milkbaby

Well-Known Doofus

Not much to show but I was just so happy that I got to a major point in the process of making these knives that I thought I would post!

Four weeks ago I hacksaw rough cut two knives out of 15N20 steel 3/32" thick. This western chef was a design I came up with after being so happy with the result of another western chef I made for friends. It has even more belly towards the tip for rocking, totally different from what I usually dig.

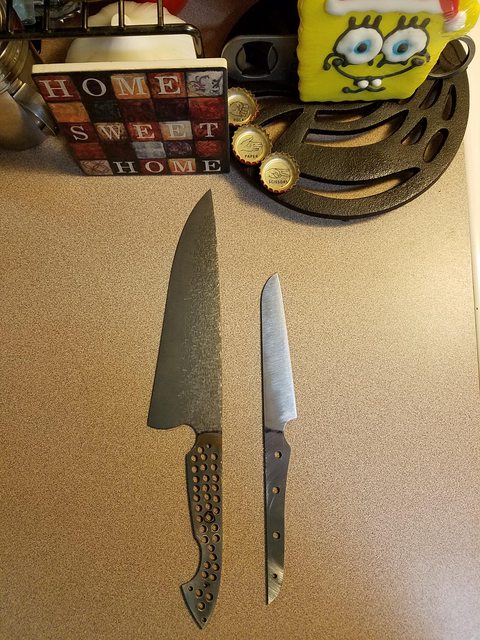

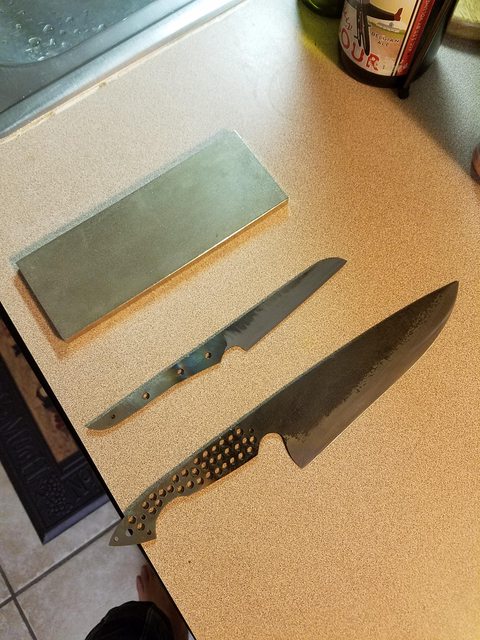

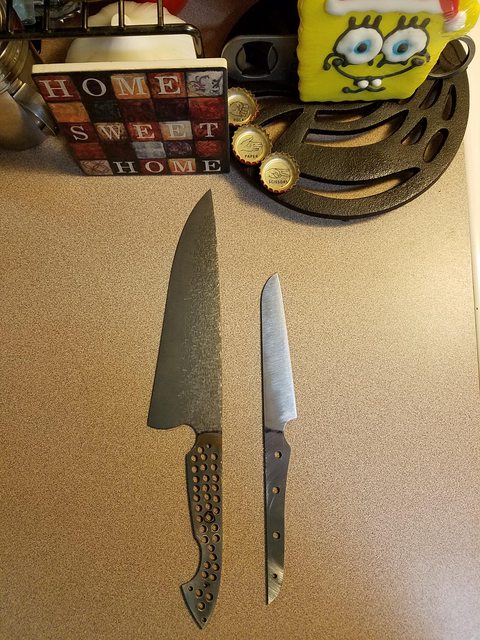

The western chef that I made for a couple dear friends:

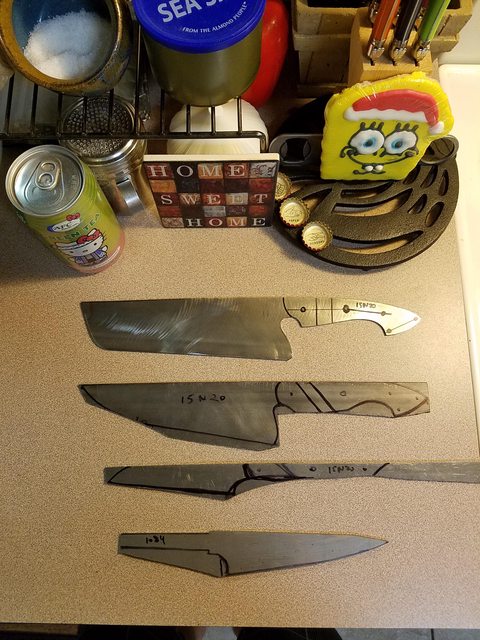

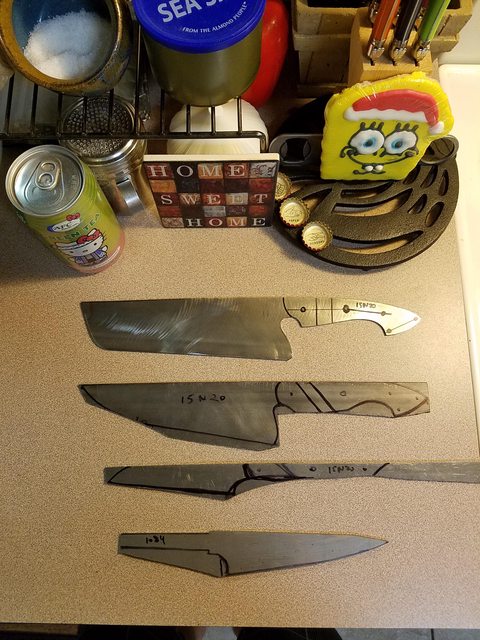

The western chef with more belly rough profiled. Plus my sister has been bugging me for a paring/small utility knife, so I drew one onto a leftover off cut piece of metal. Waste not, want not. Also in this pic is a hidden tang utility that I've had partially profiled but had sitting around since last year...

After a little profiling and drilling and grinding when I had a spare moment during the last four weeks, I finally had enough free time today to get these durn things mostly ground, at least enough to heat treat next. A major pain on my 1x30" belt grinder, especially since I should've gone to a new belt instead of spending so much time slowly grinding with an old one. Doing a beefier grind without much distal taper, kind of an experiment for me.

During the four weeks of barely doing anything, I also picked the wood and glued up the scales for the chef's knife. It's a pain making multipart handle scales, especially with metal liners and spacers, but that stuff looks so nice when finished that I can't resist.

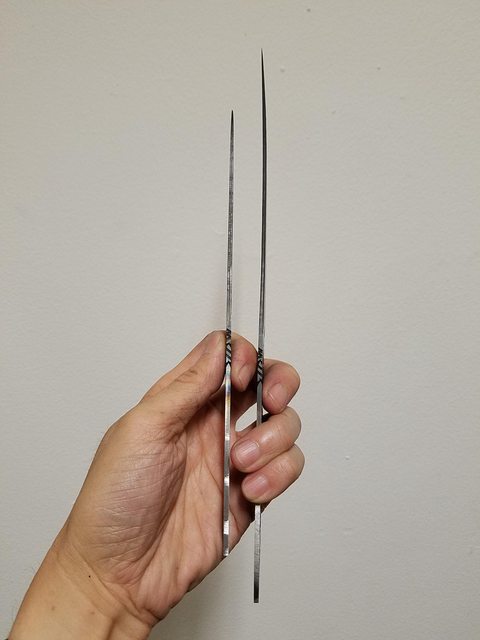

Obligatory Spongebob appearance:

Four weeks ago I hacksaw rough cut two knives out of 15N20 steel 3/32" thick. This western chef was a design I came up with after being so happy with the result of another western chef I made for friends. It has even more belly towards the tip for rocking, totally different from what I usually dig.

The western chef that I made for a couple dear friends:

The western chef with more belly rough profiled. Plus my sister has been bugging me for a paring/small utility knife, so I drew one onto a leftover off cut piece of metal. Waste not, want not. Also in this pic is a hidden tang utility that I've had partially profiled but had sitting around since last year...

After a little profiling and drilling and grinding when I had a spare moment during the last four weeks, I finally had enough free time today to get these durn things mostly ground, at least enough to heat treat next. A major pain on my 1x30" belt grinder, especially since I should've gone to a new belt instead of spending so much time slowly grinding with an old one. Doing a beefier grind without much distal taper, kind of an experiment for me.

During the four weeks of barely doing anything, I also picked the wood and glued up the scales for the chef's knife. It's a pain making multipart handle scales, especially with metal liners and spacers, but that stuff looks so nice when finished that I can't resist.

Obligatory Spongebob appearance: