James

Senior Member

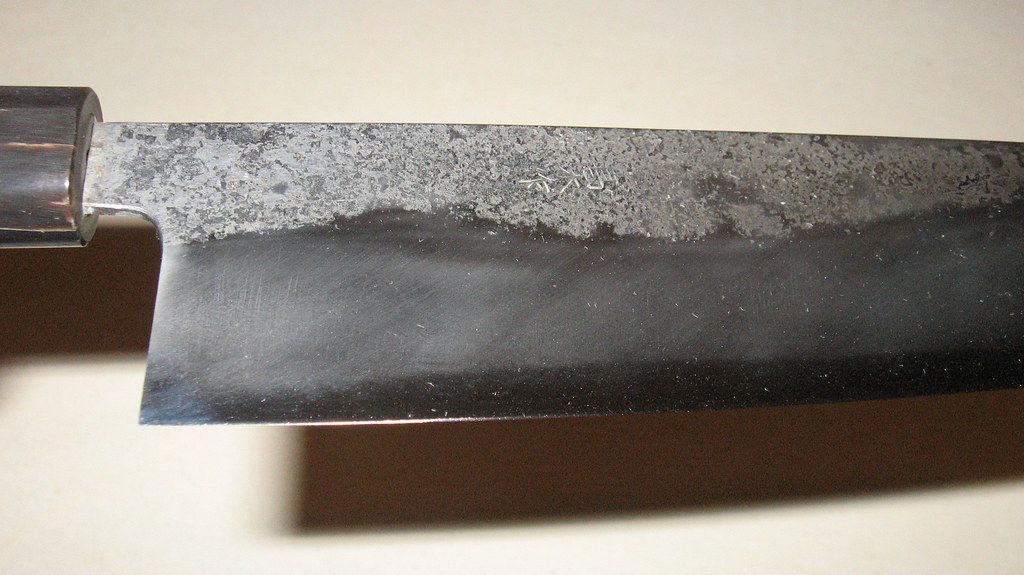

So after ordering my takagi honyaki 240 mm gyuto from JWW, it arrived today. The packing from JWW was pretty interesting; pages from their catalog crumbled up. After a few seconds of digging within the box, I found the light green box with my knife in it. The knife itself was wrapped in a cardboard saya and some anti corrosion paper (?).

Handle: typical D handle with plastic ferrule. The blade is burnt into the handle, and where the handle meets the blade, there's decently sized gap, which I will later need to fill in with epoxy...I may just get a rehandle.

Blade: honyaki aogami #1. The blade is pretty darn thick, the edge isn't evenly ground, and isn't up to my standard for sharpness; the blade could not shave cleanly in both directions or whittle hair. This left me with a few problems, as the steel is extremely abrasion resistant. Starting with the togiharu 1k/4k combo stone and finishing on the arashiyama 6k, bringing just the edge up to scratch took a good 1/2 hr. Thinning this knife scares me a bit.

I used the knife briefly (10-15 min today) to whip up a corn chowder. The knife discolored onions for a few cuts and failed to react after those initial slices; I also noticed some wedging issues with whole potatoes, but otherwise, it did a decent job.

Side note for those interested: The knife balances about 3-4" in front of the ferrule.

Next step: THINNING...I wonder if I can send this off to Dave; I can see getting returned the knife with a note saying "thanks, but I don't want carpal tunnel".

Handle: typical D handle with plastic ferrule. The blade is burnt into the handle, and where the handle meets the blade, there's decently sized gap, which I will later need to fill in with epoxy...I may just get a rehandle.

Blade: honyaki aogami #1. The blade is pretty darn thick, the edge isn't evenly ground, and isn't up to my standard for sharpness; the blade could not shave cleanly in both directions or whittle hair. This left me with a few problems, as the steel is extremely abrasion resistant. Starting with the togiharu 1k/4k combo stone and finishing on the arashiyama 6k, bringing just the edge up to scratch took a good 1/2 hr. Thinning this knife scares me a bit.

I used the knife briefly (10-15 min today) to whip up a corn chowder. The knife discolored onions for a few cuts and failed to react after those initial slices; I also noticed some wedging issues with whole potatoes, but otherwise, it did a decent job.

Side note for those interested: The knife balances about 3-4" in front of the ferrule.

Next step: THINNING...I wonder if I can send this off to Dave; I can see getting returned the knife with a note saying "thanks, but I don't want carpal tunnel".