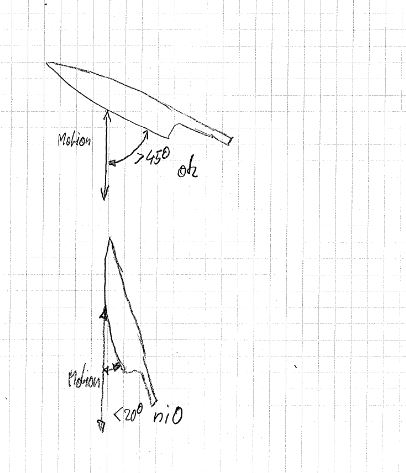

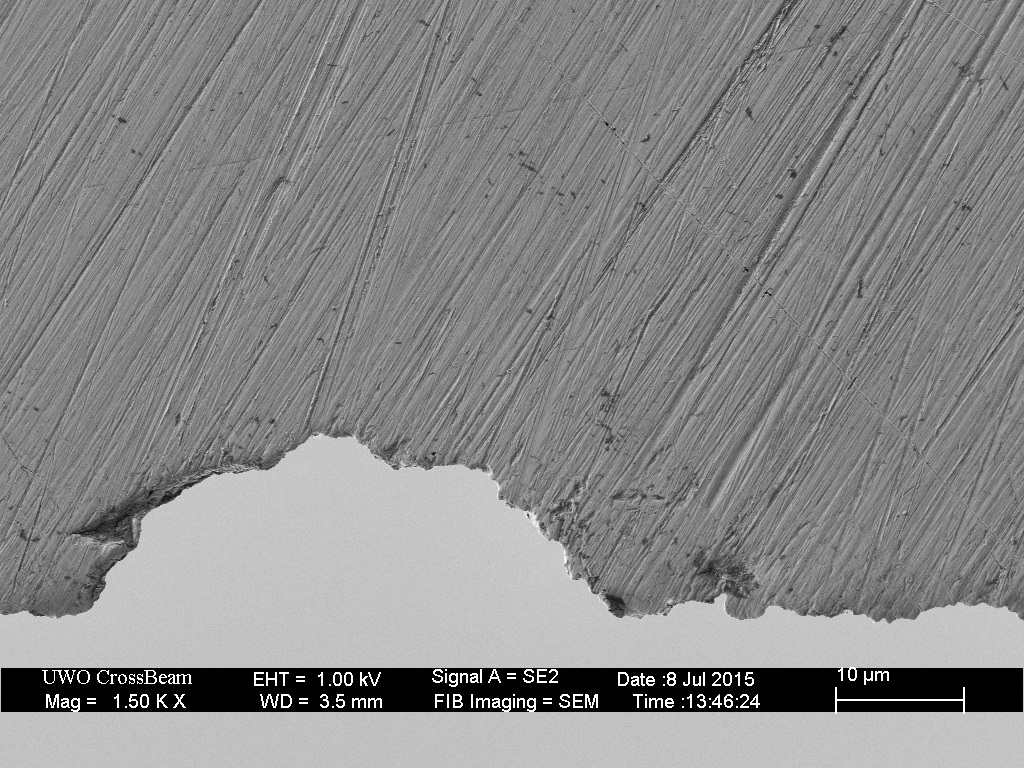

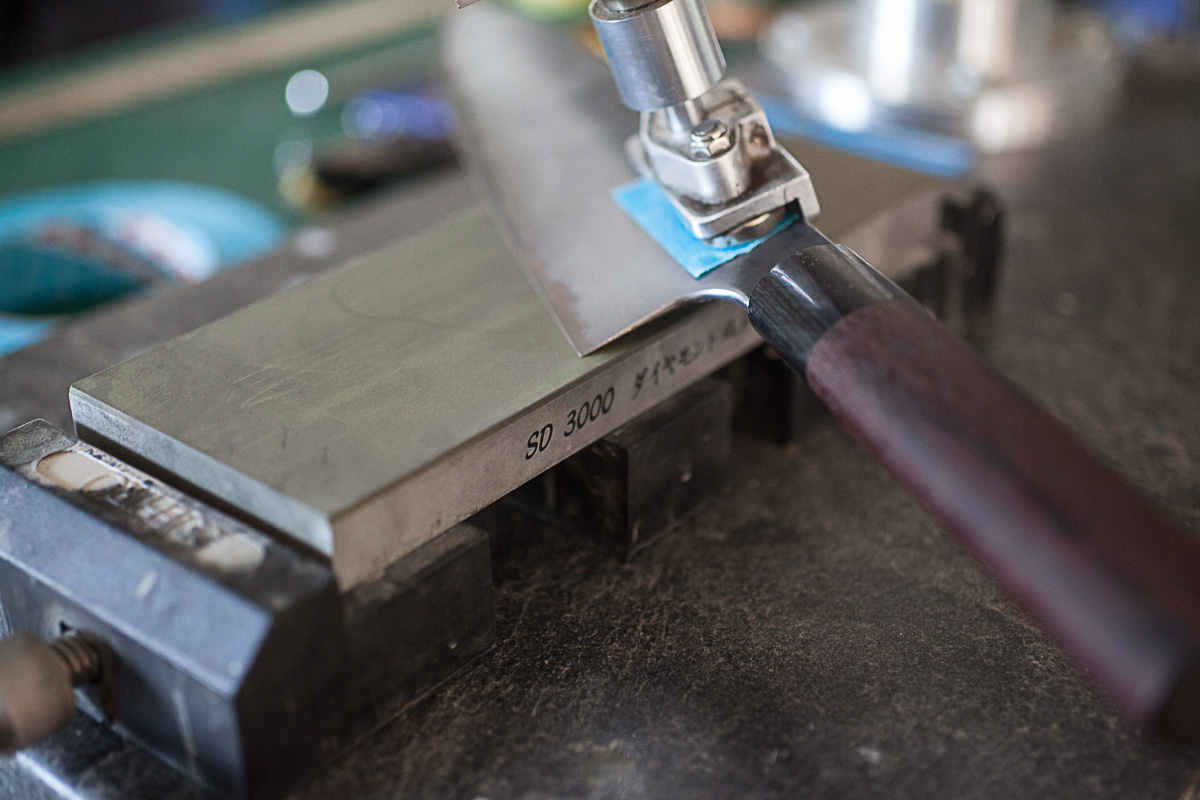

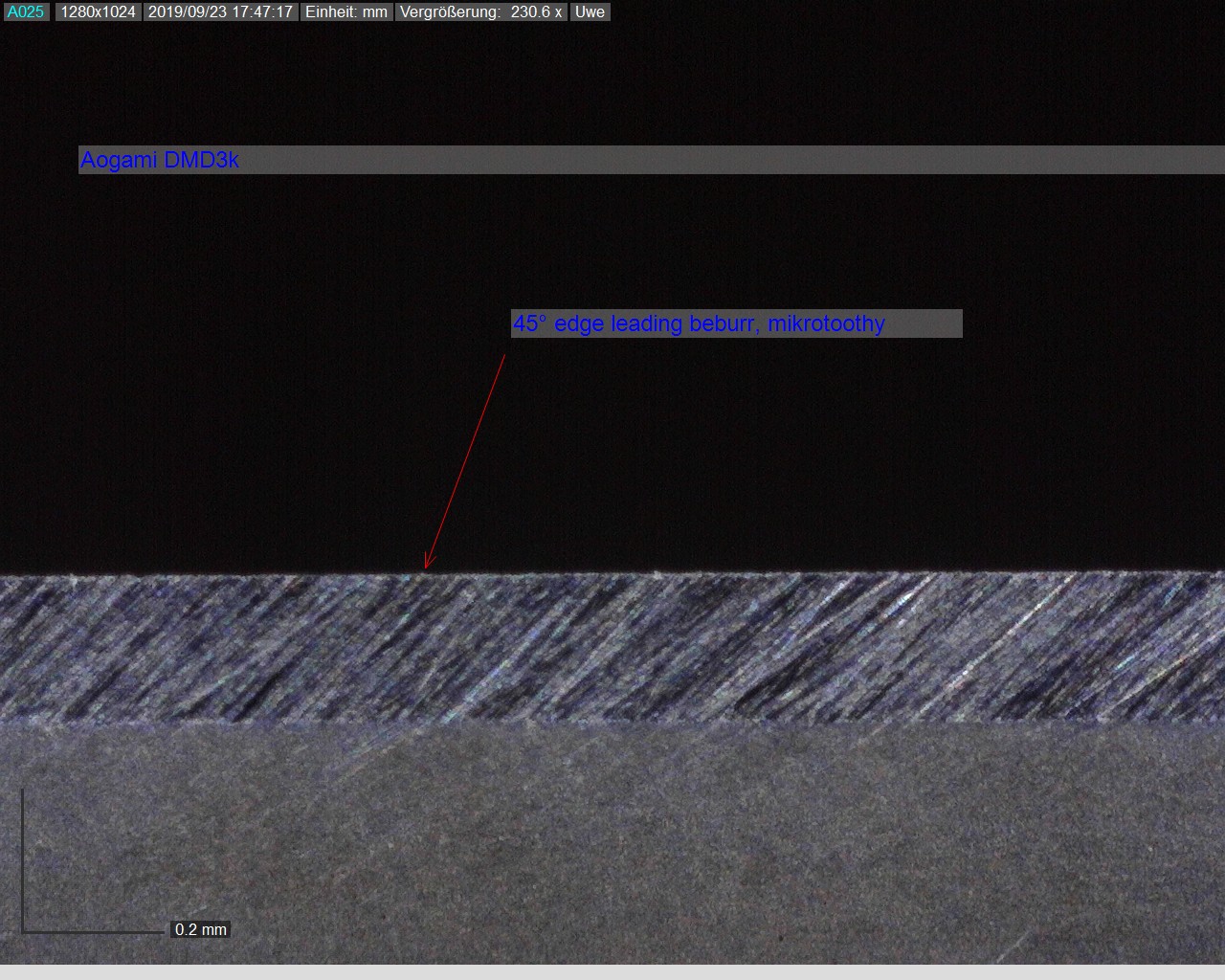

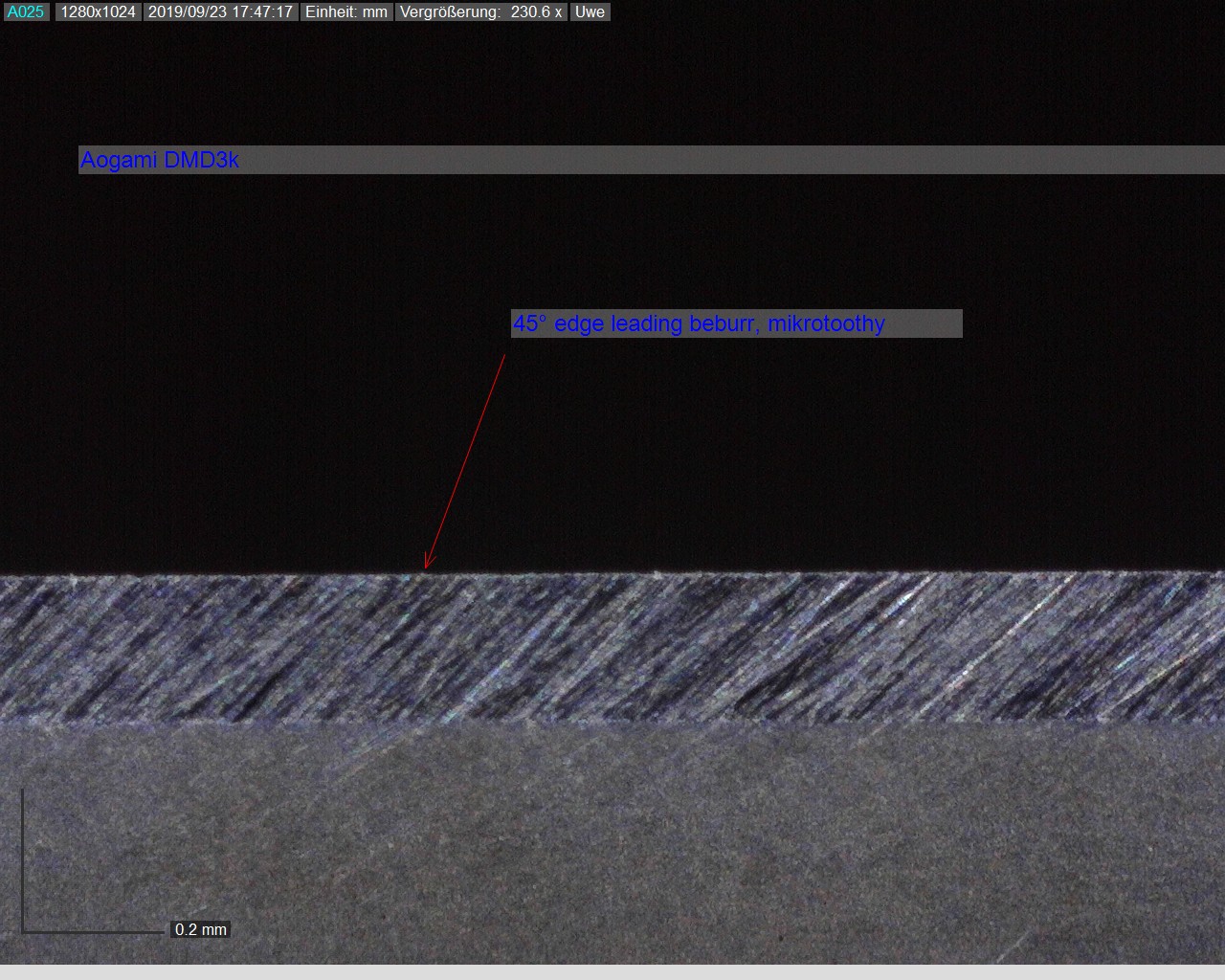

For me the best way to get rid of burrs ist to do light short strokes edge leading, like sharpening about 45° to the edge. Gives a fine mikroserration and lots of bite.

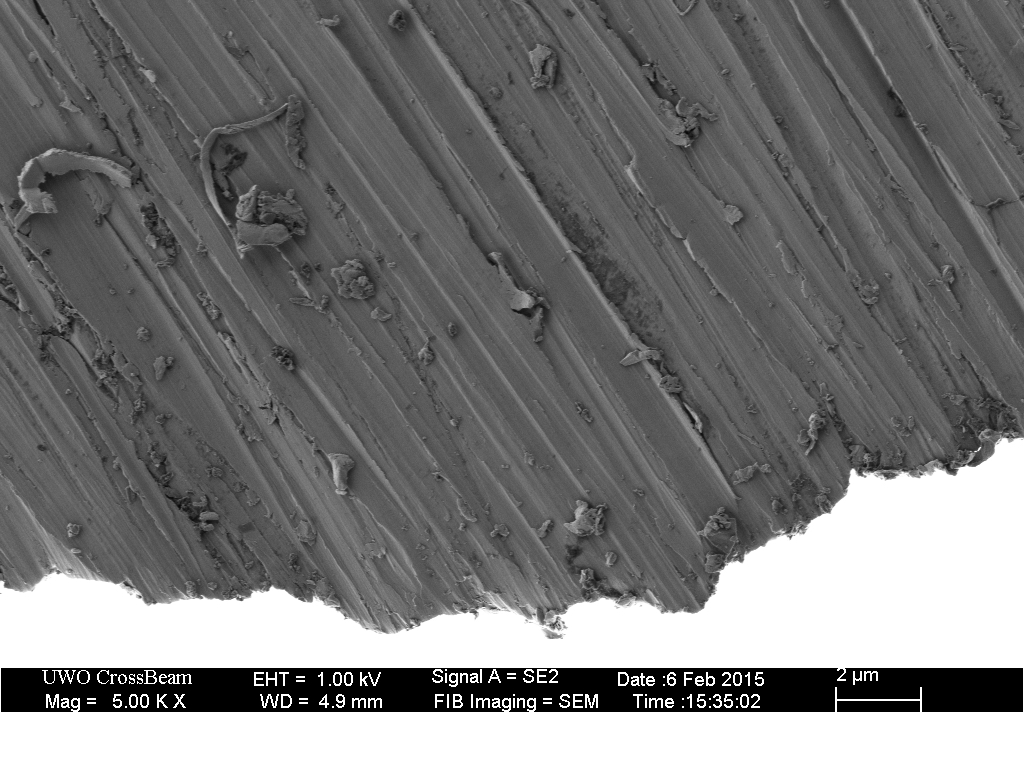

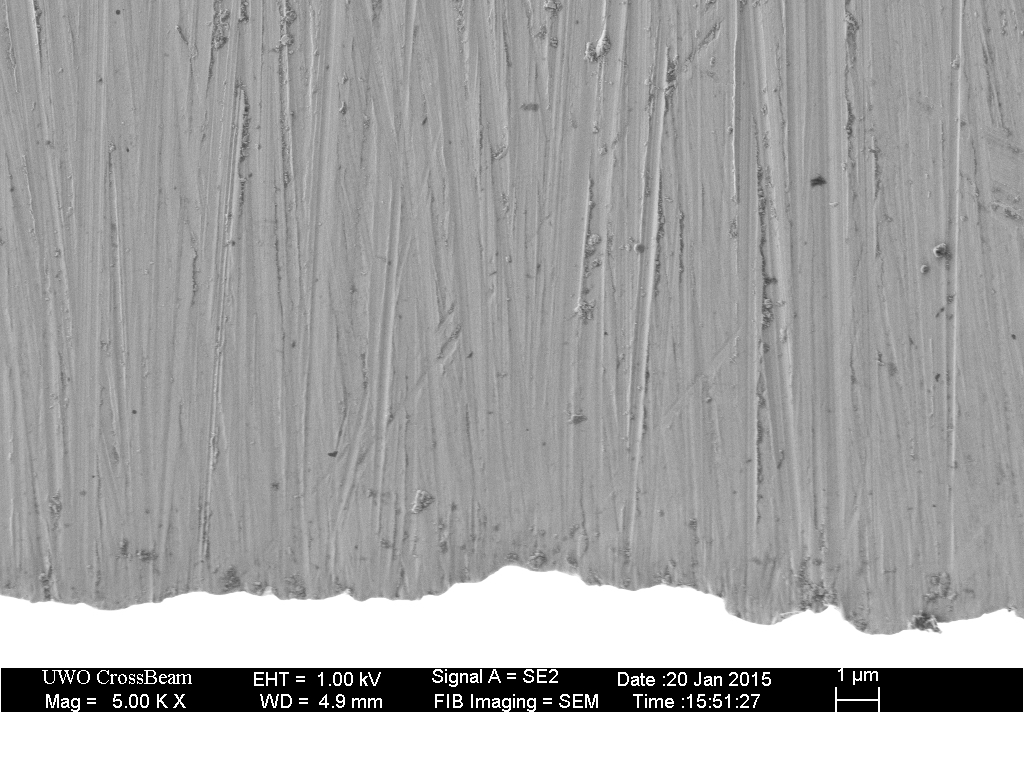

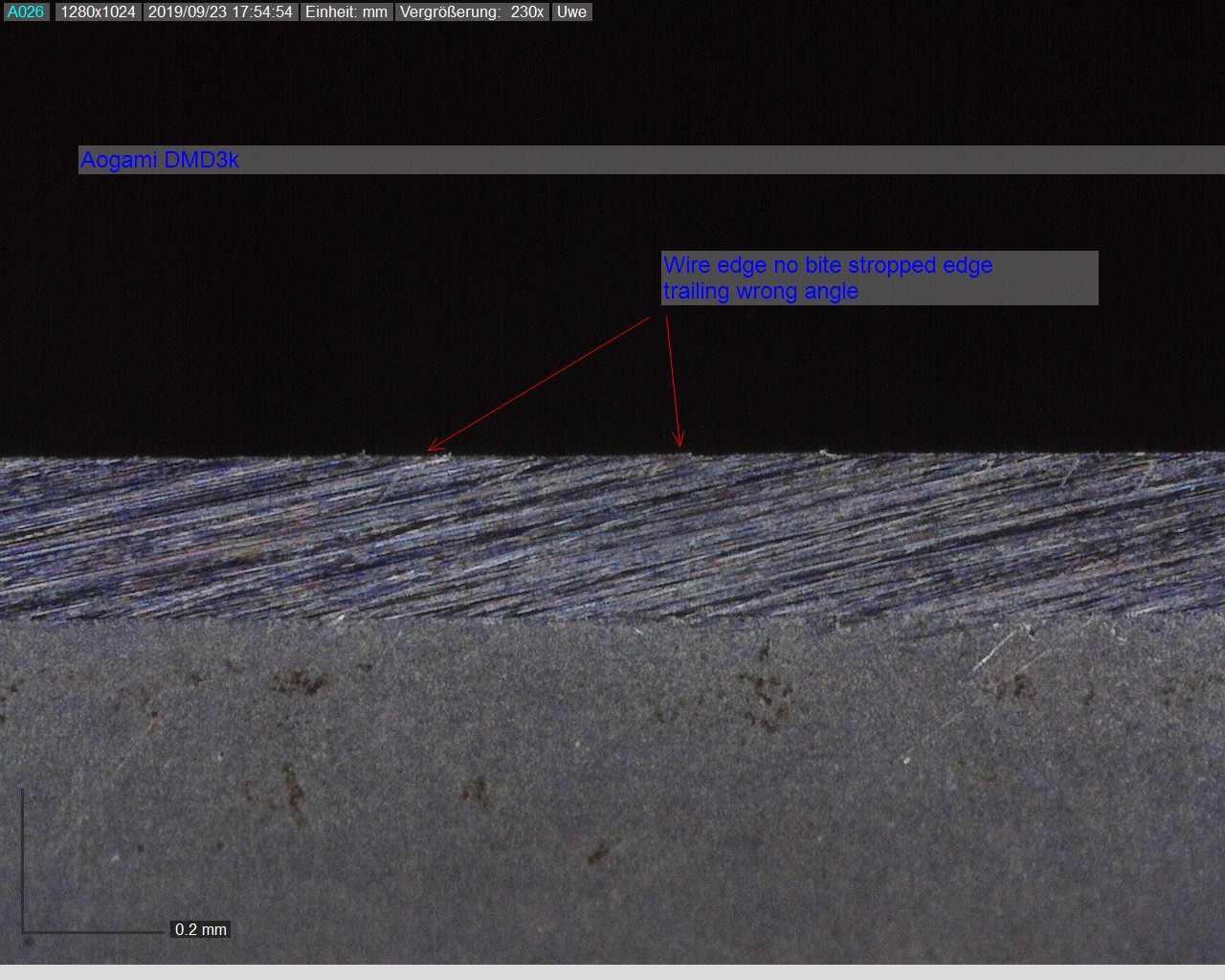

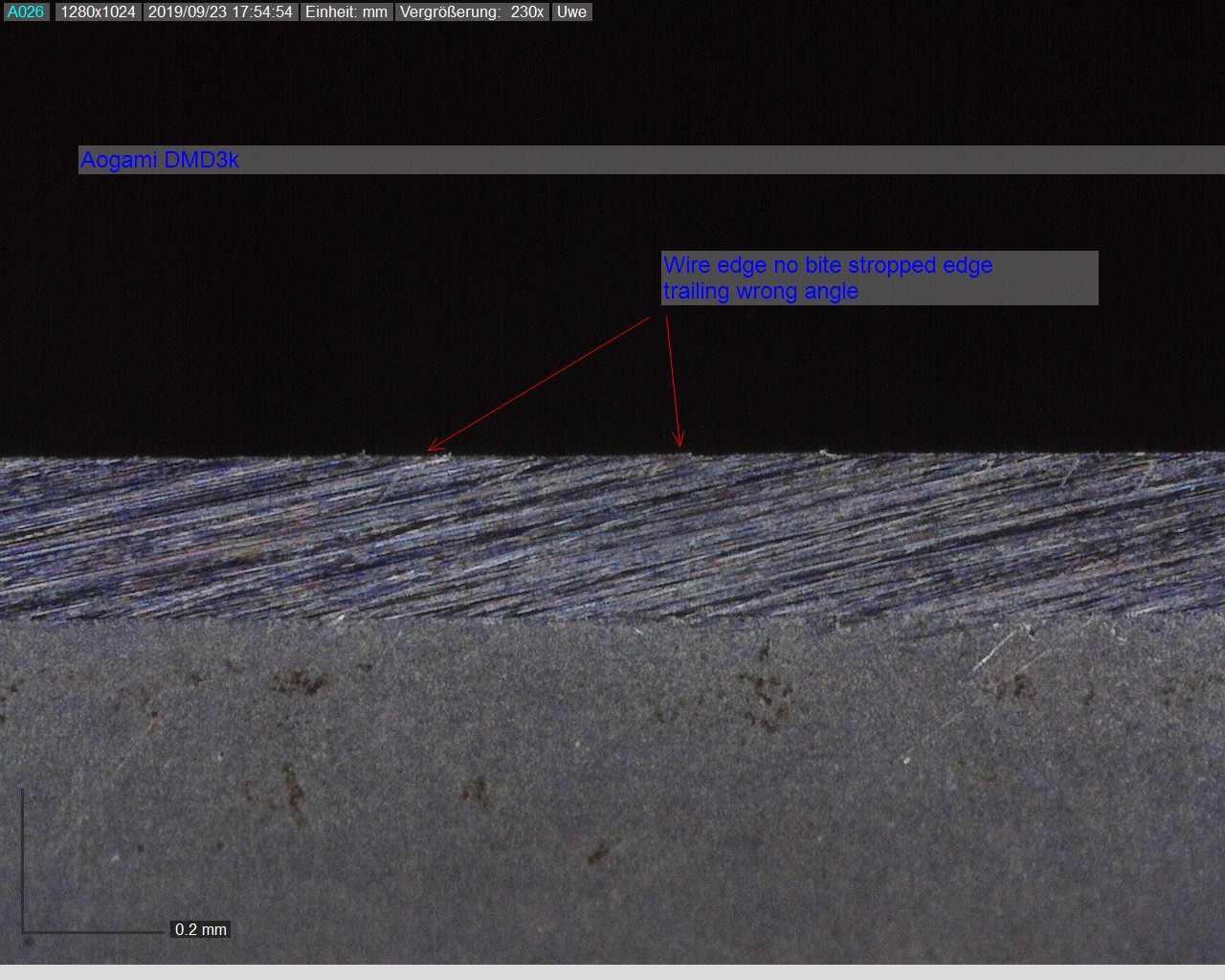

In comparison stropped edge trailing along the edge you get an wire edge with almost no bite and min. 50% less time on the board for the next touchup...

With finer stones the difference ist not so huge, but if you are looking for a toothy edge i would go with an steep angle edge leading.

Regards

Uwe

In comparison stropped edge trailing along the edge you get an wire edge with almost no bite and min. 50% less time on the board for the next touchup...

With finer stones the difference ist not so huge, but if you are looking for a toothy edge i would go with an steep angle edge leading.

Regards

Uwe