before felt like melted butter in comparison.

On your kasumi you gave 20% of the work and get 80% of the result. An invitation to trade offs and it's still more than good enough.

Same with honyaki? Unfortunately not.

You give 20% and get nothing .

You are hardworker and at a point you're feeling to be at 99%. (When you're close to give up and the result begins to be "not bad")

So what's the next best step?

When you polish a knife, you can take the easy way and make the whole blade look mirror. Idiot proof, the scratches remain always but are not that visible a couple of feet away.

And your blade became featureless.

Are you giving up on getting a sword-like finish?

"No way!"

The good thing, if you don't work for a museum: you can feel free to polish the way you want

Anyway, there are some kind of "rules" you have to be aware of.

_General geometry

*

_As scratch free as possible when you look the blade at minimum distance (15-20cm) *

_Shinogi as a clear line and sharpest as possible (highest acutance)

* * *

_Sharp delimitation in color, texture and geometry at the tip (strictly perpendicular)

* * *

_Bevel with feeling of exact homogeneous height from heel to tip

*

_Whitish below the hamon line but not shiny

* * *

_Dark above the hamon line but not too shiny

* * *

_Dark mirror above the shinogi

*

* Impossible with full mirror finish

* Difficult with finger stones

* Important steps on bench stones. Have to be respected in further steps.

* Only with finger stones

All these points above are impossible to reach with sand paper.

Every additional box you're ticking is doubling your work.